rail mounted crane

The Advantages and Applications of Rail-Mounted Cranes

Rail-mounted cranes are vital pieces of equipment designed for specific applications where mobility, strength, and precision are of great importance. Unlike their wheeled counterparts, these cranes travel along fixed rails, making them highly efficient in environments such as ports, shipyards, and large factories. This article explores the advantages, applications, and future developments of rail-mounted cranes.

Advantages of Rail-Mounted Cranes

One of the primary benefits of rail-mounted cranes is their ability to lift heavy loads with great stability. The fixed rail system allows for a lower center of gravity, enhancing load control and safety during operations. Furthermore, these cranes can achieve higher lifting capacities compared to traditional wheeled cranes due to their robust design and solid support from the rail structure.

Another significant advantage is the operational efficiency that rail-mounted cranes deliver. Because they can travel along a predefined path, these cranes minimize the time required for loading and unloading materials. This feature is especially critical in high-demand environments such as shipping docks, where the quick turnover of cargo is essential. Rail-mounted cranes can also be programmed for automated operations, significantly reducing the need for manual labor and further enhancing productivity.

Additionally, rail-mounted cranes are highly versatile and can be customized to meet the specific needs of different industries. With options ranging from varying boom lengths, attachment accessories, and control systems, businesses can tailor these cranes to suit their specific operational requirements. This adaptability makes them suitable for a wide range of applications.

Applications of Rail-Mounted Cranes

Rail-mounted cranes find successful applications in various industries, primarily in heavy lifting and material handling. One prominent use is in shipping ports, where they are employed to transfer containers from ships to trucks or storage areas. Their stability and lifting power are crucial in ensuring safe and efficient operations in these bustling environments where timing is critical.

In manufacturing settings, rail-mounted cranes are often used on assembly lines for lifting heavy machinery or large components. They can streamline production processes by facilitating the movement of materials through different stages of production with ease. This can lead to significant improvements in workflow, reducing bottlenecks and downtime.

rail mounted crane

Another notable application is in construction projects where rail-mounted cranes are used for erecting large structures, such as bridges or high-rise buildings. They can move along tracks set up at the construction site, allowing for precise positioning and lifting of heavy materials. This feature is particularly valuable in complex construction projects requiring meticulous planning and execution.

Rail-mounted cranes are also prevalent in the mining and materials handling industries. They can be used to move bulk materials efficiently from one location to another, contributing to the efficiency of operations in these sectors.

Future Developments

As industries evolve, so too do the technologies associated with rail-mounted cranes. Future developments may include the integration of advanced automation and control systems, allowing these cranes to operate with minimal human intervention. This potential shift toward automated cranes can lead to improved safety and efficiency, providing an attractive solution for busy industries.

Furthermore, the trend toward sustainability is likely to influence the design and operation of rail-mounted cranes. Manufacturers are expected to focus on energy-efficient systems and materials that reduce the environmental impact associated with crane operations. Innovations such as electric rail-mounted cranes and those using alternative energy sources could become increasingly common.

In addition to technological advancements, the design of rail-mounted cranes is also anticipated to evolve, focusing on enhancing ergonomics and user-friendliness. Improvements in interface design and control technology can facilitate easier operation, making these cranes more accessible to a broader range of operators.

Conclusion

Rail-mounted cranes are indispensable assets in many industrial settings, offering distinctive advantages related to strength, stability, and efficiency. As their use expands across various sectors, so too does the potential for innovation and improvement. By embracing technology and sustainable practices, the future of rail-mounted cranes looks promising, ensuring they continue to meet the demands of modern-day industries effectively. Whether in ports, construction sites, or manufacturing plants, rail-mounted cranes are set to remain at the forefront of heavy lifting solutions for years to come.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

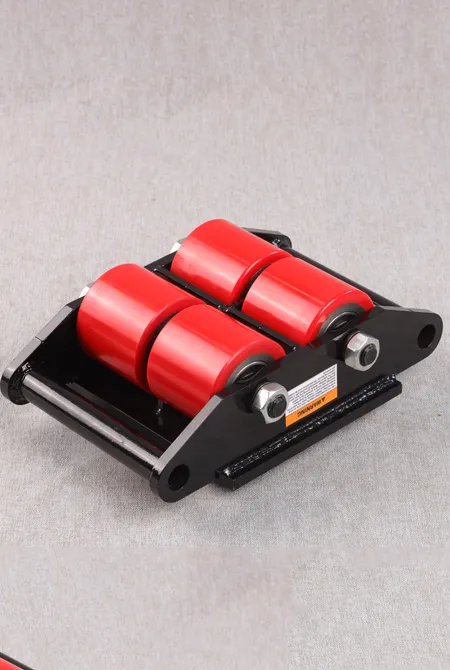

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025