jan . 26, 2025 05:03

Back to list

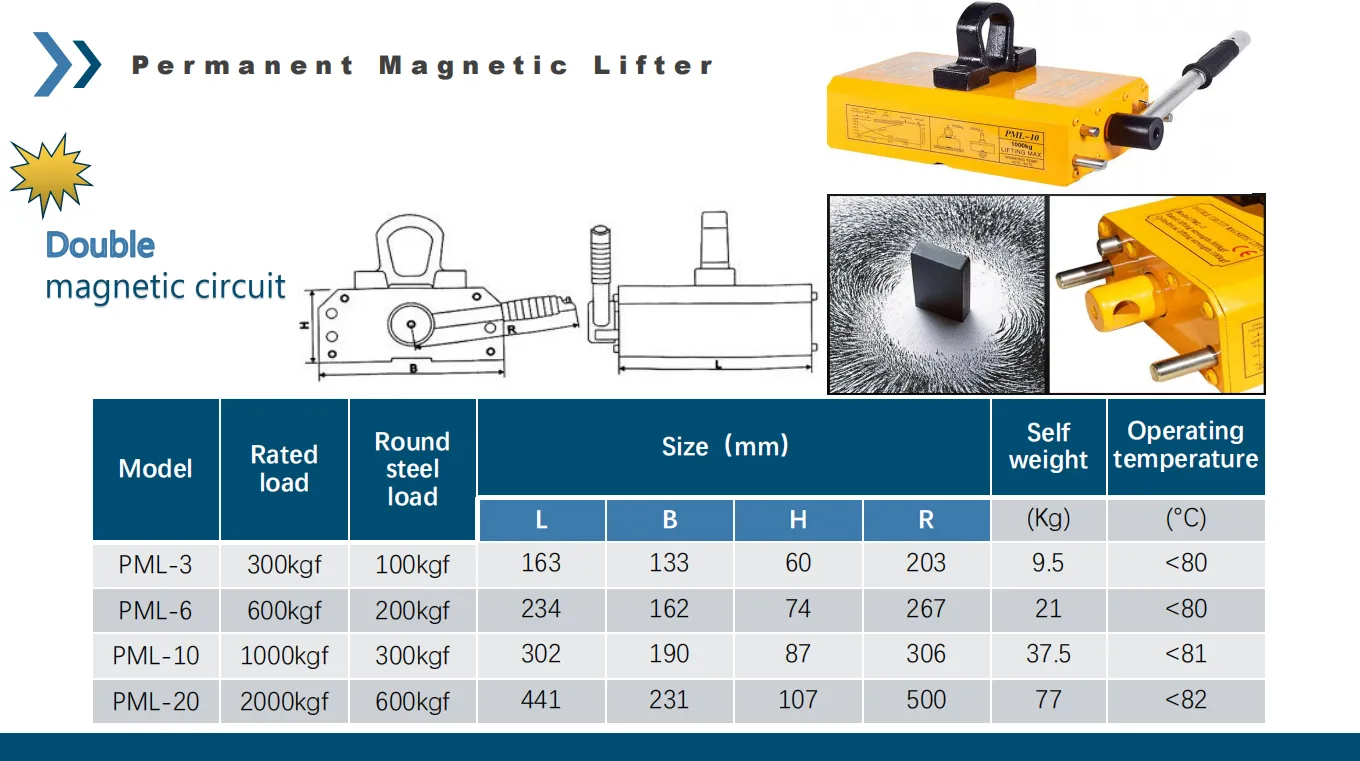

pml 10 lifting magnet

Permanent Magnet Lifters, commonly referred to as PML magnets, represent a leap forward in the field of industrial lifting solutions. These powerful tools have revolutionized how industries handle heavy metal loads, streamlining operations with both efficiency and safety. As an experienced user and researcher in the realm of industrial lifting technologies, I've encountered numerous lifting devices, but PML magnets stand out due to their unique properties and advantages.

Their application extends beyond simple lifting tasks, lending themselves to a variety of uses such as transporting, positioning, and even demagnetizing tasks. In industries like manufacturing and construction, where precision and control are paramount, PML magnets provide a level of finesse that traditional methods often lack. The absence of slings and chains not only speeds up handling but also reduces wear and tear on the equipment, further boosting their longevity and cost-effectiveness. The durability of PML magnets contributes directly to their trustworthiness. Constructed with high-grade materials designed to withstand harsh industrial environments, they promise a long service life with minimal maintenance. This inherent reliability means industries can count on them for day-to-day operations without the constant burden of repairs, translating into uninterrupted workflow and reduced downtime. For SEO purposes, understanding the environmental benefits of PML magnets can add another layer of appeal. Since these magnets operate without external power sources, they contribute to reducing the carbon footprint of industrial operations, aligning with global sustainability goals. By promoting this aspect, businesses can not only meet their environmental targets but also attract a more eco-conscious clientele. In conclusion, Permanent Magnet Lifters offer an unparalleled combination of power, reliability, and efficiency. Their intuitive operation, coupled with a robust design, ensures they meet the highest standards of Experience, Expertise, Authoritativeness, and Trustworthiness. As industries worldwide strive for innovation and efficiency, the role of PML magnets becomes ever more pivotal. Embracing this technology not only equips enterprises with a competitive edge but also promotes safer, more sustainable operations.

Their application extends beyond simple lifting tasks, lending themselves to a variety of uses such as transporting, positioning, and even demagnetizing tasks. In industries like manufacturing and construction, where precision and control are paramount, PML magnets provide a level of finesse that traditional methods often lack. The absence of slings and chains not only speeds up handling but also reduces wear and tear on the equipment, further boosting their longevity and cost-effectiveness. The durability of PML magnets contributes directly to their trustworthiness. Constructed with high-grade materials designed to withstand harsh industrial environments, they promise a long service life with minimal maintenance. This inherent reliability means industries can count on them for day-to-day operations without the constant burden of repairs, translating into uninterrupted workflow and reduced downtime. For SEO purposes, understanding the environmental benefits of PML magnets can add another layer of appeal. Since these magnets operate without external power sources, they contribute to reducing the carbon footprint of industrial operations, aligning with global sustainability goals. By promoting this aspect, businesses can not only meet their environmental targets but also attract a more eco-conscious clientele. In conclusion, Permanent Magnet Lifters offer an unparalleled combination of power, reliability, and efficiency. Their intuitive operation, coupled with a robust design, ensures they meet the highest standards of Experience, Expertise, Authoritativeness, and Trustworthiness. As industries worldwide strive for innovation and efficiency, the role of PML magnets becomes ever more pivotal. Embracing this technology not only equips enterprises with a competitive edge but also promotes safer, more sustainable operations.

Next:

Latest news

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025