Feb . 15, 2025 01:44

Back to list

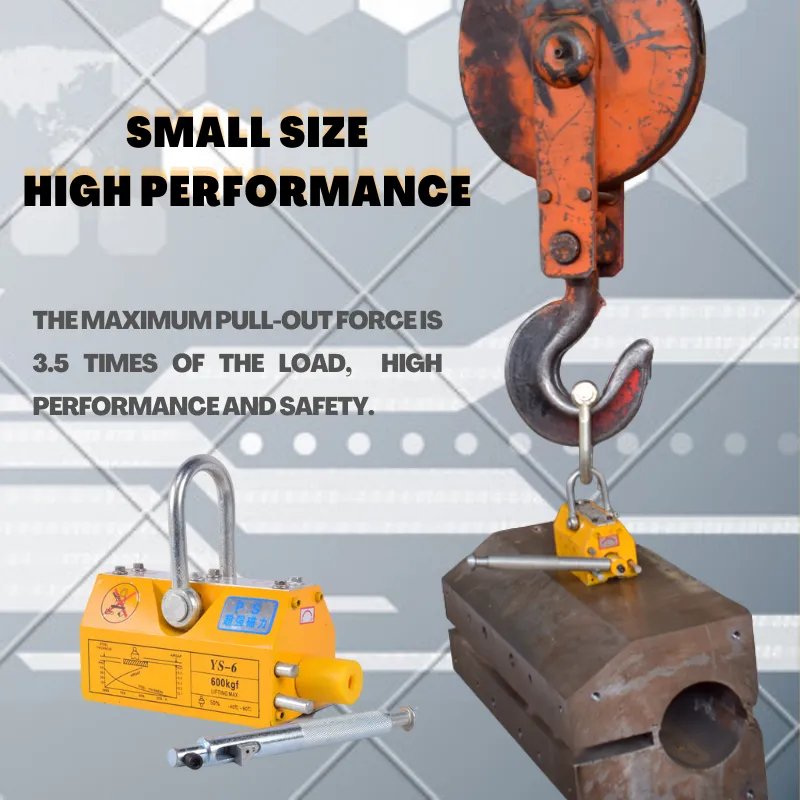

heavy lifting magnets

Heavy lifting magnets are indispensable tools in modern industries, renowned for their ability to efficiently and safely handle large volumes of ferrous materials. These devices are pivotal in manufacturing, construction, scrap yards, and shipbuilding, where precise handling of heavy metal parts is crucial. To understand their significance, one must delve into their real-world applications, expert insights, authoritative recommendations, and why they are trusted by industry leaders.

However, employing heavy lifting magnets requires a fundamental understanding of their operational intricacies to maximize their benefits and ensure safety. Training and certification programs are available for operators to educate them about the magnets' appropriate use and maintenance. This hands-on experience equips professionals with the knowledge to operate the magnets safely, understand load capacities, and implement emergency procedures effectively. Furthermore, routine maintenance of heavy lifting magnets is crucial to ensure long-term performance and safety. Regular inspections, cleaning, and calibration of the magnetic systems can prevent failures and extend the magnet's lifespan, thus providing a better return on investment. Industry experts recommend adhering to a regular maintenance schedule and keeping detailed logs for each magnet. Across the board, businesses that invest in heavy lifting magnets find that these tools not only streamline operations but also save costs on labor and reduce material handling time. Their ability to move large volumes swiftly ensures that businesses remain competitive in the fast-paced industrial landscape. In conclusion, the implementation of heavy lifting magnets is a testimony to how technology can enhance productivity while prioritizing safety. Their use aligns perfectly with modern demands for efficiency, reliability, and safety in material handling. For any industry professional contemplating the adoption of heavy lifting magnets, embracing these tools can lead to transformative improvements in their operational processes, making them an essential investment for future growth and success.

However, employing heavy lifting magnets requires a fundamental understanding of their operational intricacies to maximize their benefits and ensure safety. Training and certification programs are available for operators to educate them about the magnets' appropriate use and maintenance. This hands-on experience equips professionals with the knowledge to operate the magnets safely, understand load capacities, and implement emergency procedures effectively. Furthermore, routine maintenance of heavy lifting magnets is crucial to ensure long-term performance and safety. Regular inspections, cleaning, and calibration of the magnetic systems can prevent failures and extend the magnet's lifespan, thus providing a better return on investment. Industry experts recommend adhering to a regular maintenance schedule and keeping detailed logs for each magnet. Across the board, businesses that invest in heavy lifting magnets find that these tools not only streamline operations but also save costs on labor and reduce material handling time. Their ability to move large volumes swiftly ensures that businesses remain competitive in the fast-paced industrial landscape. In conclusion, the implementation of heavy lifting magnets is a testimony to how technology can enhance productivity while prioritizing safety. Their use aligns perfectly with modern demands for efficiency, reliability, and safety in material handling. For any industry professional contemplating the adoption of heavy lifting magnets, embracing these tools can lead to transformative improvements in their operational processes, making them an essential investment for future growth and success.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025