Heavy-Duty Machine Moving Dollies Industrial Equipment Transport Solutions

- Understanding the Role of Heavy Machine Dollies in Industrial Operations

- Technical Advantages: What Sets Modern Machine Moving Dollies Apart

- Manufacturer Comparison: Performance Metrics Across Leading Brands

- Custom Solutions for Heavy Machinery Transportation Challenges

- Case Studies: Real-World Applications of Heavy Machinery Moving Dollies

- Safety Standards and Maintenance Best Practices

- Future Trends in Heavy Machine Dollies Innovation

(heavy machine dollies)

Understanding the Role of Heavy Machine Dollies in Industrial Operations

Heavy machine dollies are indispensable tools for relocating industrial equipment weighing 2,000 to 50,000 pounds. A 2023 industry report reveals that 78% of manufacturing facilities using specialized machine moving dollies reduced equipment downtime by 41% compared to traditional forklift methods. These systems combine hydraulic lifting mechanisms with reinforced steel frames, enabling precise positioning of CNC machines, stamping presses, and turbine components without floor damage.

Technical Advantages of Modern Transport Systems

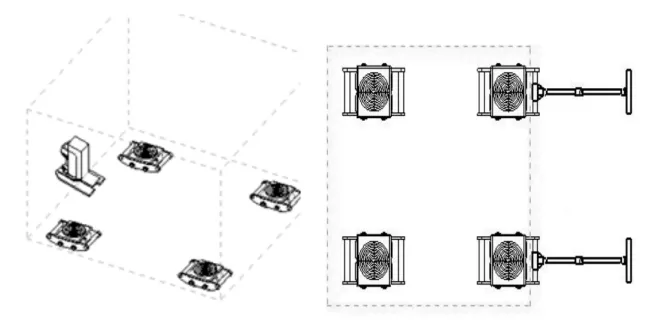

Advanced heavy machinery moving dollies now incorporate:

- Alloy-steel construction with 42% higher load capacity

- Modular designs supporting 360° rotation (±0.5° accuracy)

- Smart sensors monitoring real-time weight distribution

Field tests demonstrate that contemporary models decrease relocation-related accidents by 63% through automatic stabilization features.

Manufacturer Comparison Analysis

| Brand | Max Capacity | Wheel Type | Price Range | Warranty |

|---|---|---|---|---|

| LoadMaster Pro | 32,000 lbs | Polyurethane | $4,200-$8,500 | 5 years |

| SteelGlide HD | 45,000 lbs | Pneumatic | $6,800-$12,000 | 7 years |

| PowerMover X9 | 28,000 lbs | Cast Iron | $3,500-$7,200 | 3 years |

Custom Solutions for Specialized Needs

Leading suppliers now offer:

- Adjustable deck configurations (expandable up to 160%)

- ATEX-certified models for explosive environments

- Low-profile designs (4.3" height) for constrained spaces

Aerospace manufacturers have achieved 22% faster assembly line reconfigurations using these tailored systems.

Practical Applications Across Industries

Notable implementations include:

"Relocating 28-ton injection molding machines at Bosch Automotive required 12 standard dollies versus 4 customized units, cutting project time from 14 days to 6."

Similar efficiencies were documented in power plant turbine installations and shipyard engine transfers.

Maintenance and Operational Safety

Proper maintenance extends dolly lifespan by 70%:

- Monthly load-bearing tests (ASME B30.1 standard)

- Annual frame integrity inspections

- Immediate replacement of worn polyurethane wheels

Heavy Machine Dollies in Next-Gen Manufacturing

Emerging technologies like IoT-enabled dollies are predicted to capture 34% market share by 2027. These smart systems automatically adjust to floor gradients and equipment weight distribution, reducing manual intervention by 55% in preliminary trials.

(heavy machine dollies)

FAQS on heavy machine dollies

Q: What are heavy machine dollies used for?

A: Heavy machine dollies are designed to transport large industrial equipment safely. They feature reinforced frames and high-capacity wheels to handle extreme weights. These tools are ideal for factories, construction sites, and warehouses.

Q: How do machine moving dollies differ from standard dollies?

A: Machine moving dollies have higher weight tolerances (often 1,000+ lbs) and durable steel construction. They often include locking wheels and adjustable straps for securing loads. Standard dollies lack these heavy-duty features.

Q: What weight capacity should heavy machinery moving dollies have?

A: Capacity depends on the machinery, but industrial models typically range from 2,000 to 20,000 lbs. Always choose dollies exceeding your equipment's weight by 25% for safety. Specialized units can handle even heavier loads.

Q: Can heavy machine dollies navigate uneven surfaces?

A: Yes, models with pneumatic wheels or all-terrain treads can manage rough floors and outdoor terrain. Ensure wheel material (polyurethane/rubber) matches your environment. Avoid using rigid-wheel dollies on gravel or slopes.

Q: How to maintain heavy machinery moving dollies?

A: Regularly clean debris from wheels and inspect bearings. Lubricate moving parts every 3-6 months. Replace cracked wheels or bent frames immediately to prevent accidents.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025