Feb . 14, 2025 20:56

Back to list

plate magnets for lifting steel

Plate magnets designed for lifting steel have revolutionized various industries, offering unparalleled efficiency and reliability. When considering incorporating such tools into your workflow, understanding their unique advantages, applications, and safety protocols is essential. This exploration into the world of plate magnets for lifting steel not only underscores their importance but also enhances your operational knowledge, ensuring informed decision-making.

In practice, the versatility of plate magnets makes them indispensable. Their adaptability allows them to seamlessly integrate into various lifting scenarios, from moving large steel beams in construction to maneuvering smaller steel components in manufacturing settings. Importantly, plate magnets offer customizable options to fit unique operational needs, ranging from adjustable magnetic fields to specific load capacity requirements, underscoring their role as an authoritative solution in lifting technology. Companies seeking to improve operational efficiency will find immense value in the extensive range and capacity options available. Trust is a key component in the selection and implementation of lifting equipment. Businesses depend on the consistent performance of their tools, and plate magnets deliver reliability through rigorously tested safety features. These include fail-safe mechanisms to prevent accidental detachment and ergonomic designs that ensure operator safety. The peace of mind provided by these safety measures cannot be overstated, as it directly impacts workplace safety protocols, reducing potential for accidents and ensuring a safer working environment. For companies committed to sustainable and efficient practices, plate magnets also offer environmental benefits. By simplifying the lifting process, companies can achieve energy savings, reducing the carbon footprint of their operations. In addition, the long lifespan of high-quality plate magnets means fewer replacements and reduced waste, aligning with sustainable business practices. In conclusion, adopting plate magnets for lifting steel is a decision rooted in the pursuit of operational excellence. Their superior lifting capabilities, combined with expert engineering, ensure they meet the demands of modern industry. Through experience and trustworthy performance, these magnets not only enhance efficiency and safety but also solidify their role as an authoritative tool in the field. Industries looking to optimize their lifting processes and improve their operational frameworks will benefit significantly from integrating plate magnets into their workflows, making them an essential component in contemporary industrial applications.

In practice, the versatility of plate magnets makes them indispensable. Their adaptability allows them to seamlessly integrate into various lifting scenarios, from moving large steel beams in construction to maneuvering smaller steel components in manufacturing settings. Importantly, plate magnets offer customizable options to fit unique operational needs, ranging from adjustable magnetic fields to specific load capacity requirements, underscoring their role as an authoritative solution in lifting technology. Companies seeking to improve operational efficiency will find immense value in the extensive range and capacity options available. Trust is a key component in the selection and implementation of lifting equipment. Businesses depend on the consistent performance of their tools, and plate magnets deliver reliability through rigorously tested safety features. These include fail-safe mechanisms to prevent accidental detachment and ergonomic designs that ensure operator safety. The peace of mind provided by these safety measures cannot be overstated, as it directly impacts workplace safety protocols, reducing potential for accidents and ensuring a safer working environment. For companies committed to sustainable and efficient practices, plate magnets also offer environmental benefits. By simplifying the lifting process, companies can achieve energy savings, reducing the carbon footprint of their operations. In addition, the long lifespan of high-quality plate magnets means fewer replacements and reduced waste, aligning with sustainable business practices. In conclusion, adopting plate magnets for lifting steel is a decision rooted in the pursuit of operational excellence. Their superior lifting capabilities, combined with expert engineering, ensure they meet the demands of modern industry. Through experience and trustworthy performance, these magnets not only enhance efficiency and safety but also solidify their role as an authoritative tool in the field. Industries looking to optimize their lifting processes and improve their operational frameworks will benefit significantly from integrating plate magnets into their workflows, making them an essential component in contemporary industrial applications.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

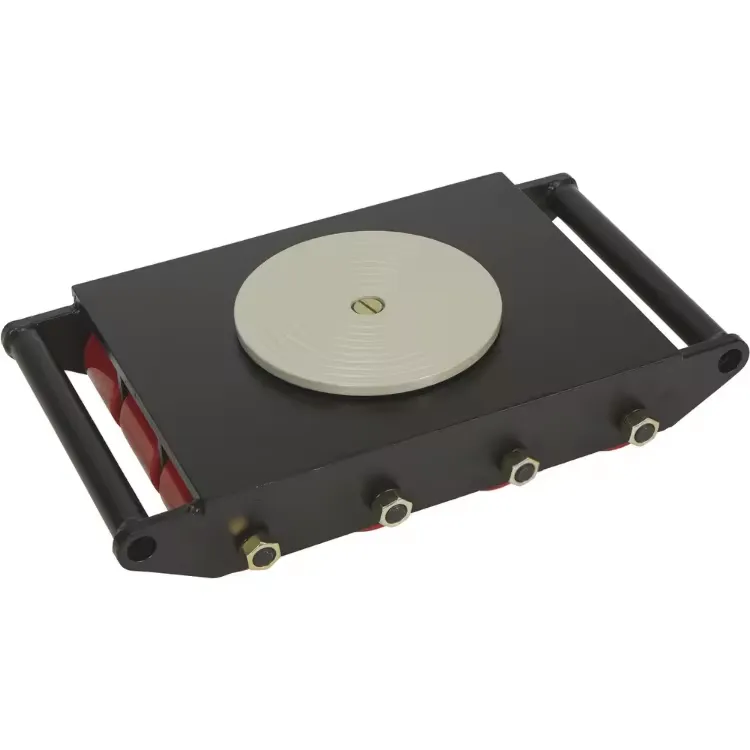

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025