High-Performance Overhead Travelling Crane New Travelling Gantry Cranes Manufacturer

- Introduction to overhead travelling crane

s and their modern relevance - Statistical analysis of market growth and industry trends

- Technical advantages and innovation highlights in crane design

- Manufacturer comparison focusing on quality, capability, and support

- Customisation options and specification considerations for unique applications

- Application case studies demonstrating practical utility

- Conclusion: The role of overhead travelling cranes in contemporary industrial progress

(overhead travelling crane)

Overhead Travelling Crane: Defining the Backbone of Modern Material Handling

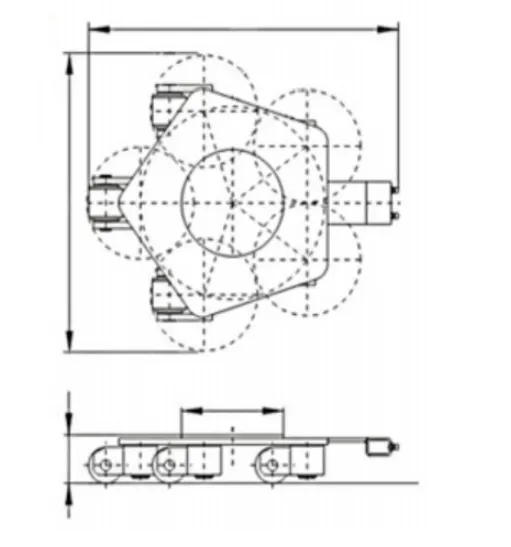

Overhead travelling cranes have fundamentally transformed material handling operations across diverse industries, functioning as a pivotal infrastructure component in manufacturing, warehousing, logistics, and shipbuilding. These cranes, suspended from an overhead structure, provide seamless lateral and longitudinal movement along a fixed rail system, enabling efficient lifting and transfer of hefty loads. In recent years, the demand for new overhead travelling cranes has surged due to the accelerated pace of industrial automation and pressing requirements for larger load capacities, higher precision, and enhanced safety standards. The current market encompasses various models, including the classic single and double girder designs, as well as the specialized travelling gantry crane variant, all of which offer tailored functionalities to suit specific environments. This introductory discussion sets the stage for a deeper examination of statistical trends, technological breakthroughs, and real-world implementations that are shaping the evolution of overhead crane systems.

Market Growth: Data-Driven Insights and Future Prospects

The global overhead travelling crane market is experiencing robust growth, with market analysts projecting its valuation to reach USD 6.8 billion by 2028, up from USD 4.7 billion in 2022—an impressive CAGR of approximately 6.5%. Driving this expansion are both macroeconomic forces and sector-specific dynamics, such as the proliferation of mega-manufacturing plants, growing investments in infrastructure modernization, and the integration of smart factory solutions. Notably, Asia-Pacific leads in adoption, accounting for nearly 50% of global demand, primarily due to rapid industrialization in China, India, and Southeast Asian countries. Meanwhile, mature markets in Europe and North America are witnessing a shift towards high-value, custom-engineered solutions supported by Industry 4.0 technologies such as advanced IoT sensors, automated diagnostics, and energy-efficient drive systems. Key industrial verticals leveraging these cranes include automotive, steel, aerospace, and logistics, underscoring their universal applicability. Such data not only reflect the ongoing relevance of overhead travelling cranes but also signal opportunities for innovation and differentiation amid intensifying competition.

Advanced Design and Technology: Unlocking Performance and Efficiency

The technical landscape of overhead travelling cranes has evolved dramatically, featuring innovations that elevate operational efficiency, safety, and adaptability. Modern cranes are built with high-strength, low-weight alloys and engineered beams that enable increased load ratings without sacrificing mobility. Variable frequency drives (VFDs) are now standard, providing smooth acceleration, precise speed control, and significant energy savings—often reducing power consumption by up to 30% compared to legacy systems. Enhanced anti-sway control algorithms, enabled by state-of-the-art motion sensors, further minimize load swing and improve positioning accuracy, lowering the risk of workplace accidents and material damages. Moreover, remote diagnostics and predictive maintenance tools, powered by cloud-connected IoT devices, deliver actionable insights, enabling operators to anticipate component wear, optimize scheduling, and reduce unscheduled downtime. In high-demand environments, the integration of automation interfaces allows for seamless coordination with production lines and warehouse management systems, supporting fully autonomous or semi-automatic workflows. Collectively, these advancements not only drive tangible ROI but also bolster a safer, more productive workspace.

Comparing Leading Manufacturers: Quality, Capability, and Aftermarket Support

Choosing the right manufacturer is critical to maximizing the return on investment in new overhead travelling cranes. A comparative analysis of leading global suppliers reveals significant differences in terms of technical specifications, value-added services, warranty offerings, and lifecycle support. The following table provides a snapshot comparison among three industry frontrunners:

| Manufacturer | Max Load Capacity (tons) | Automation Level | Warranty (years) | Global Service Presence | IoT Integration |

|---|---|---|---|---|---|

| Konecranes | 500 | Full (Automated/Manual) | 3 | 70+ Countries | Advanced (TRUCONNECT) |

| Demag | 350 | Semi/Full | 2 | 60+ Countries | Smart Monitoring |

| GH Cranes & Components | 250 | Manual/Semi | 2 | 50+ Countries | Standard |

Each provider offers unique advantages: Konecranes stands out for automation and predictive analytics; Demag offers robust engineering and global reach; GH Cranes provides customized, cost-effective solutions suitable for small-to-medium operations. Thoroughly evaluating operational requirements against these differentiators helps ensure an optimal, future-ready investment.

Customised Solutions: Tailoring Overhead Crane Systems to Unique Needs

New overhead travelling cranes are rarely “off-the-shelf” products. Customisation plays a central role in aligning crane systems with the specific demands of a given operational environment. Key variables include span length, lifting height, operational frequency, ambient conditions (such as heat, humidity, or corrosive atmospheres), and required motion profiles. For example, facilities handling high-value components, such as aerospace parts, often demand super-precision gantry systems with redundant safety mechanisms and automated tracking. Heavy steel mills, in contrast, prioritize extreme load capacities, radiant heat resistance, and robust throughput. Many crane suppliers offer comprehensive design consultations, incorporating 3D modeling, finite element analysis, and dynamic simulations to validate performance before fabrication. Electrification options have also diversified, with energy recovery systems, modular cable festoons, and wireless remote controls contributing to streamlined operations. Customized operator cabins, environmental enclosures, and anti-collision tech further enhance utility and safety. Engaging collaboratively with suppliers to define the specification matrix ensures the delivered crane meets immediate operational goals and long-term scalability.

Application Scenarios: Case Studies Demonstrating Real-World Value

Success stories offer tangible evidence of the transformative impact of travelling gantry crane systems across various industries:

- Automotive Manufacturing: A German car manufacturer achieved a 22% reduction in assembly time by introducing a synchronized dual-girder overhead system with automated material tracking. IoT integration facilitated real-time production monitoring, enabling rapid response to workflow fluctuations.

- Steel Production: In India, a new overhead travelling crane with a 350-ton capacity and heat-resilient design delivered uninterrupted operation in a high-temperature rolling mill, reducing unplanned downtime by 35%.

- Warehouse and Logistics: A leading logistics provider in the US deployed a networked set of travelling gantry cranes equipped with anti-sway control, boosting daily throughput by 18% and improving safety metrics via integrated collision avoidance.

- Aerospace Manufacturing: In France, customised cranes with precise load positioning and multi-axis control capabilities enabled the handling of delicate, large-scale aerostructures, decreasing damage incidents to near zero while enhancing throughput.

These case studies highlight the diverse, application-specific benefits delivered by innovative crane technologies—ranging from increased safety and productivity to elevated service reliability and operational visibility.

The Enduring Impact of Overhead Travelling Cranes in Industrial Advancement

In summary, the overhead travelling crane remains an indispensable asset driving industrial progress on multiple fronts. From the implementation of advanced materials and automation to a landscape shaped by fierce manufacturer competition and demand for bespoke applications, these lifting systems are integral to optimizing complex workflows and securing competitive advantages across sectors. As new overhead travelling cranes increasingly adopt digital connectivity and adaptive performance features, their value proposition will only strengthen. Industry leaders and facility managers who strategically invest in the latest overhead crane technology—and collaborate with forward-thinking suppliers—can expect measurable improvements in efficiency, sustainability, and workplace safety, ensuring enduring success in a dynamic marketplace.

(overhead travelling crane)

FAQS on overhead travelling crane

Q: What is an overhead travelling crane?

A: An overhead travelling crane is a type of lifting equipment that moves along elevated rails in a facility. It is used to lift and transport heavy materials horizontally. This system enhances workflow efficiency and safety.Q: What are the main benefits of installing new overhead travelling cranes?

A: New overhead travelling cranes offer advanced safety features, improved lifting capacity, and greater reliability. They often result in lower maintenance costs. Modern cranes also enhance operational productivity.Q: How does a travelling gantry crane differ from an overhead travelling crane?

A: A travelling gantry crane runs on tracks at ground level or on wheels, while an overhead travelling crane is suspended from elevated beams. Both are used for material handling. The choice depends on facility layout and operation needs.Q: What factors should be considered when choosing an overhead travelling crane?

A: You should consider load capacity, span length, lifting height, and required mobility. Facility size and intended applications are also important. Consulting with a crane expert can ensure the best fit for your needs.Q: Are overhead travelling cranes suitable for outdoor use?

A: Most overhead travelling cranes are designed for indoor environments. However, specially engineered models can be adapted for outdoor use. Weather protection and material selection are key considerations for outdoor installations.-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025