Feb . 13, 2025 12:50

Back to list

industrial equipment relocation

Industrial equipment relocation is an intricate task that requires a blend of expertise, precision, and strategic planning. When it comes to moving hefty machinery and sensitive industrial components, businesses can't afford to cut corners. This article dives into the nuances of successful industrial equipment relocation, leveraging real-world experience and professional insights to ensure a seamless transition with minimal operational disruption.

Trustworthiness is the bedrock of any relocation endeavor. Trust is built through transparency, communication, and a commitment to client satisfaction. From the initial consultation to the final reinstallation, maintaining open channels of communication is vital. It ensures that clients are informed about the process, timelines, and any potential challenges that may arise. One key aspect of establishing trust is insurance. Reliable relocation companies offer comprehensive insurance options to cover any potential damage during transit. This not only protects the client's investment but also showcases the company's confidence in its operational excellence. Transport logistics also warrant careful consideration. The choice of vehicles, the route planning, and the handling procedures during transit all contribute to a successful relocation. Using state-of-the-art equipment such as hydraulic lifts and climate-controlled containers can mitigate risks associated with transportation. The science of load distribution and securing machinery for transit is another critical area where expertise enhances safety and efficiency. Upon arrival at the new location, the reinstallation process is the final test of a successful relocation. It requires a reverse engineering approach careful reassembly and precise calibration. In high-stakes environments like semiconductor manufacturing, even the slightest misalignment can lead to production setbacks. Thus, employing advanced tools for alignment and commissioning ensures that machinery is ready to hit the ground running. In conclusion, the journey of industrial equipment relocation is fraught with challenges but navigated with ease through a blend of experience, expertise, authoritativeness, and trustworthiness. Every industrial move is unique, demanding a tailored approach that respects both the complexity of the machinery and the specific requirements of the industry. By choosing a relocation partner that embodies these qualities, businesses can achieve seamless transitions that underpin operational continuity and success.

Trustworthiness is the bedrock of any relocation endeavor. Trust is built through transparency, communication, and a commitment to client satisfaction. From the initial consultation to the final reinstallation, maintaining open channels of communication is vital. It ensures that clients are informed about the process, timelines, and any potential challenges that may arise. One key aspect of establishing trust is insurance. Reliable relocation companies offer comprehensive insurance options to cover any potential damage during transit. This not only protects the client's investment but also showcases the company's confidence in its operational excellence. Transport logistics also warrant careful consideration. The choice of vehicles, the route planning, and the handling procedures during transit all contribute to a successful relocation. Using state-of-the-art equipment such as hydraulic lifts and climate-controlled containers can mitigate risks associated with transportation. The science of load distribution and securing machinery for transit is another critical area where expertise enhances safety and efficiency. Upon arrival at the new location, the reinstallation process is the final test of a successful relocation. It requires a reverse engineering approach careful reassembly and precise calibration. In high-stakes environments like semiconductor manufacturing, even the slightest misalignment can lead to production setbacks. Thus, employing advanced tools for alignment and commissioning ensures that machinery is ready to hit the ground running. In conclusion, the journey of industrial equipment relocation is fraught with challenges but navigated with ease through a blend of experience, expertise, authoritativeness, and trustworthiness. Every industrial move is unique, demanding a tailored approach that respects both the complexity of the machinery and the specific requirements of the industry. By choosing a relocation partner that embodies these qualities, businesses can achieve seamless transitions that underpin operational continuity and success.

Latest news

-

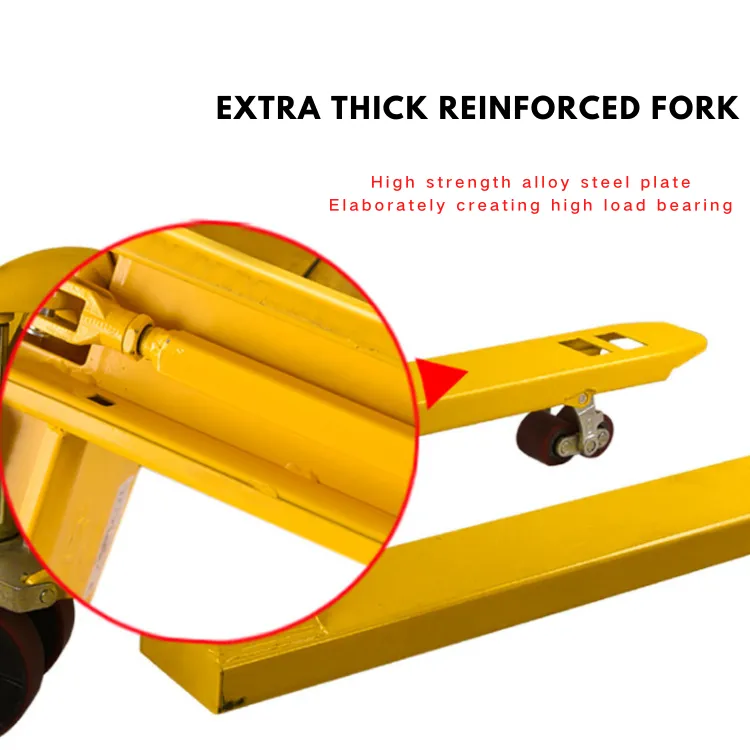

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

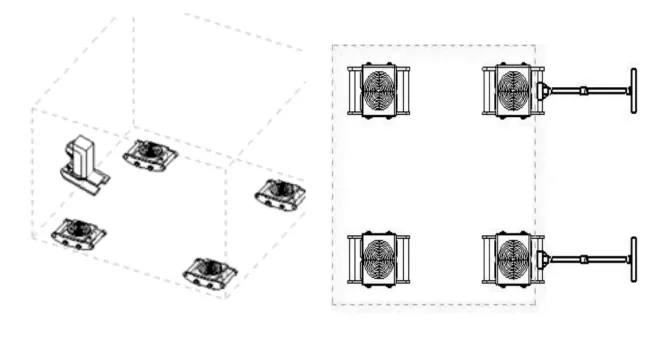

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025