gantry crane beam

Understanding the Importance of Gantry Crane Beams

Gantry cranes are vital pieces of equipment in various industrial sectors, known for their ability to lift and move heavy loads efficiently. At the heart of these cranes lies the gantry crane beam, a crucial structural component that supports the crane’s operations. This article explores the significance of gantry crane beams, their types, design considerations, and applications across different industries.

What is a Gantry Crane Beam?

A gantry crane beam is typically a large, horizontal beam supported by vertical legs that allow the crane to move freely along a designated track. This structure is designed to bear heavy loads, ranging from several tons to upwards of 100 tons or more, depending on the application. The efficiency of a gantry crane is largely determined by the load capacity and rigidity of the beam, as it must withstand stresses during loading and unloading operations.

Types of Gantry Crane Beams

Gantry crane beams come in various types, each designed for specific applications. The main types include

1. Box Beams These are hollow, rectangular beams that offer high strength-to-weight ratios. Their enclosed shape makes them economical to fabricate while providing impressive rigidity and stability.

2. I-Beams The I-beam, shaped like the letter “I,” is commonly used in construction. It provides excellent load distribution and is often used in heavy-duty applications, allowing for longer span lengths without compromising structural integrity.

3. T-Beams These are similar to I-beams but with a flange that is wider on one side, which helps distribute loads effectively. T-beams are frequently used in various types of overhead lifting systems.

4. Lattice Beams Constructed of several smaller components, lattice beams are lightweight yet sturdy. They are often used in applications requiring high flexibility and reduced weight, making them ideal for portable gantry cranes.

Design Considerations

Designing a gantry crane beam requires careful consideration of several key factors

- Load Capacity The maximum load the beam is required to support is perhaps the most critical factor. Engineers need to ensure that the selected beam can handle both static and dynamic loads without deforming or breaking.

gantry crane beam

- Material Selection Common materials for gantry crane beams include steel and aluminum. Steel is preferred for its high strength and durability, while aluminum is chosen for lightweight applications where portability is essential.

- Span Length The distance between supports greatly influences beam design. Longer spans require more robust constructions, potentially leading to increased material costs and weight.

- Environmental Conditions Factors such as temperature, humidity, and exposure to chemicals must also be considered, especially in outdoor or harsh environments. Corrosion-resistant coatings or materials may be necessary.

Applications of Gantry Crane Beams

Gantry crane beams are utilized across a wide range of industries

1. Manufacturing In manufacturing plants, gantry cranes facilitate the handling of heavy components and assemblies, significantly improving production efficiency.

2. Construction They are commonly used on construction sites to lift and move materials, such as steel beams and concrete blocks, across varying elevations.

3. Shipping and Port Operations Gantry cranes are essential in shipping yards for loading and unloading cargo from containers. Their ability to maneuver over large shipping vessels enhances productivity and safety.

4. Maintenance and Repair Gantry cranes are often employed in workshops for equipment maintenance and repairs, allowing workers to lift and position heavy machinery with ease.

5. Warehousing In warehouses, gantry cranes optimize space utilization by enabling vertical stacking of goods that would otherwise be difficult to manage.

Conclusion

Gantry crane beams are crucial in the efficient handling of heavy loads across multiple industries. Understanding their types, design considerations, and applications can help businesses optimize operations and ensure safety in their lifting tasks. As technology advances, the design and materials of gantry crane beams continue to evolve, enhancing their capabilities and applications, making them indispensable tools in modern industrial operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

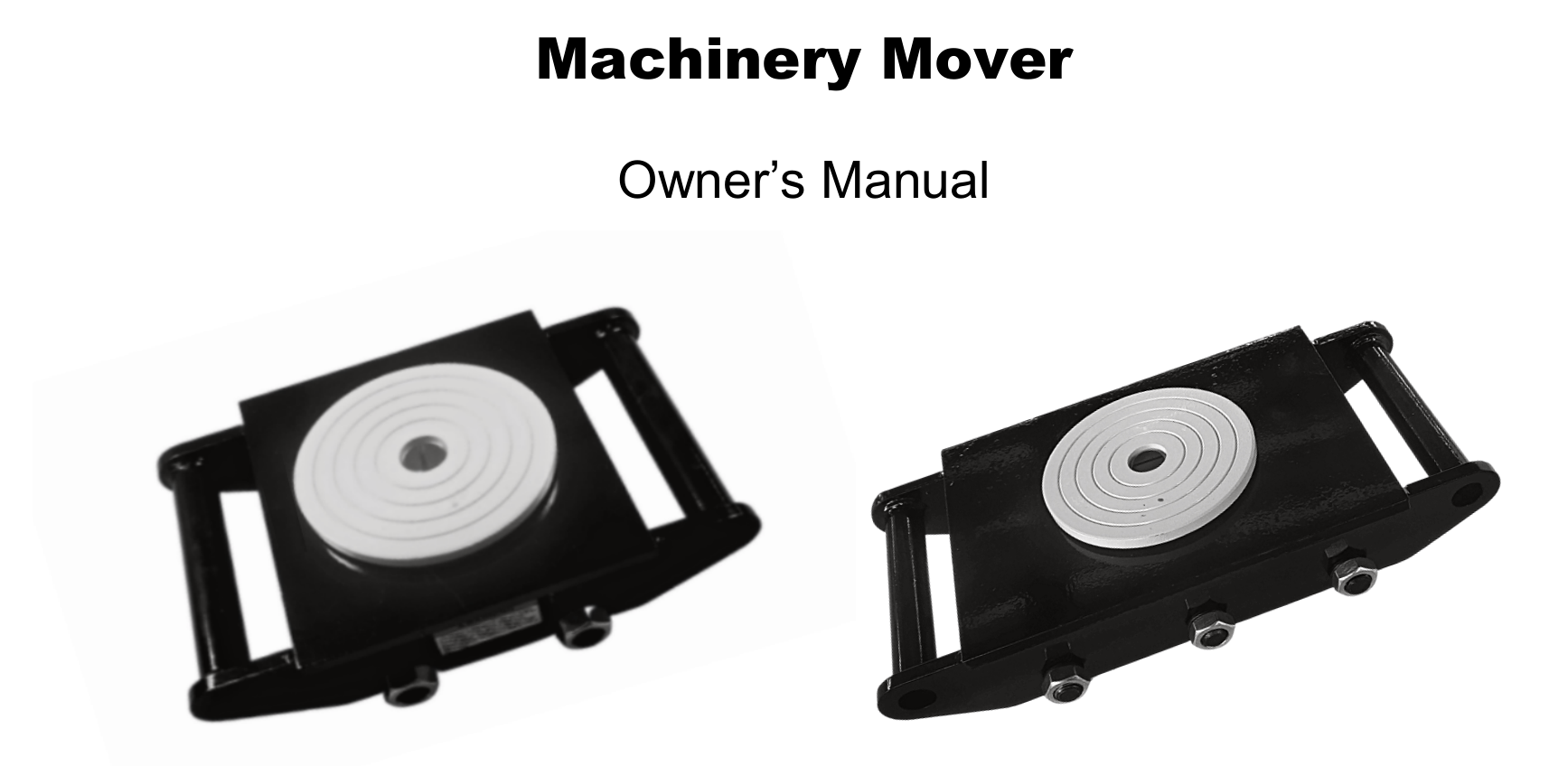

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025