Dawei Straight Type Machinery Mover | 6-18T Load Capacity

Advancing Industrial Mobility: The Dawei Machinery Mover Straight Type, Rated Load 6000-18000 KGS.

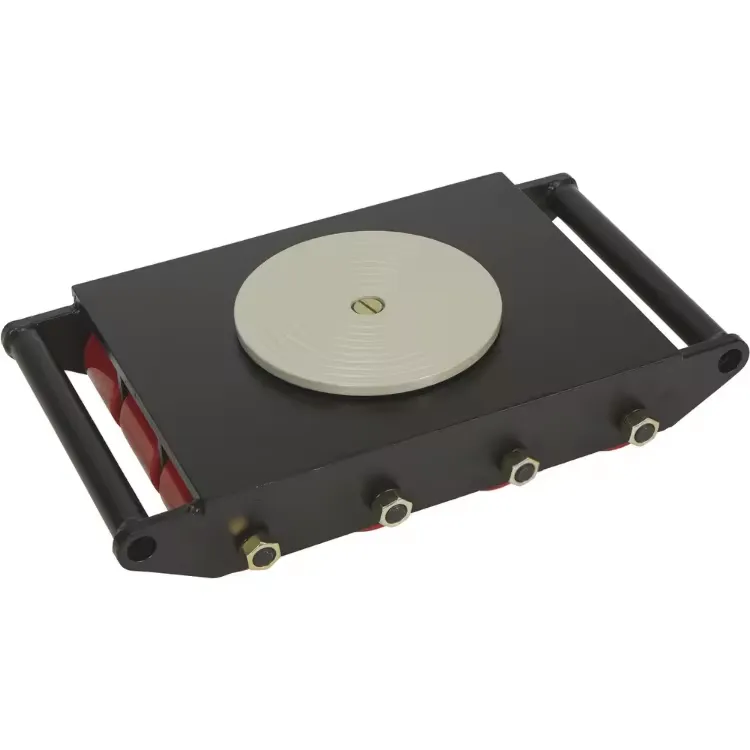

In the intricate landscape of modern industrial operations, the efficient and safe relocation of heavy machinery is paramount. Businesses across sectors, from precision manufacturing to heavy-duty construction, consistently seek robust solutions that minimize downtime and mitigate risks. The market for machinery movers is evolving, driven by demands for higher load capacities, improved maneuverability, and enhanced safety features. Emerging trends point towards integrated smart technologies and materials science advancements that promise greater durability and reduced maintenance. The Dawei Machinery Mover Straight Type, a specialized solution designed for seamless, linear movement of massive equipment, addresses these critical industry needs, offering unparalleled performance for loads ranging from 6000 KGS to 18000 KGS.

This specialized equipment is engineered to provide precise control and stability, crucial for navigating complex industrial environments where space is often limited and operational continuity is essential. Its straight-line capability ensures that heavy machinery can be positioned with pinpoint accuracy, avoiding potential damage to equipment or facility infrastructure. The robust construction and optimized wheel design of the Dawei Machinery Mover Straight Type make it a preferred choice for companies aiming to enhance their logistical capabilities and ensure the integrity of their valuable assets during relocation processes.

Unveiling the Engineering: Technical Parameters of Dawei Machinery Mover

The efficacy of any industrial equipment lies in its precise technical specifications and the meticulous engineering behind its design. The Dawei Machinery Mover Straight Type is a testament to this principle, built to facilitate the heavy lifting and movement requirements of diverse industrial applications. Understanding its core parameters is crucial for optimal deployment and ensures compatibility with specific operational demands. Below is a detailed table outlining the key specifications for the Dawei Machinery Mover Straight Type with its impressive Rated Load of 6000-18000 KGS.

| Parameter | Value/Description |

|---|---|

| Product Model | Dawei Machinery Mover Straight Type |

| Rated Load Capacity | 6000 KGS - 18000 KGS (Model Dependent) |

| Wheel Material | High-Grade PU (Polyurethane) for floor protection & low friction |

| Number of Wheels | 4-8 (Varies by load capacity for optimal distribution) |

| Overall Dimensions (Approx.) | L: 300-500mm, W: 250-400mm, H: 100-150mm (compact design) |

| Net Weight | 10 KGS - 35 KGS (depending on load capacity) |

| Steering Mechanism | Straight-line, non-swivel (designed for controlled linear movement) |

| Surface Finish | Powder-coated for enhanced corrosion resistance |

| Operating Temperature | -20°C to +60°C |

| Safety Factor | Minimum 1.5:1 (over rated load for safety) |

These parameters underscore the robust build and reliable performance of the Dawei Machinery Mover Straight Type. The meticulous selection of high-grade Polyurethane for wheels ensures minimal floor damage and reduced friction during movement, contributing to energy efficiency. Furthermore, the compact yet powerful design allows for deployment in constrained industrial spaces, a significant advantage in modern manufacturing layouts. The straight-line mechanism ensures predictable and controlled motion, critical for the precision required in handling delicate, heavy machinery.

Precision Engineering: The Manufacturing Process of Dawei Machinery Movers

The superior performance and longevity of the Dawei Machinery Mover Straight Type are not accidental; they are the direct result of a rigorously controlled manufacturing process that adheres to the highest industry standards. From raw material sourcing to final inspection, every step is optimized for quality and durability. The primary materials utilized include high-strength alloy steel for the main chassis, chosen for its exceptional tensile strength and fatigue resistance, and specialized polyurethane compounds for the wheels, engineered for optimal load bearing and floor protection.

The manufacturing journey begins with precision forging of the main structural components, which enhances grain structure and mechanical properties, making the mover exceptionally resilient under heavy loads. This is followed by advanced CNC machining, ensuring exact dimensions and tight tolerances, critical for the precise alignment and smooth operation of the wheels and bearings. Each component then undergoes a multi-stage surface treatment, including sandblasting and a durable powder coating, which provides superior corrosion resistance—a vital attribute for equipment operating in harsh industrial environments, including those with exposure to chemicals or moisture common in petrochemical and water treatment facilities.

Quality assurance is integral to the Dawei process. Every batch is subjected to comprehensive non-destructive testing (NDT), including ultrasonic and magnetic particle inspections, to detect any internal flaws. The final assembly undergoes rigorous functional testing, including dynamic load tests exceeding the Rated Load 6000-18000 KGS. standard. Our adherence to international standards such as ISO 9001:2015 for quality management and ANSI B30.16 for overhead hoists and underhung cranes (which informs our robust design principles for load-bearing equipment) ensures that each unit meets stringent safety and performance benchmarks. This meticulous process contributes to an estimated service life exceeding 10 years under typical industrial usage, minimizing total cost of ownership for our clients.

Versatile Applications and Unmatched Advantages

The adaptability of the Dawei Machinery Mover Straight Type makes it an indispensable tool across a broad spectrum of industries, particularly where heavy, immobile equipment needs to be relocated with precision and minimal effort. Its design for linear movement is especially beneficial in scenarios requiring careful alignment, such as setting up presses in stamping facilities or positioning large generators in power plants. Key application sectors include:

- Petrochemical Industry: For moving heavy distillation columns, heat exchangers, and reactor vessels within processing plants, often in environments requiring anti-corrosion properties.

- Metallurgy & Steel Mills: Facilitating the relocation of massive rolling mills, furnaces, and casting equipment, where extremely heavy loads are routine.

- Power Generation: Transporting turbines, generators, transformers, and other critical infrastructure during installation or maintenance.

- Manufacturing & Assembly: Repositioning large CNC machines, injection molding machines, and production lines for optimized workflow or facility expansion.

- Heavy Construction: Assisting in the precise placement of pre-fabricated structural components or large modular units.

Beyond its sheer load capacity (Rated Load 6000-18000 KGS.), the Dawei Machinery Mover Straight Type offers compelling advantages. Its low friction design significantly contributes to energy efficiency, requiring less force to initiate and maintain movement, which translates into lower operational costs and reduced strain on pulling equipment. The use of high-grade materials and superior manufacturing processes results in excellent durability and longevity, ensuring a low total cost of ownership over its extended service life. The inherent stability provided by its multi-wheel straight configuration minimizes the risk of tip-overs or uncontrolled movements, safeguarding both equipment and personnel. Clients frequently report reduced setup times and increased operational safety after integrating Dawei movers into their logistics chains, highlighting the tangible benefits our engineering brings to the field.

Comparative Edge & Tailored Solutions

In a competitive market, understanding the unique value proposition is key. While many suppliers offer machinery movers, Dawei Hoisting differentiates itself through a blend of superior engineering, stringent quality control, and unparalleled customer service. Unlike some competitors who may compromise on material quality or manufacturing precision to reduce costs, Dawei prioritizes long-term performance and safety. Our load distribution optimization through advanced finite element analysis (FEA) ensures that the stresses are evenly managed across the mover's structure, preventing premature wear and maximizing operational lifespan—a critical factor often overlooked by standard movers.

Furthermore, Dawei Hoisting excels in providing customized solutions. While the standard Dawei Machinery Mover Straight Type caters to a wide range of needs (Rated Load 6000-18000 KGS.), we understand that unique industrial challenges require bespoke approaches. Our engineering team collaborates closely with clients to develop movers with specific dimensions, alternative wheel materials (e.g., steel for extreme temperatures or very rough surfaces), or specialized anti-corrosion coatings tailored for highly aggressive chemical environments. This consultative approach ensures that clients receive not just a product, but a precisely engineered solution that seamlessly integrates into their operational workflow, maximizing efficiency and minimizing custom integration costs. Our decades of experience in the hoisting and material handling industry underscore our authority in delivering reliable and high-performance equipment.

Real-World Impact: Application Cases & Customer Experience

The true measure of a product's value lies in its proven performance in real-world scenarios and the positive feedback from its users. The Dawei Machinery Mover Straight Type has been deployed in numerous challenging industrial settings, consistently delivering exceptional results and earning the trust of our clients. For instance, a major automotive stamping plant utilized our 18000 KGS capacity movers to reconfigure their press lines, reducing the relocation time by 30% compared to previous methods, significantly cutting production downtime.

Another notable case involves a large-scale construction project where our movers facilitated the precise positioning of pre-fabricated concrete modules, each weighing over 10,000 KGS, within confined spaces. The project manager lauded the movers' stability and ease of use, which were critical for maintaining safety standards and adhering to tight deadlines. Our commitment extends beyond product delivery; we provide comprehensive pre-sales consultation and post-sales support, ensuring seamless integration and optimal performance. Our long-standing service record, spanning over two decades in the material handling industry, is a testament to the experience and reliability we bring to every project. Client testimonials frequently highlight our responsive technical support and the long-term durability of our equipment, reinforcing our trustworthiness in the market.

Ensuring Trust: Certifications, Warranty, and Support

Building lasting partnerships in the B2B sector hinges on trust, and at Dawei Hoisting, we underpin this trust with verifiable credentials and robust support systems. Our manufacturing facilities operate under strict ISO 9001:2015 certification, ensuring that every Dawei Machinery Mover Straight Type is produced according to the highest international quality management standards. Furthermore, our products often comply with relevant industry-specific certifications and safety regulations, such as those recommended by the Machinery Directive 2006/42/EC for mechanical equipment, where applicable, reinforcing our product safety and reliability.

We stand behind the quality of our equipment with a comprehensive 1-year limited warranty against manufacturing defects, providing peace of mind to our clients. Our typical delivery period for standard models of the Dawei Machinery Mover Straight Type (Rated Load 6000-18000 KGS.) ranges from 2-4 weeks, depending on order volume and customization requirements, ensuring timely project execution. For urgent needs, expedited options can be discussed with our sales team. Our dedicated customer support team is available to assist with product selection, technical inquiries, and after-sales service, demonstrating our unwavering commitment to client success. We also offer comprehensive documentation and training resources to ensure safe and efficient operation of our machinery movers.

Frequently Asked Questions (FAQ)

-

Q: What is the maximum load capacity of the Dawei Machinery Mover Straight Type?

A: The Dawei Machinery Mover Straight Type is available in models with Rated Load capacities ranging from 6000 KGS up to 18000 KGS, designed to handle a wide array of heavy machinery. -

Q: Can these movers be used on uneven surfaces?

A: While the movers are designed for optimal performance on flat, robust industrial flooring, minor surface irregularities can be navigated. For significantly uneven terrains, additional site preparation or specialized equipment might be recommended. -

Q: What maintenance is required for the Dawei Machinery Movers?

A: The Dawei Machinery Mover Straight Type is designed for minimal maintenance. Regular checks include inspecting wheels for wear, ensuring bearings are free of debris, and cleaning the unit. Detailed maintenance guidelines are provided in the product manual. -

Q: Is customization available for specific applications?

A: Yes, Dawei Hoisting offers extensive customization options for the Dawei Machinery Mover Straight Type, including different load capacities, dimensions, wheel materials, and specialized coatings to meet unique operational demands. Contact our sales team for a consultation.

References

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements.

- American Society of Mechanical Engineers. (2014). ASME B30.16-2014: Overhead Hoists (Underhung).

- European Parliament and Council. (2006). Directive 2006/42/EC on machinery, and amending Directive 95/16/EC.

- Materials Science & Engineering: A. (Various Issues). Publications on advanced alloy steels and polymer composites for heavy-duty applications.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025