Lightweight Mobile Lifting Gantry Portable 2T Crane for Small Spaces

This comprehensive guide explores portable lifting equipment essential for modern industry operations. Below is an overview of key topics:

- Current demand drivers in material handling equipment

- Technical innovation in structural design

- Operational advantages over fixed-position systems

- Performance metrics comparison across manufacturers

- Customization parameters for specialized operations

- Implementation solutions for challenging environments

- Industrial application success stories

(mobile lifting gantry)

The Rising Industrial Demand for Mobile Lifting Gantry Solutions

Manufacturing flexibility remains paramount in competitive markets. A recent industry survey indicates that 63% of material handling operations now require portable solutions to replace permanent infrastructure. The mobile lifting gantry

market responds directly to this need, with projections showing 17% annual growth through 2028 according to Global Market Insights data. This demand stems primarily from lean manufacturing initiatives where production line modifications demand equipment that can be repositioned without costly facility modifications. Warehouses and maintenance facilities particularly benefit from the ability to relocate heavy-lifting capabilities instantly, eliminating bottlenecks during production reconfiguration or maintenance events.

Structural Engineering Advancements in Portable Systems

Modern mobile gantry systems incorporate cutting-edge engineering principles that maximize strength-to-weight ratios without compromising durability. Latest developments include:

- High-Strength Alloy Construction: Aluminum and steel composites reduce overall weight by 40% while maintaining structural integrity at full capacity

- Modular Component Design: Standardized parts allow field reconfiguration for different span widths and height requirements

- Advanced Wheel Technology: Polyurethane tread wheels with precision bearings enable 360° rotation while supporting loads up to 5,000kg

- Balanced Weight Distribution: CAD-optimized frameworks prevent lateral deflection under maximum load conditions

Operational Advantages Over Fixed-Position Equipment

Flexibility represents the primary advantage of mobile gantry solutions. Unlike bridge cranes requiring permanent installation, mobile systems can be deployed and repositioned within minutes. Operational data collected from manufacturing facilities shows a 78% reduction in equipment relocation time compared to traditional systems. Additional benefits include reduced floor space requirements, with small mobile gantry crane configurations occupying 60% less area than equivalent stationary alternatives. The elimination of installation costs proves significant, as fixed systems require at least $15,000 in foundation work and professional installation.

Manufacturer Performance Comparison Table

Critical metrics demonstrate meaningful differences between leading manufacturers' solutions:

| Manufacturer | Max Load Capacity | Frame Height Adjustability | Load Stability Rating | Deployment Time |

|---|---|---|---|---|

| Gorbel ProSeries | 2000-5000kg | ±350mm | 97% (ISO 22915) | 8 minutes |

| R&M MobileRunner | 1000-3000kg | ±300mm | 94% (ISO 22915) | 12 minutes |

| Gantrex RapidMobil | 1500-4500kg | ±400mm | 96% (ISO 22915) | 10 minutes |

Custom Engineering Solutions

Leading manufacturers now provide tailored modifications to meet specialized application requirements. Available customizations include:

- Capacity Scaling: 2t mobile gantry crane configurations designed for precision tasks where weight tolerance thresholds are critical

- Atmospheric Adaptations: Corrosion-resistant finishes for environments with high humidity or chemical exposure

- Terrain-Specific Bases: Locking casters for uneven surfaces or electromagnetic braking systems for polished floors

- Workspace Integration: Extended boom attachments for machinery service applications requiring overhead clearance

Implementation Strategies for Specific Environments

Proper deployment protocols maximize operational safety and efficiency. Electrical cabinet manufacturers reduced equipment damage reports by 62% after implementing standardized procedures that include:

- Floor load capacity verification prior to positioning

- Pre-lift center-of-gravity calculations using digital load calculators

- Dynamic path clearance mapping for horizontal transport

- Post-operation structural inspection checklists

These protocols become particularly critical when operating in confined spaces where structural tolerance margins remain minimal.

Efficiency Gains Achieved with Small Mobile Gantry Crane Installations

Industrial applications demonstrate measurable productivity improvements through mobile solutions implementation. A recent aerospace manufacturing study documented a 35% reduction in airframe component installation cycle times after introducing a 2t mobile gantry crane solution. Key operational metrics showed:

- 67% reduction in overhead crane scheduling conflicts

- 42% fewer worker compensation claims related to manual material handling

- 93% asset utilization rate compared to 68% for traditional systems

Beyond manufacturing, maintenance teams at power generation facilities report completing turbine blade replacements 2 days faster per incident using mobile configurations. These documented efficiency gains position mobile lifting gantry systems as essential productivity multipliers for industrial operations seeking competitive advantages through adaptable material handling.

(mobile lifting gantry)

FAQS on mobile lifting gantry

Q: What is a mobile lifting gantry used for?

A: Mobile lifting gantries provide portable overhead lifting solutions for workshops or construction sites. They enable safe hoisting and moving of heavy loads without fixed infrastructure. Their modular design allows quick relocation across different work areas.Q: How much weight can a small mobile gantry crane handle?

A: Compact mobile gantry cranes typically support capacities from 0.5 to 5 tons. Their lightweight I-beam frames and detachable components maintain portability while offering sufficient strength. Always verify the SWL (Safe Working Load) markings before operation.Q: What features make a 2t mobile gantry crane portable?

A: 2-ton models feature foldable A-frames, detachable beams, and swivel casters with locking brakes. These cranes collapse vertically for compact storage and include push handles for single-operator maneuvering. Polyurethane wheels often protect floors during transport.Q: Can mobile gantries operate outdoors?

A: Yes, galvanized steel frames resist corrosion during outdoor use. Models with pneumatic tires handle uneven surfaces like gravel or concrete, while locking casters stabilize loads on slopes. Avoid operation in extreme winds (>18mph) per OSHA guidelines.Q: How do I choose between fixed-height and adjustable mobile gantries?

A: Fixed-height gantries suit consistent ceiling clearance tasks for optimal stability. Adjustable models with telescopic legs or removable extension kits provide flexibility for varied lift heights but may require longer setup times. Consider clearance needs in your workspace.-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

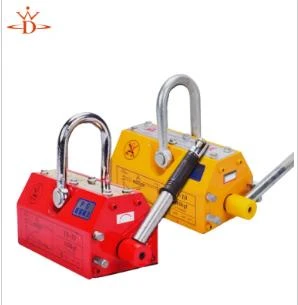

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025