machinery mover

The Essential Role of Machinery Movers in Industry

In the contemporary industrial landscape, machinery movers play a crucial role in ensuring the efficient operation and relocation of heavy equipment. These specialized professionals not only aid in the transportation of machinery but also ensure that these substantial assets are handled with utmost care to avoid damage and ensure safety in the workplace.

Machinery movers are experts in handling large and often cumbersome equipment that ranges from industrial machinery to construction equipment. Their skill set includes a deep understanding of mechanical systems, rigging techniques, and the use of various tools and equipment designed specifically for moving heavy loads. This expertise is vital, as improper handling of machinery can lead to severe accidents, costly damages, and prolonged downtimes that can affect an entire operational cycle.

One of the primary responsibilities of a machinery mover is to evaluate the logistics involved in transporting equipment. This assessment includes understanding the weight, size, and fragility of the machinery, as well as the environment in which it is to be moved. Machinery movers must devise a plan that entails ensuring that all safety protocols are followed, minimizing risks not only to the equipment but also to the personnel involved in the move.

Safety is paramount in the operation of machinery movers

. They are trained in using personal protective equipment (PPE) and adhere to strict safety regulations. This training helps them identify potential hazards on a job site, such as unstable ground, overhead obstructions, or the presence of corded power lines. Furthermore, they often work in teams, employing communication strategies and coordination to ensure all movements are executed smoothly and safely.machinery mover

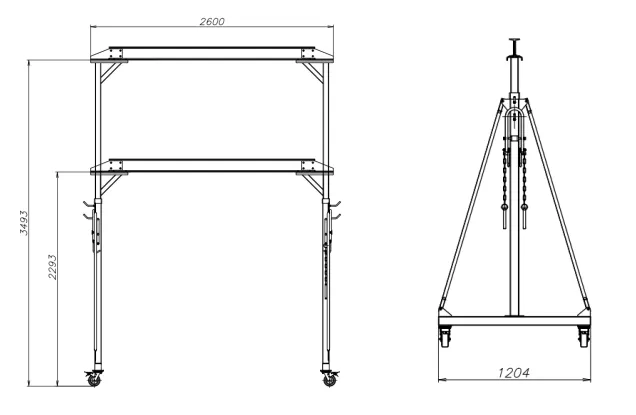

Another critical aspect of the machinery moving business is the use of specialized equipment. Machinery movers utilize dollies, forklifts, cranes, and rigging equipment to facilitate the movement of heavy items. Cranes, for example, are often employed to lift machinery from locations where a direct approach is impractical. The precision required in operating such equipment necessitates extensive training and practice, highlighting the skill level of machinery movers in comparison to general labor.

In addition to moving equipment within facilities, machinery movers also play a significant role in relocating entire manufacturing plants or refitting production lines. Companies often expand or downsize operations, requiring the shifting of machinery to new locations. In these cases, machinery movers display their adaptability by managing logistics that can include long-haul transportation, navigating regulatory requirements, and sometimes even disassembling and reassembling machinery.

The economic impact of machinery movers is significant. By ensuring the efficient relocation and setup of machinery, businesses can minimize downtime and maintain productivity levels. This is especially critical in industries where time is money, such as manufacturing and construction. A delay in production or equipment malfunction can lead to substantial financial losses, making the work of machinery movers invaluable.

In conclusion, machinery movers are a vital component of industrial operations. They combine technical skills, safety awareness, and logistical planning to facilitate the efficient handling of heavy machinery. As industries continue to evolve and grow, the demand for skilled machinery movers will undoubtedly increase, underscoring their critical importance in the modern economy. By investing in professional machinery moving services, companies can safeguard their investments and ensure continuous operational efficiency.

-

The Power of Trolley Cargo and Machinery Moving SolutionsNewsAug.22,2025

-

Exploring Magnetic Lifting Devices for Efficient Steel Plate HandlingNewsAug.22,2025

-

The Essential Guide to Portal CraneNewsAug.22,2025

-

Enhancing Efficiency in Permanent Magnetic LiftersNewsAug.22,2025

-

Heavy-Duty Machinery Movers and Material Handling SolutionsNewsAug.22,2025

-

The Comprehensive Guide to Adjustable Gantry CranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025