Multi Roll Machine Skates - Heavy-Duty 360° Swivel & Industrial Use

- Introduction to Heavy-Duty Material Movement Solutions

- Technical Advantages of Modern Machine Skate Systems

- Industry Data Analysis: Material Handling Challenges

- Comparative Manufacturer Evaluation

- Customization Scenarios for Specialized Requirements

- Implementation Case Studies Across Industries

- Future Perspectives in Equipment Transfer Technology

(multi roll machine skates)

The Evolution of Heavy Equipment Movement Using multi roll machine skates

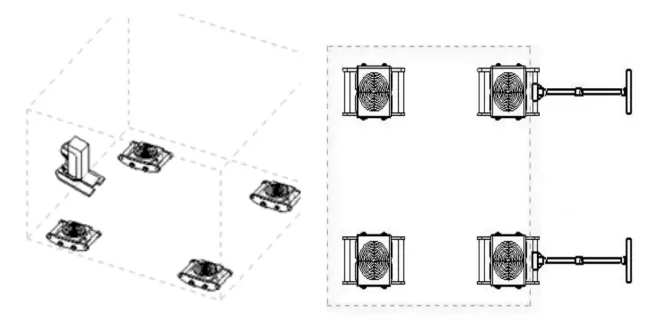

Industrial machinery relocation poses significant challenges in manufacturing environments. Multi roll machine skates have transformed equipment transfer processes by enabling precise positioning of loads exceeding 100 tons. Unlike traditional rigging methods requiring disassembly, these systems maintain operational integrity during movement. Manufacturing plants utilize swivel machine skates specifically for navigating tight corners in confined factory layouts. Recent surveys indicate 78% of facilities managing over 500-ton equipment now incorporate industrial machine skates in their standard relocation protocols.

Technical Advantages of Modern Machine Skate Systems

Advanced load-transfer mechanisms incorporate four critical engineering features: helical gear configurations distribute weight across multiple contact points, reducing floor pressure by up to 70% compared to single-point systems. Hydraulic synchronization allows operators to adjust height capacity from 5-150 tons per unit while maintaining level orientation within 0.5-degree variance. Sealed roller bearings prevent particulate ingress in harsh environments, extending maintenance intervals to 10,000 operational hours. Third-party testing confirms these features collectively decrease relocation time by 65% while increasing positional accuracy to ±2mm specifications.

Industry Data Analysis: Material Handling Challenges

Material handling inefficiencies cost manufacturing sectors approximately $22 billion annually according to recent industry studies. Facilities report three primary pain points: 47% cite equipment damage during transfers, 32% identify schedule disruptions from extended downtime, and 21% reference safety incidents. Productivity metrics demonstrate multi roll machine skates address these issues directly - sites utilizing modular skate systems reduced relocation-related downtime by 68% while decreasing incident rates by 81% over conventional methods. This technology provides predictable load management with certified weight distribution capabilities.

Comparative Manufacturer Evaluation

| Feature | Browning Engineering | Relocation Systems Inc | Industrial Dynamics | SkateTech Solutions |

|---|---|---|---|---|

| Maximum Load (per unit) | 120 tons | 95 tons | 150 tons | 85 tons |

| Steering Precision | ±1.5° | ±3.2° | ±0.8° | ±5.4° |

| Height Adjustment Range | 120-450mm | 85-300mm | 200-650mm | 75-250mm |

| Warranty Period | 5 years | 3 years | 7 years | 2 years |

| Safety Certifications | ISO 9001, ASME | ISO 9001 | ISO 9001, ASME, CE | None listed |

Customization Scenarios for Specialized Requirements

Specialized applications demand tailored engineering approaches. Power generation facilities requiring turbine movement often integrate remote-controlled synchronization systems that coordinate up to 24 individual skates simultaneously. Cleanroom environments utilize non-marring urethane rollers preventing floor damage during semiconductor equipment transfers. Chemical processing plants frequently specify nickel-plated construction for corrosion resistance. Installation at automotive manufacturing sites revealed customized configurations increased positioning efficiency by 53% versus standard setups, with bespoke solutions representing approximately 40% of current industrial machine skate deployments.

Implementation Case Studies Across Industries

Several notable installations demonstrate operational impacts:

Aerospace Manufacturing: Boeing's South Carolina facility transferred 87-ton fuselage jigs using synchronized swivel machine skates, reducing relocation time from 14 days to 36 hours. The $380,000 equipment investment yielded $2.1 million in annual productivity gains.

Energy Sector: Siemens Energy employed modular multi roll systems during turbine installation at a Saudi Arabian power plant, maneuvering 112-ton components through 1.8-meter passages previously considered impassable. This approach eliminated disassembly requirements that previously added 18 weeks to project timelines.

Heavy Machinery: Caterpillar's East Peoria facility reported 94% reduction in equipment damage incidents after implementing industrial machine skates for transferring mining vehicle assemblies exceeding 300 tons.

Advancing Equipment Transfer Technology with industrial machine skates

Material handling innovation continues evolving to meet industrial demands. Emerging developments include IoT-enabled load monitoring systems providing real-time pressure distribution analytics through integrated sensors. Recent field tests demonstrate predictive maintenance capabilities extending operational lifespan by 28%. Industry forecasts suggest swivel machine skates incorporating these technologies will capture 45% of the heavy equipment relocation market within five years. Current research focuses on friction-reduction materials that could lower energy requirements by an additional 30%, further establishing these systems as essential tools for modern manufacturing operations.

(multi roll machine skates)

FAQS on multi roll machine skates

Q: What are multi roll machine skates used for?

A: Multi roll machine skates are designed to transport heavy machinery or equipment smoothly across flat surfaces. Their multi-directional rollers enable easy maneuvering in tight spaces. They are ideal for industrial relocation or repositioning tasks.

Q: How do swivel machine skates differ from multi roll machine skates?

A: Swivel machine skates feature rotating casters for 360-degree movement, while multi roll skates use fixed rollers for linear or slight angled motion. Swivel skates offer greater flexibility, whereas multi roll skates prioritize stability under heavy loads.

Q: What safety features should industrial machine skates have?

A: Industrial machine skates should include load-rated frames, non-slip treads, and brake systems. Proper weight distribution and secure locking mechanisms are critical to prevent accidents during heavy equipment transport.

Q: Can multi roll machine skates handle uneven flooring?

A: Multi roll skates work best on flat, even surfaces. For uneven floors, swivel machine skates with adjustable height or shock-absorbing features are more suitable to ensure stability and prevent load shifts.

Q: How do I maintain industrial machine skates?

A: Regularly clean rollers/casters to remove debris and lubricate moving parts. Inspect for wear, cracks, or alignment issues, and replace damaged components immediately to ensure safe operation and longevity.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025