Feb . 15, 2025 09:05

Back to list

lifter magnet

Exploring the dynamic realm of lifter magnets unveils an intricate blend of engineering brilliance and practical applications. These sophisticated tools have revolutionized how companies handle heavy metals and materials, ultimately enhancing operational efficiency and safety. Understanding the unparalleled benefits and engineering prowess behind lifter magnets is key to appreciating their pivotal role across numerous industries.

As technology progresses, the engineering behind lifter magnets continues to advance, introducing more efficient, eco-friendly options to industries. Innovations focus on minimizing energy consumption, enhancing magnetic strength, and incorporating smart technology to monitor and optimize performance. Such technological strides not only improve the equipment's reliability and longevity but also contribute to a more sustainable industrial practice by reducing energy requirements and material wastage. When selecting a lifter magnet, businesses should conduct meticulous evaluations to ensure the chosen model aligns with their operational needs and environmental conditions. Factors such as load capacity, the nature of the materials handled, and the working environment's temperature and humidity can significantly influence the lifter magnet's performance. Consulting with magnet manufacturers and industry experts is essential in making informed decisions that maximize efficiency while adhering to safety standards. Trustworthiness in lifter magnets also comes from selecting reputable manufacturers and adhering to industry standards. Companies producing these magnets should be certified in quality and compliance, offering warranties and after-sales support that safeguard investments. Such reputable manufacturers invest heavily in research and development, consistently bringing improvements that align with industry demands and sustainability goals. Ultimately, lifter magnets represent a vital convergence of safety, efficiency, and innovation in material handling. Their unique characteristics contribute to smoother operations and safer workplaces, enhancing productivity across various domains. As industries continue to evolve in complexity and scale, lifter magnets will undoubtedly remain a cornerstone of industrial progress, reflecting continuous improvements in technology and engineering excellence.

As technology progresses, the engineering behind lifter magnets continues to advance, introducing more efficient, eco-friendly options to industries. Innovations focus on minimizing energy consumption, enhancing magnetic strength, and incorporating smart technology to monitor and optimize performance. Such technological strides not only improve the equipment's reliability and longevity but also contribute to a more sustainable industrial practice by reducing energy requirements and material wastage. When selecting a lifter magnet, businesses should conduct meticulous evaluations to ensure the chosen model aligns with their operational needs and environmental conditions. Factors such as load capacity, the nature of the materials handled, and the working environment's temperature and humidity can significantly influence the lifter magnet's performance. Consulting with magnet manufacturers and industry experts is essential in making informed decisions that maximize efficiency while adhering to safety standards. Trustworthiness in lifter magnets also comes from selecting reputable manufacturers and adhering to industry standards. Companies producing these magnets should be certified in quality and compliance, offering warranties and after-sales support that safeguard investments. Such reputable manufacturers invest heavily in research and development, consistently bringing improvements that align with industry demands and sustainability goals. Ultimately, lifter magnets represent a vital convergence of safety, efficiency, and innovation in material handling. Their unique characteristics contribute to smoother operations and safer workplaces, enhancing productivity across various domains. As industries continue to evolve in complexity and scale, lifter magnets will undoubtedly remain a cornerstone of industrial progress, reflecting continuous improvements in technology and engineering excellence.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

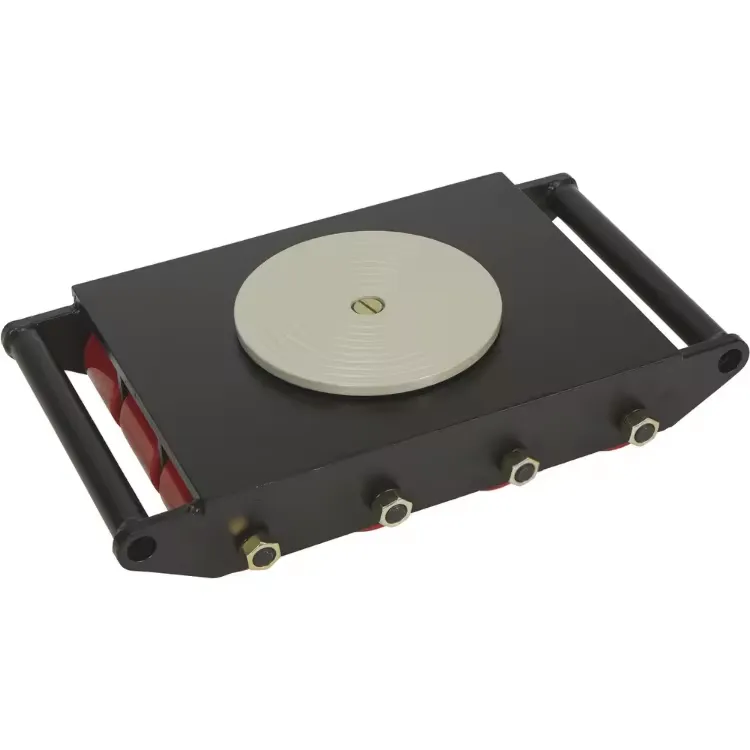

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025