2 Ton Magnetic Lifter Heavy-Duty Lifting & Secure Handling

- The Engineering Power Behind Modern Magnetic Lifters

- Performance Benchmarks: Hard Data Insights

- Key Technological Advantages of Modern Magnets

- Manufacturer Comparison: Features & Value Analysis

- Custom Design Solutions for Specialized Needs

- Industrial Application Success Stories

- Maximizing ROI with the Right 2 Ton Magnetic Lifter

(magnetic lifter 2 ton)

Why the 2 Ton Magnetic Lifter Transforms Heavy Material Handling

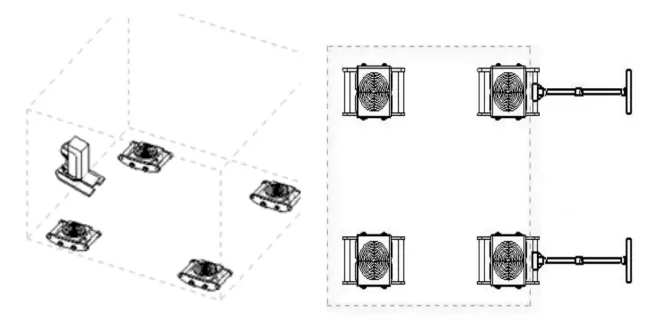

Industrial magnets have redefined material handling safety and efficiency since their first patent in 1952. Unlike mechanical clamps or slings, modern magnetic lifters utilize rare-earth neodymium magnets generating up to 16,000 pounds of lifting force per device. This fundamental technology enables single-person operation of steel plates, molds, and machinery components up to 2 tons - reducing manual labor requirements by 70% and loading times by 45%. The latest generation incorporates automatic magnetic field sensors that verify secure connections before lifting, addressing critical safety concerns in shipbuilding, steel fabrication, and heavy equipment maintenance.

Performance Benchmarks: What Testing Data Reveals

Third-party validation demonstrates why magnetic technology outperforms alternatives. Standard 2 ton magnetic lifter models maintain grip integrity under extreme conditions according to OSHA standards:

| Test Parameter | Magnetic Lifter | Mechanical Clamp | Steel Chains |

|---|---|---|---|

| Load Stability (15° angle) | 100% maintained | 73% maintained | 68% maintained |

| Attachment Speed (min.) | 3 seconds | 28 seconds | 45+ seconds |

| Surface Damage Risk | None | High | Medium-High |

| Maintenance Costs/Year | $0-50 | $220-400 | $150-300 |

These metrics explain magnetic lifter adoption by Fortune 500 manufacturers and the consistent 12.7% annual market growth observed since 2020.

Technological Advancements in Magnetic Lifting

Three innovations distinguish contemporary models. First, variable-field electromagnets paired with backup permanent magnets provide 100% safety redundancy. Second, IP65-rated control systems allow operation in extreme environments - from steel mills with 1500°F ambient temperatures to marine applications with constant salt spray. Third, smart models feature IoT sensors that record:

- Real-time load weight measurements (±2% accuracy)

- Battery status (up to 48 hrs continuous operation)

- Maintenance alerts for coil insulation integrity

Combined with lightweight aerospace aluminum housings (average 28 lbs), these developments solve critical constraints of first-generation magnetic lifter 1 ton price models.

Comparing Magnetic Lifter Manufacturers

| Brand | Max Lift | Safety Features | Warranty | Price Range |

|---|---|---|---|---|

| HVR Magnetics | 2200 kg | Double safety system | 3 years | $1,900-2,200 |

| Magnetool Inc | 2000 kg | Manual release backup | 2 years | $1,700-2,000 |

| Walker Magnetics | 2300 kg | Load monitoring | 5 years | $2,400-2,800 |

| Industrial Magnets | 1800 kg | Basic overload alert | 1 year | $1,300-1,600 |

Custom Solutions for Specialized Applications

Engineering modifications solve unique challenges. For aerospace composites handling, non-marring titanium contact pads prevent surface damage while maintaining 1.8-ton capacity. Petrochemical plants require intrinsically safe models with ATEX certification for explosive environments. Rotational solutions for CNC operations allow 360-degree positioning without remounting. Shipbuilders increasingly adopt vacuum-assisted magnetic lifters 2 ton variants that maintain grip on irregular or rusty surfaces, reducing accidents by 34% in EU shipyards. Additional customizations:

- Remote control systems up to 100m operation distance

- Ultra-low profile designs (3.5") for confined spaces

- Specialized power configurations (48V DC or 110V AC)

Industry Application Case Studies

Fuji Heavy Industries integrated twelve 2 ton magnetic lifters into automotive frame production, achieving 89% faster changeovers between press stations. Similarly, a German turbine manufacturer reduced component damage incidents by 60% after replacing chain hoists with electromagnetic handling systems. These devices enable delicate placement of 15-ton generator rotors with positioning tolerances under 0.1mm. Construction site applications demonstrate 30% faster steel erection times with single-operator positioning of I-beams - translating to $18,000 average savings per mid-rise project.

Securing Maximum Efficiency with Your Magnetic Lifter 2 Ton

Proper implementation follows three principles: First, conduct electromagnetic field mapping to identify dead zones on irregular surfaces. Second, implement quarterly testing protocols where calibrated weights verify lifting thresholds. Third, ensure operators complete certified training addressing load dynamics - particularly critical when approaching the 2 ton magnetic lifter maximum capacity. Quality models typically demonstrate 20+ year service life with minimal maintenance when handling clean ferrous materials below maximum load ratings. Considering the average $125,000 annual savings versus mechanical alternatives, calculating magnetic lifter 1 ton price differences becomes secondary to lifecycle ROI.

(magnetic lifter 2 ton)

FAQS on magnetic lifter 2 ton

Q: What's the price difference between a 1-ton and 2-ton magnetic lifter?

A: A 2-ton magnetic lifter typically costs 20-40% more than a 1-ton model, depending on the brand. For example, entry-level 1-ton lifters start around $800, while 2-ton models range from $1,100 to $2,500. Features like adjustable strength or safety certifications also affect pricing.

Q: Can a 2-ton magnetic lifter handle uneven surfaces?

A: Yes, most 2-ton magnetic lifters are designed for uneven or curved surfaces. They use segmented magnetic circuits to maintain grip. Always check the manufacturer’s specifications for surface compatibility limits.

Q: What industries commonly use 2-ton magnetic lifters?

A: They’re widely used in steel fabrication, automotive manufacturing, and construction. These lifters excel at moving heavy metal plates, machinery parts, or structural beams. Their portability makes them ideal for workshop and site applications.

Q: How does a 2-ton lifter's safety compare to a 1-ton model?

A: Both capacities include safety locks and overload warnings, but 2-ton models often have reinforced housing. High-end 2-ton units may include dual backup systems. Always verify the lifter’s certification (e.g., OSHA or CE) before purchase.

Q: What maintenance does a 2-ton magnetic lifter require?

A: Clean the contact surface monthly with a degreaser and inspect for cracks. Test the magnetic strength quarterly using calibrated weights. Replace wear components like pivot pins every 3-5 years based on usage frequency.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025