magnetic lifter 500kg

The Magnetic Lifter 500kg Revolutionizing Heavy Lifting

In the world of industrial lifting equipment, efficiency and safety are paramount. The magnetic lifter, particularly the model rated for 500kg, stands out as a remarkable innovation in heavy lifting technology. This article delves into what makes the magnetic lifter an essential tool in various industries, its functionality, benefits, and safety features.

Understanding the Magnetic Lifter

A magnetic lifter utilizes powerful magnets to lift and transport ferromagnetic materials safely and effortlessly. The design of the magnetic lifter allows it to adhere firmly to flat, smooth surfaces, making it particularly suitable for handling steel plates, blocks, and other similar items. The 500kg model is engineered for moderate to heavy loads, providing a perfect balance between power and versatility.

How It Works

The core of the magnetic lifter's functionality lies in its magnetic circuit. When activated, the lifter generates a strong magnetic field that can immobilize and lift objects weighing up to 500 kilograms. The operation is typically controlled via a simple lever mechanism, which ensures that the lifting and releasing actions can be performed easily and safely. This ease of use is a significant advantage, allowing even non-experienced personnel to operate the equipment with minimal training.

Advantages of Using a Magnetic Lifter

1. Efficiency One of the most significant benefits of magnetic lifters is their ability to quickly move heavy loads without the need for slings, chains, or other traditional lifting devices. This speed not only enhances productivity but also reduces downtime in industrial settings.

2. Safety The magnetic lifting mechanism is designed to hold onto the load securely until the operator decides to release it. Unlike mechanical devices that can slip or fail under stress, magnetic lifters provide a more reliable solution, drastically reducing the risk of accidents and injuries.

magnetic lifter 500kg

3. Versatility The 500kg magnetic lifter is adaptable for various applications across sectors such as construction, manufacturing, and warehousing. Its ability to lift flat and smooth metal surfaces makes it invaluable in handling sheets, sections, and heavy machinery components.

4. Reduced Physical Strain Workers are often exposed to risks associated with manual lifting. The magnetic lifter removes much of the physical strain associated with moving heavy materials, contributing to better workplace ergonomics and lowering the incidence of lifting-related injuries.

5. Durability and Maintenance Magnetic lifters require minimal maintenance. The robust design typically withstands challenging work environments, thereby reducing maintenance costs and downtime.

Safety Features

While the magnetic lifter is generally a safe tool, it does incorporate several safety features to ensure the well-being of operators and the integrity of the load

- Safety Lock Mechanism This feature prevents accidental release, providing an added layer of security while lifting. - Load Testing Before lifting heavy loads, it is essential to perform load tests to ensure that the magnetic lifter is functioning correctly and within its rated capacity.

- Redundant Safety Margin Magnetic lifters are often designed with a lifting capacity that exceeds the maximum load to account for unforeseen circumstances or material inconsistencies.

Conclusion

The magnetic lifter 500kg serves as a vital asset in various industries that require reliable and efficient lifting solutions. With its combination of safety, efficiency, and ease of use, it stands out as a preferred choice among lifting equipment. As industries continue to evolve and strive for higher productivity levels while ensuring worker safety, the adoption of technologies like the magnetic lifter will only increase. Investing in such innovative lifting solutions not only enhances operational efficiency but also fosters a safer working environment for all employees. The future of heavy lifting is here, and it’s magnetic!

-

4000 lb Gantry Crane: Heavy-Duty, Adjustable Lifting SolutionsNewsAug.28,2025

-

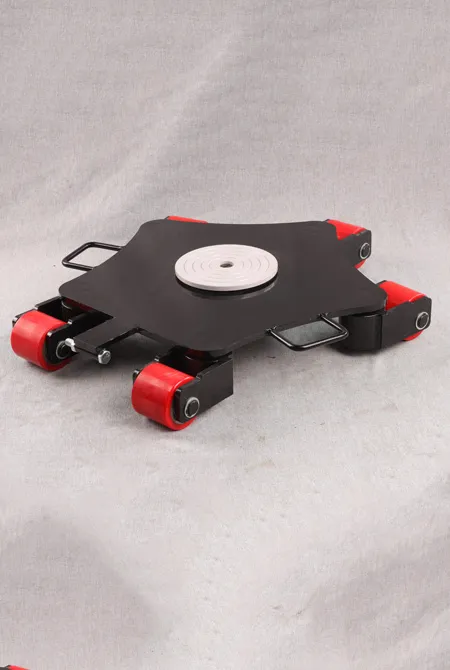

The Power of Trolley Cargo and Machinery Moving SolutionsNewsAug.22,2025

-

Exploring Magnetic Lifting Devices for Efficient Steel Plate HandlingNewsAug.22,2025

-

The Essential Guide to Portal CraneNewsAug.22,2025

-

Enhancing Efficiency in Permanent Magnetic LiftersNewsAug.22,2025

-

Heavy-Duty Machinery Movers and Material Handling SolutionsNewsAug.22,2025

-

The Comprehensive Guide to Adjustable Gantry CranesNewsAug.22,2025