Yard Gantry Solutions for Efficient Material Handling and Transportation

Exploring the Essence of Yard Gantries Bridging Functionality and Design

In the ever-evolving landscape of industrial and construction environments, yard gantries stand as a testament to engineered efficiency and innovative design. These towering structures, often overlooked in discussions of modern architecture, play crucial roles in shaping the workflows of various industries, from shipping yards to manufacturing plants. This article explores the multifaceted nature of yard gantries, delving into their design, functionality, and relevance in today’s world.

Understanding Yard Gantries

Yard gantries are large, mobile or stationary structures designed to lift and transport heavy loads across designated areas. Typically made from steel or reinforced materials, these gantries can range in size from small models used in workshops to massive frameworks found in shipping ports. Their design allows for the seamless movement of materials, minimizing the need for manual labor and enhancing workplace safety.

The primary function of a yard gantry is to provide a mechanical means of lifting and moving goods, such as containers, machinery, or raw materials. By utilizing cranes, hoists, or other lifting mechanisms, yard gantries streamline operations, enabling quicker turnaround times in busy environments. This efficiency is critical in sectors where time is money, such as logistics and manufacturing.

Historical Context and Evolution

The concept of the gantry is not new; its roots can be traced back to the early days of industrialization. Originally, simple overhead frames were used to facilitate the manual lifting of heavy items. As technology progressed, so did the design and functionality of yard gantries. The introduction of electrical winches, pneumatic systems, and automated controls has revolutionized how these structures are employed in modern settings.

Today, advanced materials and engineering techniques allow for the construction of stronger, lighter, and more versatile gantries. Innovations such as modular designs enable companies to customize their gantries according to specific job requirements or spatial constraints. Additionally, the integration of smart technology—such as sensors for load monitoring and automated positioning—enhances safety and operational efficiency.

Design Elements and Considerations

yard gantry

The design of yard gantries encompasses several critical aspects that ensure they are effective for their intended purpose. Key considerations include load capacity, height, reach, and stability. Manufacturers often employ computer-aided design (CAD) software to simulate structural performance under various conditions, which aids in optimizing their designs for durability and reliability.

One of the most significant trends in gantry design is the focus on versatility. Many contemporary gantries are designed with adjustable heights and modular components, allowing them to adapt to different lifting tasks. This flexibility is especially valuable in environments where the nature of work may change frequently, as it reduces downtime and increases return on investment.

Safety Standards and Regulations

With the heavy lifting capabilities of yard gantries comes the critical need for adherence to safety standards. Regulatory bodies establish guidelines that govern the design, operation, and maintenance of these structures to protect workers and prevent accidents. Regular inspections, operator training, and proper maintenance protocols are essential for ensuring the safe use of yard gantries.

Moreover, the integration of safety features, such as emergency stop buttons, overload sensors, and fail-safe mechanisms, has become standard practice. These innovations not only enhance the safety of the operators but also contribute to the longevity of the equipment.

Conclusion The Future of Yard Gantries

As industries strive for greater efficiency and productivity, the role of yard gantries is set to expand even further. With ongoing advancements in automation and robotics, future gantry systems may incorporate AI-driven technologies that optimize load management and enhance operational workflows. The continued push towards sustainability also influences gantry design, leading to the exploration of eco-friendly materials and energy-efficient mechanisms.

In conclusion, yard gantries are far more than mere structures; they are pivotal elements that enhance industrial performance. Their evolution reflects broader trends in technology and design, showcasing a commitment to safety and efficiency. As we look towards the future, it is clear that yard gantries will continue to play a significant role in shaping the landscape of modern industry, proving that functionality and design can indeed go hand in hand.

-

4000 lb Gantry Crane | Adjustable, Heavy-Duty Lifting SolutionsNewsAug.31,2025

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

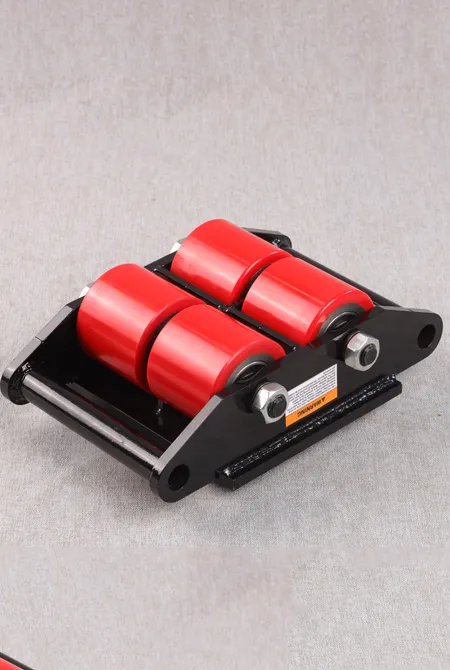

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025