Feb . 15, 2025 05:51

Back to list

handheld lifting magnets

Handheld lifting magnets, pivotal tools across various industries, are reshaping how professionals approach the task of lifting and transporting heavy ferrous materials. In warehouse settings, manufacturing plants, and construction sites, these magnet-powered devices serve as indispensable assets, providing an unmatched combination of strength, efficiency, and safety.

Trust in handheld lifting magnets comes not just from their impressive functionality but also from rigorous testing and adherence to safety standards. Quality manufacturers ensure that their products meet or exceed ISO and OSHA standards, providing assurance that these tools can withstand the demanding conditions typical of industrial environments. Whether for everyday use or heavy-duty operations, a reputable handheld lifting magnet is built to endure, reflecting a commitment to performance under pressure and instilling confidence in users. In practice, the benefits of handheld lifting magnets are evident in their contribution to more sustainable and safer work environments. By reducing the dependence on forklifts and cranes for smaller scale lifting tasks, these magnets help decrease energy consumption and carbon footprints. Moreover, they cultivate an atmosphere of safety, where workers are less prone to accidents due to improved lifting ergonomics and lower physical demands. Innovation in handheld lifting magnet technology continues to advance, with companies frequently releasing new models that incorporate features like adjustable magnetic strength and smart technology integration. These developments underscore a dedication to improving user experience and meeting the evolving needs of modern industries, keeping these essential tools at the forefront of material handling solutions. In conclusion, handheld lifting magnets have firmly established themselves as a cornerstone of efficient industrial operations. Their design reflects a deep understanding of user requirements, prioritizing both safety and functionality. Companies that invest in these tools demonstrate a commitment to cutting-edge technology and workplace safety, fostering an environment where human and machine can function harmoniously.

Trust in handheld lifting magnets comes not just from their impressive functionality but also from rigorous testing and adherence to safety standards. Quality manufacturers ensure that their products meet or exceed ISO and OSHA standards, providing assurance that these tools can withstand the demanding conditions typical of industrial environments. Whether for everyday use or heavy-duty operations, a reputable handheld lifting magnet is built to endure, reflecting a commitment to performance under pressure and instilling confidence in users. In practice, the benefits of handheld lifting magnets are evident in their contribution to more sustainable and safer work environments. By reducing the dependence on forklifts and cranes for smaller scale lifting tasks, these magnets help decrease energy consumption and carbon footprints. Moreover, they cultivate an atmosphere of safety, where workers are less prone to accidents due to improved lifting ergonomics and lower physical demands. Innovation in handheld lifting magnet technology continues to advance, with companies frequently releasing new models that incorporate features like adjustable magnetic strength and smart technology integration. These developments underscore a dedication to improving user experience and meeting the evolving needs of modern industries, keeping these essential tools at the forefront of material handling solutions. In conclusion, handheld lifting magnets have firmly established themselves as a cornerstone of efficient industrial operations. Their design reflects a deep understanding of user requirements, prioritizing both safety and functionality. Companies that invest in these tools demonstrate a commitment to cutting-edge technology and workplace safety, fostering an environment where human and machine can function harmoniously.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

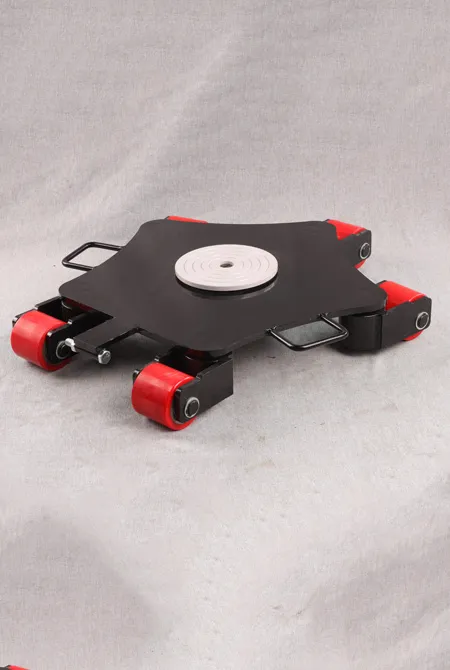

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025