Feb . 19, 2025 01:18

Back to list

industrial gantry

Industrial gantries, often crucial in large-scale manufacturing and construction environments, have seen evolutionary advancements over the decades. The vast capabilities of these robust structures make them indispensable for many businesses. This article dives deep into their multiple functionalities, expert knowledge surrounding their use, and the trust they inspire within industry professionals.

Authoritativeness is further amplified by industry standards and compliance. Many companies seek gantries that adhere to stringent regulations, such as the American Society of Mechanical Engineers (ASME) or the European Union's Machinery Directive. Certification from recognized bodies ensures that the equipment not only meets safety requirements but also delivers peak operational efficiency. The authoritative nature of certified industrial gantries boosts their attractiveness in competitive markets. Finally, trustworthiness forms the cornerstone of any successful application of industrial gantries. Companies often purchase from manufacturers with a proven track record, evidenced by testimonials and case studies. A trusted manufacturer will openly share past project outcomes, client feedback, and regular performance reviews to instill confidence in potential new clients. Additionally, after-purchase support, such as training, technical assistance, and spare parts availability, plays a crucial role in maintaining this trust. In conclusion, industrial gantries are more than tools; they are enablers of progress and innovation in numerous sectors. Their experienced application, expert engineering, authoritative compliance with standards, and inherent trustworthiness ensure that they remain pivotal to industrial advancement. As industries evolve, gantries will continue to adapt, meeting new challenges head-on and pushing the boundaries of what’s possible in material handling and heavy machinery logistics.

Authoritativeness is further amplified by industry standards and compliance. Many companies seek gantries that adhere to stringent regulations, such as the American Society of Mechanical Engineers (ASME) or the European Union's Machinery Directive. Certification from recognized bodies ensures that the equipment not only meets safety requirements but also delivers peak operational efficiency. The authoritative nature of certified industrial gantries boosts their attractiveness in competitive markets. Finally, trustworthiness forms the cornerstone of any successful application of industrial gantries. Companies often purchase from manufacturers with a proven track record, evidenced by testimonials and case studies. A trusted manufacturer will openly share past project outcomes, client feedback, and regular performance reviews to instill confidence in potential new clients. Additionally, after-purchase support, such as training, technical assistance, and spare parts availability, plays a crucial role in maintaining this trust. In conclusion, industrial gantries are more than tools; they are enablers of progress and innovation in numerous sectors. Their experienced application, expert engineering, authoritative compliance with standards, and inherent trustworthiness ensure that they remain pivotal to industrial advancement. As industries evolve, gantries will continue to adapt, meeting new challenges head-on and pushing the boundaries of what’s possible in material handling and heavy machinery logistics.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

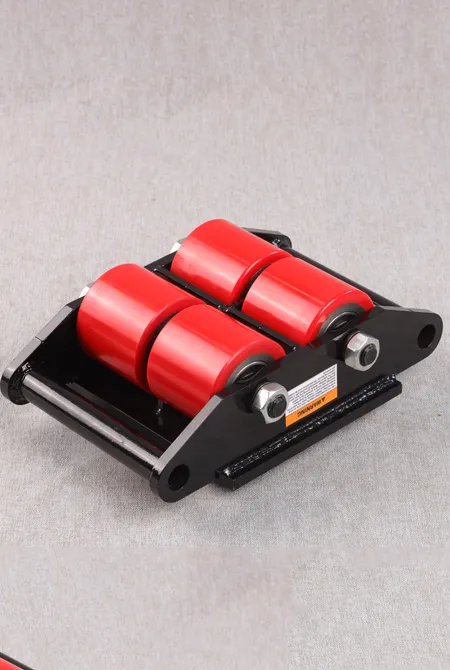

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025