Feb . 14, 2025 06:26

Back to list

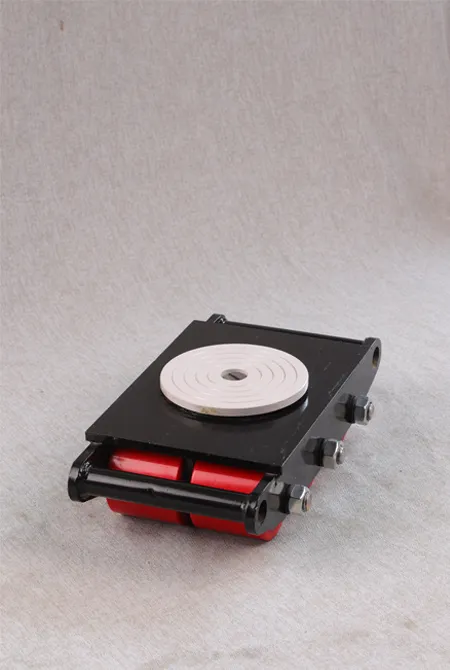

roller heavy machine

Roller heavy machines, known for their pivotal role in construction and road-building projects, have evolved significantly over the decades. This article delves into the nuances of these machines, highlighting why they are indispensable, how to choose the right one for your needs, and exploring their immense contribution to infrastructural development.

From an expertise viewpoint, understanding how to maintain and operate these machines significantly impacts their performance and lifecycle. Regular inspections, timely lubrication, and checks for wear and tear are imperative. Operators should also be adequately trained to leverage the machine's features efficiently—mistakes in operations can lead to uneven surfaces or structural issues that might compromise a project's integrity. Government guidelines, which dictate compaction standards, further underline the authoritativeness of roller machines in construction. Compliance with these regulations not only enhances project approvals but also underpins the machines' reliability and trustworthiness in achieving precise compaction levels. The machines should be vetted for their ability to meet or exceed these regulatory requirements, ensuring safety and quality are never compromised. Industry trends suggest an increase in the adoption of technologically advanced roller heavy machines, with intelligent compaction systems that use GPS and other sensory data for enhancing precision in real-time. Such advancements reinforce the machines' role in optimizing construction efficiencies and ensuring consistent quality outputs. In conclusion, roller heavy machines are indeed the unsung heroes of construction—facilitating the realization of infrastructural ambitions globally. From selecting the right type to mastering its operation and maintenance, proficiency in using these machines ensures that they not only meet but often exceed project expectations. Their contribution to the construction domain is invaluable, underscoring a blend of technological prowess and engineering excellence, which has become pivotal in modern development narratives.

From an expertise viewpoint, understanding how to maintain and operate these machines significantly impacts their performance and lifecycle. Regular inspections, timely lubrication, and checks for wear and tear are imperative. Operators should also be adequately trained to leverage the machine's features efficiently—mistakes in operations can lead to uneven surfaces or structural issues that might compromise a project's integrity. Government guidelines, which dictate compaction standards, further underline the authoritativeness of roller machines in construction. Compliance with these regulations not only enhances project approvals but also underpins the machines' reliability and trustworthiness in achieving precise compaction levels. The machines should be vetted for their ability to meet or exceed these regulatory requirements, ensuring safety and quality are never compromised. Industry trends suggest an increase in the adoption of technologically advanced roller heavy machines, with intelligent compaction systems that use GPS and other sensory data for enhancing precision in real-time. Such advancements reinforce the machines' role in optimizing construction efficiencies and ensuring consistent quality outputs. In conclusion, roller heavy machines are indeed the unsung heroes of construction—facilitating the realization of infrastructural ambitions globally. From selecting the right type to mastering its operation and maintenance, proficiency in using these machines ensures that they not only meet but often exceed project expectations. Their contribution to the construction domain is invaluable, underscoring a blend of technological prowess and engineering excellence, which has become pivotal in modern development narratives.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025