tri adjustable gantry crane

The Tri-Adjustable Gantry Crane Innovations in Material Handling

The tri-adjustable gantry crane represents a significant advancement in material handling technologies, designed to enhance efficiency and versatility in various industrial applications. As businesses continue to seek solutions that streamline operations, improve safety, and increase productivity, the tri-adjustable gantry crane stands out for its customizable features and robust construction.

Design and Features

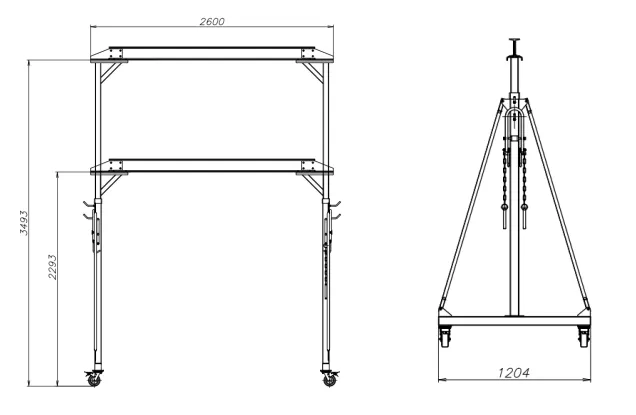

The hallmark of a tri-adjustable gantry crane is its unique capability to adjust in three different planes height, width, and span. This versatility allows operators to tailor the crane to specific lifting tasks, accommodating a variety of load sizes and types. The crane typically consists of an adjustable A-frame structure built from high-strength steel, ensuring it can handle heavy loads while maintaining stability and safety standards.

1. Height Adjustment The ability to modify the height of the crane is particularly beneficial when dealing with different load dimensions or working in spaces with varying ceiling heights. Operators can easily reposition the crane's legs to achieve optimal lifting height, making it ideal for warehouses and manufacturing facilities.

2. Width Adjustment Width adjustments enable the crane to accommodate loads of varying widths. This feature is invaluable when transporting items through narrow aisles or around tight corners, minimizing the risk of damage to the load or the surrounding infrastructure.

3. Span Adjustment By extending or retracting the span, users can lift loads of different lengths without the need for specialized equipment. This adjustability eliminates the need for multiple cranes for different tasks, saving both time and resources.

Applications

Tri-adjustable gantry cranes are utilized in various sectors, including manufacturing, construction, shipping, and maintenance facilities

. Their adaptability makes them suitable for different applications, such astri adjustable gantry crane

- Warehousing and Distribution In environments where materials need to be stored and moved quickly, tri-adjustable gantry cranes streamline the process, allowing for efficient loading and unloading of goods.

- Manufacturing In factories, these cranes can be used to lift heavy machinery and components, facilitating quick assembly and maintenance. Their adjustability ensures that even in busy production environments, they can be utilized effectively without requiring extensive setup time.

- Construction Sites The flexibility of these cranes makes them a valuable asset on construction sites, where they can lift and move materials across varying terrains and elevations.

Safety and Efficiency

Safety is paramount in any industrial setting, and the tri-adjustable gantry crane is designed with this in mind. Its robust construction and low center of gravity provide stability, while adjustable features contribute to safer load handling. Additionally, the crane typically includes safety mechanisms such as limit switches and overload protection, further minimizing the risk of accidents.

From an efficiency standpoint, the ability to quickly adjust height, width, and span allows for swift transitions between tasks. This adaptability can significantly reduce downtime, leading to increased productivity. Operators can spend less time adjusting equipment and more time focusing on their core functions.

Conclusion

The tri-adjustable gantry crane represents a remarkable innovation in material handling, combining versatility, safety, and efficiency. Its design allows for significant customization, enabling businesses to meet a wide range of operational needs without investing in several specialized cranes. As industries continue to evolve and adapt to ever-changing demands, the adoption of equipment like the tri-adjustable gantry crane will be instrumental in ensuring competitive advantage and operational effectiveness. As companies strive to optimize their workflows and reduce operational costs, the tri-adjustable gantry crane is poised to play a pivotal role in the future of industrial material handling.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025