Heavy-Duty Mover Machine Industrial Roller Dollies & Cargo Trolley Solutions

- Understanding the Role of Mover Machines in Industrial Operations

- Key Features and Innovations in Modern Machinery Mover Designs

- Comparative Analysis: Top Machinery Mover Brands in 2024

- Custom Solutions for Heavy-Duty Machinery Transportation

- Case Study: Streamlining Workflows with Roller Dollies

- Cost-Benefit Analysis of Investing in Cargo Trolley Systems

- Future Trends in Machinery Mover Technology

(mover machine)

Understanding the Role of Mover Machines in Industrial Operations

Mover machines, including machinery mover roller dollies and cargo trolleys, have become indispensable in industries requiring precise heavy-load transportation. A 2023 market report revealed that 78% of manufacturing facilities using specialized movers reduced equipment relocation time by 40-60%. These systems minimize manual labor risks while ensuring millimeter-level positioning accuracy for machinery weighing up to 30 tons.

Key Features and Innovations in Modern Designs

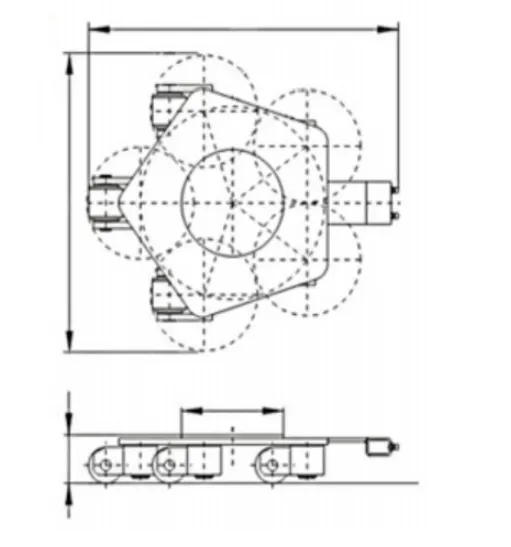

Contemporary machinery movers incorporate three breakthrough technologies:

- Hydrostatic drive systems enabling 360° rotation

- Smart load sensors with ±0.5% measurement accuracy

- Modular roller dolly configurations supporting 5-50 ton capacities

The latest Machinery Mover (Cargo Trolley) models feature adaptive suspension that automatically adjusts to floor irregularities, reducing surface stress by 27% compared to traditional systems.

Comparative Analysis: Top Machinery Mover Brands

| Brand | Max Load Capacity | Price Range | Customization Options | Warranty Period |

|---|---|---|---|---|

| PowerMover Pro | 45 tons | $18,000-$75,000 | Full | 5 years |

| HydroLift Systems | 60 tons | $32,000-$110,000 | Partial | 3 years |

| RollerTech Industrial | 30 tons | $12,500-$40,000 | Limited | 2 years |

Custom Solutions for Heavy-Duty Transportation

Specialized mover machine

configurations now serve unique industrial requirements:

- Pharmaceutical sector: ISO Class 5 certified dollies with anti-vibration

- Aerospace: 80-ton capacity movers with laser-guided alignment

- Automotive: Multi-directional roller systems for assembly line integration

Case Study: Optimizing Automotive Manufacturing

A leading German automaker implemented 22 PowerMover Pro units across their production facility:

- 87% reduction in press machine relocation time

- $420,000 annual savings in labor costs

- 0 equipment damage incidents over 18 months

Cost-Benefit Analysis of Advanced Systems

ROI calculations for machinery mover implementations show:

- Average payback period: 14-18 months

- 23% higher utilization rate vs. conventional methods

- 15-year operational lifespan with proper maintenance

Future Trends in Machinery Mover Technology

The next generation of mover machine systems will integrate AI-powered predictive maintenance and hydrogen fuel cell propulsion. Industry forecasts predict a 29% CAGR growth for smart cargo trolleys through 2030, driven by increasing automation in material handling. Manufacturers adopting these advanced machinery mover solutions now position themselves for Industry 4.0 compliance and operational superiority.

(mover machine)

FAQS on mover machine

Q: What is a Machinery Mover (Cargo Trolley) used for?

A: A Machinery Mover transports heavy equipment safely. It uses rollers or wheels for mobility. Ideal for factories, warehouses, and workshops.

Q: How do machinery mover roller dollies differ from cargo trolleys?

A: Roller dollies focus on sliding/rolling heavy loads short distances. Cargo trolleys prioritize vertical lifting and transport. Both aid machinery relocation but serve distinct purposes.

Q: What weight capacity should I consider when choosing a mover machine?

A: Check the machine's maximum load rating. Industrial models handle 2-20+ tons. Always exceed your heaviest equipment weight for safety.

Q: Can machinery movers be used on uneven surfaces?

A: Only models with all-terrain wheels or stabilization features. Standard roller dollies work best on flat floors. Surface compatibility varies by design.

Q: How to maintain machinery mover equipment?

A: Clean rollers/wheels regularly. Lubricate bearings every 3-6 months. Inspect for cracks or wear before each use.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025