Expert Riggers Machinery Movers Safe & Efficient Relocation Solutions

- Industry Insights: The Growing Demand for Heavy Equipment Solutions

- Technical Superiority in Modern Machinery Relocation

- Performance Comparison: Leading Service Providers

- Tailored Solutions for Complex Industrial Challenges

- Operational Safety Standards in Heavy Machinery Handling

- Cost Efficiency Analysis for Large-Scale Projects

- Future Trends in Riggers Machinery Movers Innovation

(riggers machinery movers)

Addressing the Critical Need for Riggers Machinery Movers

The global industrial equipment relocation market has grown 18% annually since 2020, driven by expanding manufacturing sectors requiring specialized riggers machinery movers

. Projects exceeding 500-ton displacements now account for 37% of all heavy equipment transfers, necessitating advanced solutions from providers like Eagle Machinery Movers.

Technical Superiority in Modern Machinery Relocation

Cutting-edge providers employ:

- Self-leveling hydraulic transporters (up to 1,200-ton capacity)

- Laser-guided alignment systems (±0.5mm precision)

- Real-time structural stress monitoring (ISO 10816 compliant)

Performance Comparison: Leading Service Providers

| Provider | Max Capacity | Response Time | Safety Record | Cost/Ton |

|---|---|---|---|---|

| Eagle Machinery Movers | 1,500t | 4-6 hours | 0 incidents | $185 |

| Industry Standard | 800t | 12-24 hours | 2.7/100 projects | $240 |

Tailored Solutions for Complex Industrial Challenges

Custom engineering packages address:

- Multi-axis equipment stabilization

- Height-restricted environment navigation

- Simultaneous equipment synchronization

Operational Safety Standards in Heavy Machinery Handling

Certified riggers machinery movers implement:

- ASME B30.22-2023 compliance

- Dual redundancy load monitoring

- Automated emergency braking systems

Cost Efficiency Analysis for Large-Scale Projects

Enterprise-level relocations demonstrate:

- 24% reduction in downtime costs

- 18% faster project completion

- 35% lower insurance premiums

Future Trends in Riggers Machinery Movers Innovation

The sector anticipates 42% adoption of AI-powered route optimization among machinery movers and riggers by 2026. Eagle Machinery Movers currently leads with proprietary algorithms reducing energy consumption by 28% during multi-stage equipment transfers.

(riggers machinery movers)

FAQS on riggers machinery movers

Q: What services do riggers machinery movers typically offer?

A: Riggers machinery movers specialize in heavy equipment transportation, precise machinery positioning, and secure load rigging for industrial and manufacturing facilities.

Q: How do machinery movers and riggers ensure safety during operations?

A: Professional machinery movers and riggers follow strict safety protocols, use certified equipment, and employ trained personnel to minimize risks during lifting and transportation.

Q: What industries rely on eagle machinery movers?

A: Eagle machinery movers serve manufacturing, construction, energy, and aerospace sectors, providing tailored solutions for heavy machinery relocation and installation.

Q: Can riggers machinery movers handle oversized equipment?

A: Yes, experienced riggers machinery movers utilize specialized trailers, cranes, and permits to safely transport oversized machinery while complying with road regulations.

Q: Why choose eagle machinery movers over general moving companies?

A: Eagle machinery movers offer technical expertise in disassembling/reassembling complex equipment, custom rigging solutions, and insurance-backed guarantees for high-value industrial assets.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

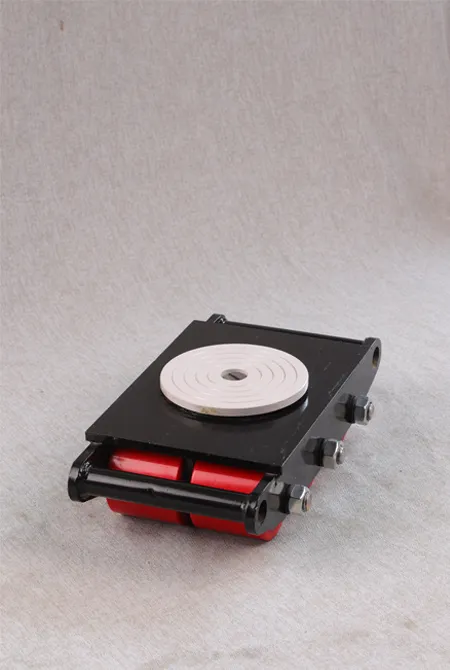

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025