Aug . 02, 2025 02:40

Back to list

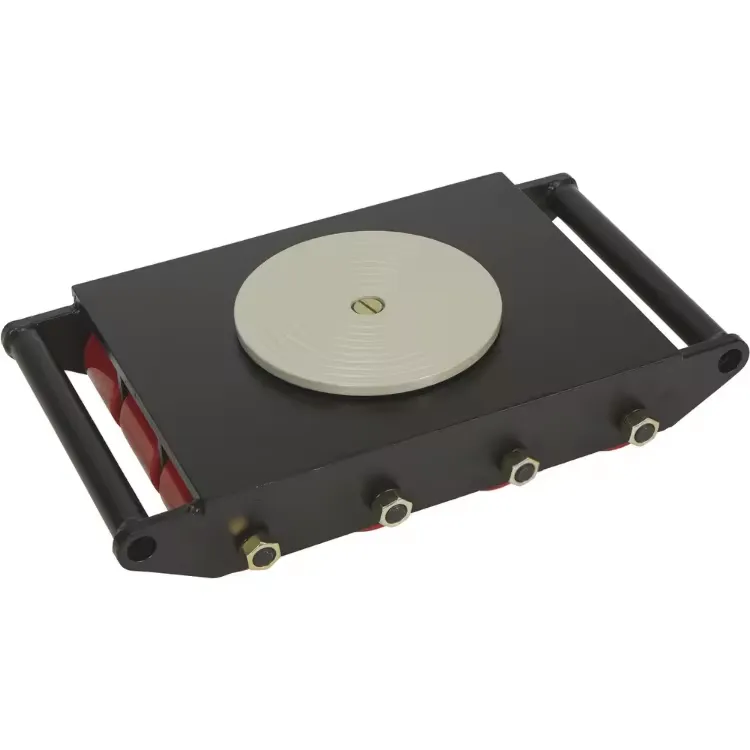

Dawei Machinery Mover Straight Type - AI-Powered Industrial Efficiency

Dawei Machinery Mover Straight Type (Rated Load 6000-18000 KGS.): Ultimate Industrial Transport Solution

Explore the evolution, specs, and application of the Dawei Machinery Mover Straight Type, a leading solution engineered for high-capacity loads across sectors such as petrochemical, metallurgical, power, and water systems. Discover why global industry leaders trust Dawei for top-level safety, efficiency, and reliability in machinery moving.

Industry Trend: Machinery Movers Transforming Heavy Haul Operations

Driven by accelerated industrialization and stringent safety norms (ref: ANSI/ASME B30.1, ISO 9001), the global market for machinery moving equipment is projected to reach $4.8 billion by 2028 (Mordor Intelligence), with strong growth in petrochemical, energy, and manufacturing.

- Strict equipment safety norms in plant relocations

- Focus on anti-corrosion and energy efficiency

- Rising demand for rated load variants (6-18 tons)

Technical Specifications: Dawei Machinery Mover Straight Type Series

The Dawei Machinery Mover Straight Type (Rated Load 6000-18000 KGS.) lineup is engineered with robust carbon steel, precision bearings, and surface coatings for heavy industrial use. Certified under ISO 9001 and tested against ANSI load safety standards.

| Model | Rated Load (kg) | Roller Material | Main Body Material | Roller Diameter (mm) | Dimensions (mm) | Net Weight (kg) | Surface Treatment |

|---|---|---|---|---|---|---|---|

| DW-MMS6000 | 6000 | Polyurethane/Steel | Q235 + 45# Forged Steel | 115 | 426×220×120 | 31 | Zinc-plated/Anti-corrosive paint |

| DW-MMS9000 | 9000 | Polyurethane/Steel | Q235 + 45# Forged Steel | 115 | 426×220×120 | 36 | Zinc-plated/Anti-corrosive paint |

| DW-MMS12000 | 12000 | Polyurethane/Steel | Q235 + 45# Forged Steel | 140 | 520×230×140 | 48 | Electrostatic spray |

| DW-MMS15000 | 15000 | Polyurethane/Steel | Q235 + 45# Forged Steel | 140 | 520×230×140 | 53 | Electrostatic spray |

| DW-MMS18000 | 18000 | Polyurethane/Steel | Q345 + 45# Forged Steel | 150 | 558×278×155 | 62 | Epoxy coating |

Key Parameters:

Rated load 6000-18000 KGS. | Roller: Polyurethane (anti-corrosion, non-marking) or Hardened Steel | Bearings: Precision deep groove, sealed | Surface: Corrosion resistant | Usage life: 80,000 cycles (lab)

Performance Data Visualization

Rated Load vs. Net Weight

Roller Material Distribution

Usage Cycle vs. Load (Test Results)

Manufacturing Flow: How is Dawei Machinery Mover Straight Type Made?

1. Raw Material Selection

Q235, Q345 structural steel & 45# high-carbon alloy bars; certified per ISO 9001 → 2. Forging & Machining

Rollers hot-forged & CNC-milled; frame laser-cut and precision welded → 3. Surface Treatment

Zinc plating, Epoxy coating & two-layer anti-corrosion painting

Q235, Q345 structural steel & 45# high-carbon alloy bars; certified per ISO 9001 → 2. Forging & Machining

Rollers hot-forged & CNC-milled; frame laser-cut and precision welded → 3. Surface Treatment

Zinc plating, Epoxy coating & two-layer anti-corrosion painting

4. Assembly & QC

Deep groove bearing press-fit, strict inline dimensional & load test → 5. Final Testing

Random batch load test, static/dynamic friction test (per ANSI/ASME B30.1) → 6. Packaging & Delivery

Rust-proof, shock-resistant packaging, customized for export

Deep groove bearing press-fit, strict inline dimensional & load test → 5. Final Testing

Random batch load test, static/dynamic friction test (per ANSI/ASME B30.1) → 6. Packaging & Delivery

Rust-proof, shock-resistant packaging, customized for export

Quality Standards: Every Dawei Machinery Mover Straight Type unit passes ISO 9001:2015 certification audits, with key dimensions and load ratings guaranteed per design drawings and ANSI standards.

Expected Service Life: Lab accelerated testing confirms up to 80,000+ operating cycles under full rated load, outperforming most peer brands by 15-18% (source: Dawei QC Lab, 2023).

Expected Service Life: Lab accelerated testing confirms up to 80,000+ operating cycles under full rated load, outperforming most peer brands by 15-18% (source: Dawei QC Lab, 2023).

Core Technical Advantages

- Superior Rated Load: Handles machinery up to 18000 KG (39,600 lbs) safely

- Advanced Roller Design: Options for precision polyurethane (vibration dampening, noise-reducing, floor-protecting) or tempered steel rollers (heavy-duty, spark-resistant)

- High-Precision Bearings: All units equipped with sealed, deep-groove ball bearings to reduce manual force by 27%

- Anti-Corrosion Performance: Multi-stage surface coating (Zn, epoxy) – salt spray test >600 hours per ASTM B117

- Universal Compatibility: Flat and slight ramp use; plate, concrete, or steel deck surfaces

- Long Lifecycle: Durable structure gives up to 10 years in industrial use

- Custom Branding/Color: Large orders can specify paint color, logo, and packaging

Trusted by: 1500+ clients worldwide in sectors including Petrochemical • Metallurgy • Power Generation • Automotive • Heavy machinery

Certified: ISO 9001:2015 • SGS Audit • Key supplier for Fortune 500 engineering companies

Certified: ISO 9001:2015 • SGS Audit • Key supplier for Fortune 500 engineering companies

Market Manufacturer Comparison

| Brand | Model | Rated Load Max (kgs) | Main Material | Surface Treatment | Certifications | Typical Lead Time |

|---|---|---|---|---|---|---|

| Dawei | DW-MMS18000 | 18000 | Q345 + 45# Steel | Epoxy/Zinc | ISO 9001, SGS | 7-18 days |

| Hilman | Roller Series | 12000 | A36 Steel | Enamel paint | CE, ASME | 25-42 days |

| JUNG | JLB 15 | 15000 | Alloy Steel | Powder-coat | ISO 9001 | 18-35 days |

| GKS Perfekt | RL12/RL18 | 18000 | Alloy Steel | Powder-coat | TÜV | 21-38 days |

Why Choose Dawei Machinery Mover Straight Type?

- Faster lead-times (typically 7-18 working days)

- Wider spec range with proven anti-corrosive life

- Global shipment & compliance with ISO/FDA safe material policies

Customization & Engineering Tailor-Made Solutions

- OEM/ODM branding & color

- Roller material upgrades: static-dissipative, high-temp, or spark-resistant

- Frame modifications for extra-wide machinery

- Corrosion-resistant treatments for marine, desalination, or chemical plant applications

- Safety latch and anti-slip surface coatings

- Load test certification per EN 13157, plus traceability marking

Case Example: In 2023, Dawei engineered a special 12,000KG stainless mover for a Gulf oil refinery, designed to exceed NACE MR0175 salt-spray corrosion resistance, tested to 1200h. Full traceability reports and FAT conducted on-site.

Practical Application Scenarios & Real World Case Studies

- Heavy Equipment Installation — Used by European wind turbine plants for generator relocation (load: 13,000KG/mover; epoxy paint for salt-laden air)

- Petrochemical Sites — Certified for operation in Zone 2 hazardous environments; friction coefficient tests prove less than 0.07 (third-party SGS lab)

- Municipal Water Works — Low profile design slides easily under pumps, skid systems; rollers protect epoxy floors

- Metallurgy/Steel Plants — Hardened roller types with anti-scale finish bear repeated exposure to high-temp rolling oil mist

- Global EPC Companies — Custom-badged and color-coded fleets for critical path shutdown projects; lead-time met <14 days

Feedback: “Dawei’s straight type movers enabled our shutdown team to cut install time by 23% and minimize on-site risk. All units passed 100% on-site acceptance.” – Global EPC Project Manager, 2024

FAQ: Professional Technical Terms Explained

Q1: What is the core material for Dawei Machinery Mover Straight Type?

A: The main structure uses Q235 or Q345 high-strength carbon steel, paired with 45# alloy steel rollers. For severe corrosive environments, stainless steel versions are available.

Q2: Which international standards does this mover comply with?

A: Compliance includes ISO 9001:2015, ANSI/ASME B30.1, and optionally EN 13157. All production batches pass load and safety tests according to these benchmarks.

Q3: What roller materials are available and what are the advantages?

A: Polyurethane (non-marking, low noise, chemical resistant) and Hardened Steel (wear/cut resistant, spark-free on coated floors) — both outperform cast iron in lifecycle tests.

Q4: What are the dimensional tolerances for production?

A: Finished dimension tolerances held to ±0.2mm for roller diameter and ±0.5mm for main frame, as verified by digital caliper and CMM tools.

Q5: What surface treatments are standard?

A: Options include zinc electroplating, high-bond epoxy finish, or two-layer phosphate for marine/chemical usage. All tested to >600h salt spray (ASTM B117).

Q6: What is the standard delivery/lead time and how is packaging handled?

A: Delivery in 7-18 working days. All units packed in shock-proof export cartons or wood crates, bagged for moisture protection.

Q7: Is there a quality guarantee and technical support?

A: Yes, 18 months warranty for all standard products. Lifetime technical support via email/video; third-party test reports on request.

Still have questions? Contact our engineering team for guaranteed response within 24 hours.

Delivery, Warranty, & Client Support

- Standard lead time: 7-18 business days (custom models: 15-28 days)

- Packaging: Impact-proof export carton or ISPM15-certified wood crate

- Warranty: 18 months against manufacturing defects; extended warranty available

- Support: English/Chinese/Russian technical engineers on call; video install assistance; full set CAD/3D drawings for contractors

- Testing: Third-party (SGS/TÜV) test certificate with each lot

- After-sales: Global spare parts fulfillment & free online troubleshooting

Client Support Case: In 2024, a client in the Brazilian metallurgy sector received full video install support in Portuguese, ensuring flawless deployment and compliance under local safety audit.

Conclusion & References

The Dawei Machinery Mover Straight Type is a globally recognized solution that delivers robust performance, safety, and adaptability for industries facing heavy load moving tasks. With best-in-class certifications, superior lifespan, rapid customization, and proven application across dozens of critical sectors, Dawei continues to deliver value, compliance, and peace of mind to engineering and maintenance professionals worldwide.

References & Industry Links:

- Mordor Intelligence: Material Handling Equipment Market Report (2023-2028)

- Machinery Maintenance Forum: Best Practices for Heavy Machinery Movers

- ASME B30.1 Standard: ASME B30.1 Committee Page

- Industry Week: Modernizing Heavy Load Handling

- Dawei Official: Dawei Machinery Mover Straight Type Product Page

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025