Feb . 17, 2025 23:24

Back to list

travelling gantry crane

A traveling gantry crane is a monumental asset in the realm of material handling, particularly known for its versatility and efficiency in various industrial applications. With years of industry experience, one could assert that investing in such a system can transform operations across sectors, specifically in shipping yards, construction sites, and manufacturing facilities. These cranes are indispensable when heavy lifting and precise material positioning are required.

When discussing the choice of a traveling gantry crane, trust in manufacturer expertise and the quality of after-sale service emerge as critical factors. Reputable manufacturers provide thorough initial consultations to determine the specific crane configuration that best matches the operational needs. Moreover, an emphasis on comprehensive training for operators and routine maintenance checks underscores a commitment to safety standards and operational excellence. The aforementioned attributes speak to the undeniable authoritativeness of the traveling gantry crane in the industry. Stories of operational success invariably include instances of increased throughput, enhanced safety, and cost-effective material handling solutions. Indeed, this valuable tool not only meets but often exceeds the expectations of operations managers who prioritize reliability, efficiency, and safety. Trust is further solidified through user testimonials and documented case studies that highlight real-world application scenarios where consistent performance transformed business operations. Companies that have adopted these cranes often share anecdotal evidence of improved operational timelines, reduced labor costs, and heightened safety profiles. In decision-making processes surrounding equipment investments, it is imperative to place equal importance on performance metrics and supplier reputation. The credibility of a traveling gantry crane as an asset is firmly rooted in the consistent delivery of its promised benefits, safeguarded by a supplier’s commitment to quality and service excellence. In conclusion, the traveling gantry crane stands as a testament to engineering ingenuity, blending intricate design with unparalleled functionality. Its role across various industries underscores the crane's unmatched capability in driving operational success while steadfastly adhering to principles of safety and reliability.

When discussing the choice of a traveling gantry crane, trust in manufacturer expertise and the quality of after-sale service emerge as critical factors. Reputable manufacturers provide thorough initial consultations to determine the specific crane configuration that best matches the operational needs. Moreover, an emphasis on comprehensive training for operators and routine maintenance checks underscores a commitment to safety standards and operational excellence. The aforementioned attributes speak to the undeniable authoritativeness of the traveling gantry crane in the industry. Stories of operational success invariably include instances of increased throughput, enhanced safety, and cost-effective material handling solutions. Indeed, this valuable tool not only meets but often exceeds the expectations of operations managers who prioritize reliability, efficiency, and safety. Trust is further solidified through user testimonials and documented case studies that highlight real-world application scenarios where consistent performance transformed business operations. Companies that have adopted these cranes often share anecdotal evidence of improved operational timelines, reduced labor costs, and heightened safety profiles. In decision-making processes surrounding equipment investments, it is imperative to place equal importance on performance metrics and supplier reputation. The credibility of a traveling gantry crane as an asset is firmly rooted in the consistent delivery of its promised benefits, safeguarded by a supplier’s commitment to quality and service excellence. In conclusion, the traveling gantry crane stands as a testament to engineering ingenuity, blending intricate design with unparalleled functionality. Its role across various industries underscores the crane's unmatched capability in driving operational success while steadfastly adhering to principles of safety and reliability.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

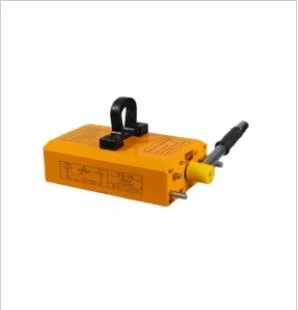

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025