Feb . 13, 2025 21:43

Back to list

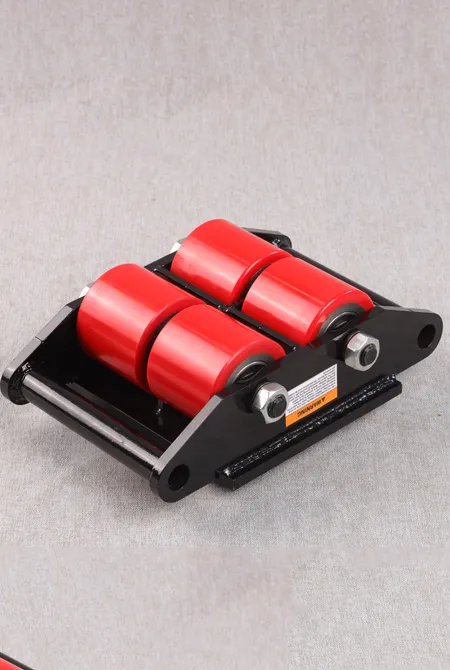

heavy equipment rollers

Heavy equipment rollers play an essential role in a myriad of construction and infrastructure projects. These robust machines are designed to ensure the stability and smoothness of surfaces, whether paving roads or preparing large-scale construction foundations. As an integral part of the construction industry, understanding the nuances of heavy equipment rollers can significantly enhance project outcomes. Here, we delve into the critical aspects to bolster your comprehension and application of these mighty machines.

Furthermore, manufacturers of heavy equipment rollers are pioneers in technological evolution, continually advancing roller capabilities through innovative designs and features. For instance, modern rollers come equipped with operator-friendly features like ergonomic controls, state-of-the-art safety mechanisms, and even GPS for precision tracking. Some models boast advanced telematics systems that offer real-time data analysis, thus enabling better workforce management and project efficiency. Real-world Experience Contractors and construction firms share a myriad of success stories that hinge on selecting the correct roller for their projects. In urban development projects, precision, and timely execution are critical. Contractors often emphasize that using double drum vibratory rollers can speed up operations while maintaining exceptional quality standards, leading to reduced project timelines and cost efficiencies. For rural infrastructure involving local road networks, pneumatic tired rollers have been cited as instrumental in achieving optimal surface evenness and compactness despite irregular terrain challenges. Thus, field experience suggests that investment in suitable heavy equipment rollers amasses long-term dividends in resilience and durability of the infrastructure constructed. Trustworthiness The credibility of manufacturers and suppliers in the heavy equipment industry is paramount. Establishing trust involves rigorous testing and adherence to international and local standards. Certified dealers and manufacturers assure their products are durable, safe, and efficient—criteria critical for rollers designed to withstand rigorous operational environments. Furthermore, ongoing maintenance and service support is another layer of trustworthiness provided by reputed manufacturers. This includes comprehensive maintenance agreements, accessible parts inventory, and timely service, ensuring that projects face minimal downtimes and avoid cost overruns due to equipment failures. In conclusion, heavy equipment rollers are indispensable in achieving flawless construction outcomes. From enhancing soil compaction through sophisticated technologies to upholding project integrity through dependable service support, rollers are the linchpins of the modern construction industry. By aligning your project needs with the right type of heavy equipment roller, substantial improvements in efficiency, cost-effectiveness, and quality are assured—a testament to both the engineering excellence behind these machines and the knowledgeable professionals that recommend and operate them.

Furthermore, manufacturers of heavy equipment rollers are pioneers in technological evolution, continually advancing roller capabilities through innovative designs and features. For instance, modern rollers come equipped with operator-friendly features like ergonomic controls, state-of-the-art safety mechanisms, and even GPS for precision tracking. Some models boast advanced telematics systems that offer real-time data analysis, thus enabling better workforce management and project efficiency. Real-world Experience Contractors and construction firms share a myriad of success stories that hinge on selecting the correct roller for their projects. In urban development projects, precision, and timely execution are critical. Contractors often emphasize that using double drum vibratory rollers can speed up operations while maintaining exceptional quality standards, leading to reduced project timelines and cost efficiencies. For rural infrastructure involving local road networks, pneumatic tired rollers have been cited as instrumental in achieving optimal surface evenness and compactness despite irregular terrain challenges. Thus, field experience suggests that investment in suitable heavy equipment rollers amasses long-term dividends in resilience and durability of the infrastructure constructed. Trustworthiness The credibility of manufacturers and suppliers in the heavy equipment industry is paramount. Establishing trust involves rigorous testing and adherence to international and local standards. Certified dealers and manufacturers assure their products are durable, safe, and efficient—criteria critical for rollers designed to withstand rigorous operational environments. Furthermore, ongoing maintenance and service support is another layer of trustworthiness provided by reputed manufacturers. This includes comprehensive maintenance agreements, accessible parts inventory, and timely service, ensuring that projects face minimal downtimes and avoid cost overruns due to equipment failures. In conclusion, heavy equipment rollers are indispensable in achieving flawless construction outcomes. From enhancing soil compaction through sophisticated technologies to upholding project integrity through dependable service support, rollers are the linchpins of the modern construction industry. By aligning your project needs with the right type of heavy equipment roller, substantial improvements in efficiency, cost-effectiveness, and quality are assured—a testament to both the engineering excellence behind these machines and the knowledgeable professionals that recommend and operate them.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025