Feb . 15, 2025 00:29

Back to list

magnetic lifting tool

Magnetic lifting tools have revolutionized material handling in various industries due to their efficiency, safety, and reliability. Magnetism, harnessed effectively, enables the seamless handling of ferromagnetic materials, significantly enhancing operational workflows. In industries such as steel manufacturing, automotive, and construction, magnetic lifting devices have become indispensable, offering precise and safe material handling solutions.

One real-world experience highlights the transformative impact of magnetic lifting tools in a steel fabrication plant. Due to their powerful lifting capacity and safety features, the plant optimized its handling processes, resulting in a 30% increase in productivity. Employees reported significantly reduced physical strain, contributing to higher morale and lower absenteeism rates, attesting to the positive change in workplace dynamics. For those considering magnetic lifting tools, the key to building trust and ensuring long-term satisfaction lies in meticulous product selection and maintenance. Regular inspections and maintenance routines should be followed diligently to identify wear and tear, especially in components such as lift chains and hooks. Ensuring that the magnetic surface remains clean enhances its performance and extends its lifespan. Furthermore, engaging in continuous training for operators enhances expertise and safety, aligning with the best industry practices. In conclusion, the adoption of magnetic lifting tools represents a convergence of innovation, efficiency, and safety. Their role in transforming material handling processes is undisputed, offering unmatched advantages in enhancing operational workflows. By prioritizing quality, adhering to safety standards, and committing to regular maintenance, industries can fully leverage the benefits of these tools, ensuring that they remain at the forefront of material handling technology.

One real-world experience highlights the transformative impact of magnetic lifting tools in a steel fabrication plant. Due to their powerful lifting capacity and safety features, the plant optimized its handling processes, resulting in a 30% increase in productivity. Employees reported significantly reduced physical strain, contributing to higher morale and lower absenteeism rates, attesting to the positive change in workplace dynamics. For those considering magnetic lifting tools, the key to building trust and ensuring long-term satisfaction lies in meticulous product selection and maintenance. Regular inspections and maintenance routines should be followed diligently to identify wear and tear, especially in components such as lift chains and hooks. Ensuring that the magnetic surface remains clean enhances its performance and extends its lifespan. Furthermore, engaging in continuous training for operators enhances expertise and safety, aligning with the best industry practices. In conclusion, the adoption of magnetic lifting tools represents a convergence of innovation, efficiency, and safety. Their role in transforming material handling processes is undisputed, offering unmatched advantages in enhancing operational workflows. By prioritizing quality, adhering to safety standards, and committing to regular maintenance, industries can fully leverage the benefits of these tools, ensuring that they remain at the forefront of material handling technology.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

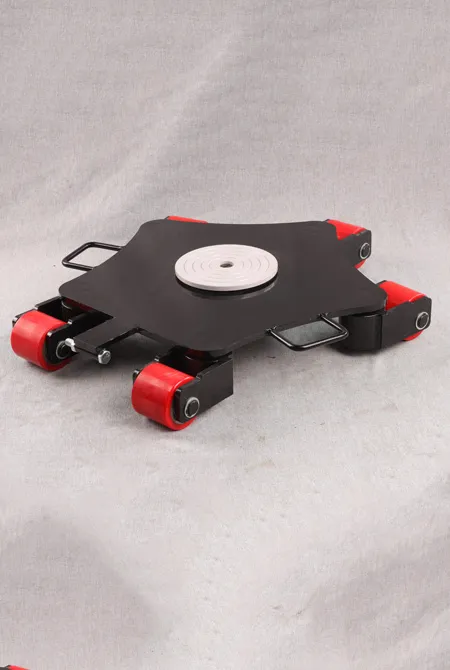

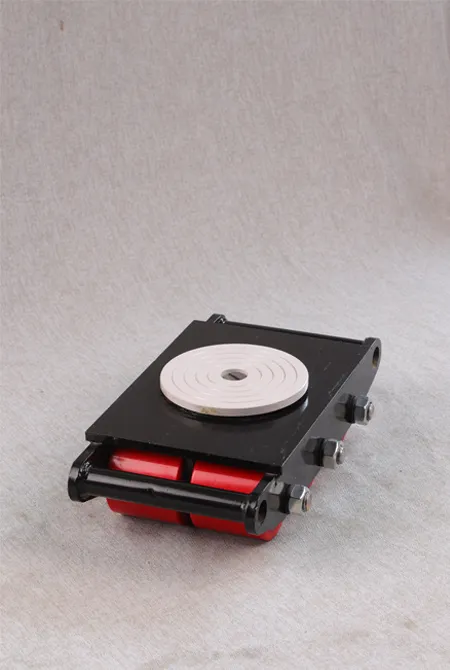

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025