Feb . 13, 2025 17:01

Back to list

machine used to move pallets

In the bustling world of modern logistics, one indispensable machine stands out the pallet mover. This equipment has evolved dramatically, transforming warehouse operations globally. When it comes to handling pallets efficiently, the choice of machine can significantly impact productivity, safety, and cost-effectiveness.

The future of pallet movement lies in automation, and Automated Guided Vehicles (AGVs) are at the forefront of this revolution. Perfect for large, high-volume warehouses, these autonomous machines require minimal human intervention, thereby significantly reducing labor costs. AGVs operate via embedded floor arrangements or advanced navigational systems like LiDAR, ensuring precise and efficient movement of pallets. Their integration into a warehouse management system (WMS) allows for seamless coordination with inventory databases, optimizing the supply chain from start to finish. Despite their initial high investment, the long-term savings and increased productivity make AGVs an attractive option for big enterprises seeking state-of-the-art technology. Choosing the Right Machine Factors to Consider Selecting the appropriate pallet moving machine involves assessing multiple factors - Warehouse Layout and Size The dimensions and configuration of your storage facility play a pivotal role. Narrow aisles necessitated by space constraints might better accommodate electric pallet jacks, whereas expansive environments could benefit from forklifts or AGVs. - Load Requirements Understanding the volume and types of goods being moved is crucial. Heavier loads may require the robust power of a forklift, while lighter, frequent movements can be efficiently handled by electric options. - Budget Constraints Evaluating the cost and projected return on investment (ROI) is essential. Initial expenses versus long-term maintenance and operational savings need consideration, especially with high-tech choices like AGVs. - Operator Safety and Training The ease of use and safety features can impact the efficiency and morale of the workforce. Machines that offer state-of-the-art safety features reduce the risk of injuries and enhance operational fluidity. Conclusion Navigating the plethora of available options for pallet moving machines can be a daunting task, yet, understanding the strengths and applications of each type ensures informed decision-making. As industries continue to evolve, the adaptation of versatile, efficient, and safe pallet-moving machines will remain a cornerstone of operational success. Embracing the right technology not only streamlines logistics but also sets a foundation for sustainable growth and competitiveness in today’s fast-paced market.

The future of pallet movement lies in automation, and Automated Guided Vehicles (AGVs) are at the forefront of this revolution. Perfect for large, high-volume warehouses, these autonomous machines require minimal human intervention, thereby significantly reducing labor costs. AGVs operate via embedded floor arrangements or advanced navigational systems like LiDAR, ensuring precise and efficient movement of pallets. Their integration into a warehouse management system (WMS) allows for seamless coordination with inventory databases, optimizing the supply chain from start to finish. Despite their initial high investment, the long-term savings and increased productivity make AGVs an attractive option for big enterprises seeking state-of-the-art technology. Choosing the Right Machine Factors to Consider Selecting the appropriate pallet moving machine involves assessing multiple factors - Warehouse Layout and Size The dimensions and configuration of your storage facility play a pivotal role. Narrow aisles necessitated by space constraints might better accommodate electric pallet jacks, whereas expansive environments could benefit from forklifts or AGVs. - Load Requirements Understanding the volume and types of goods being moved is crucial. Heavier loads may require the robust power of a forklift, while lighter, frequent movements can be efficiently handled by electric options. - Budget Constraints Evaluating the cost and projected return on investment (ROI) is essential. Initial expenses versus long-term maintenance and operational savings need consideration, especially with high-tech choices like AGVs. - Operator Safety and Training The ease of use and safety features can impact the efficiency and morale of the workforce. Machines that offer state-of-the-art safety features reduce the risk of injuries and enhance operational fluidity. Conclusion Navigating the plethora of available options for pallet moving machines can be a daunting task, yet, understanding the strengths and applications of each type ensures informed decision-making. As industries continue to evolve, the adaptation of versatile, efficient, and safe pallet-moving machines will remain a cornerstone of operational success. Embracing the right technology not only streamlines logistics but also sets a foundation for sustainable growth and competitiveness in today’s fast-paced market.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

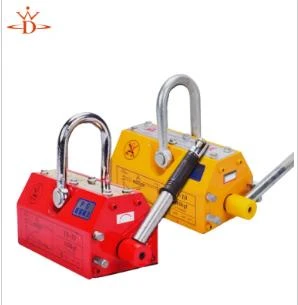

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025