Feb . 14, 2025 07:06

Back to list

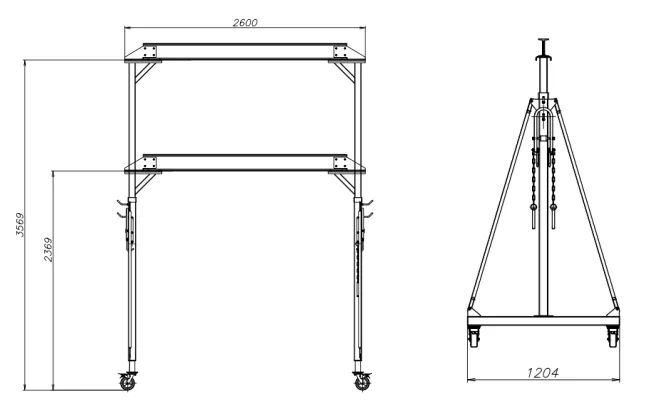

machine moving dollies

Navigating the logistics of moving heavy machinery efficiently and safely is a task of paramount importance in various industries. Among the various equipment available for such tasks, machine moving dollies stand as vital tools that ensure the seamless movement of extremely heavy loads. These robust devices are crucial for industries ranging from construction and manufacturing to warehousing and logistics.

In this context, the expertise behind the manufacture and design of machine moving dollies is paramount. The inclusion of advanced design elements, such as anti-slip platforms, swiveling wheels for enhanced steering, and load-securing straps, embody the product’s expertise—elements born from meticulous engineering and industry feedback. Machine moving dollies also mirror authoritativeness through their compliance with global safety and quality standards. Certifying compliance with entities like the Occupational Safety and Health Administration (OSHA) or European Machinery Directive ensures that these tools meet rigorous safety regulations and offer peace of mind to users and industries alike. Trustworthiness of machine moving dollies underscores their reliable performance record in various industrial applications, backed by user testimonials and long-term use cases. Companies that have turned to these resilient tools have historically experienced notable improvements in logistical operations, supported by empirical evidence highlighting reduced incidence of equipment mishandling and related workplace accidents. In conclusion, the expertise and authority of machine moving dollies find a firm foundation in their design and application within industrial settings. They stand as pillars of trust, ensuring safe, efficient, and effective movement of heavy machinery. As industries increasingly pursue the dual objectives of safety and productivity, these dollies present themselves as indispensable assets. Industry professionals curating forward-thinking logistics solutions must consider integrating state-of-the-art machine moving dollies as part of their strategic approach to machinery handling challenges. Investing in these well-engineered solutions not only facilitates smoother operations but also champions a culture of safety and innovation, propelling industries towards future-ready efficiency and operational excellence.

In this context, the expertise behind the manufacture and design of machine moving dollies is paramount. The inclusion of advanced design elements, such as anti-slip platforms, swiveling wheels for enhanced steering, and load-securing straps, embody the product’s expertise—elements born from meticulous engineering and industry feedback. Machine moving dollies also mirror authoritativeness through their compliance with global safety and quality standards. Certifying compliance with entities like the Occupational Safety and Health Administration (OSHA) or European Machinery Directive ensures that these tools meet rigorous safety regulations and offer peace of mind to users and industries alike. Trustworthiness of machine moving dollies underscores their reliable performance record in various industrial applications, backed by user testimonials and long-term use cases. Companies that have turned to these resilient tools have historically experienced notable improvements in logistical operations, supported by empirical evidence highlighting reduced incidence of equipment mishandling and related workplace accidents. In conclusion, the expertise and authority of machine moving dollies find a firm foundation in their design and application within industrial settings. They stand as pillars of trust, ensuring safe, efficient, and effective movement of heavy machinery. As industries increasingly pursue the dual objectives of safety and productivity, these dollies present themselves as indispensable assets. Industry professionals curating forward-thinking logistics solutions must consider integrating state-of-the-art machine moving dollies as part of their strategic approach to machinery handling challenges. Investing in these well-engineered solutions not only facilitates smoother operations but also champions a culture of safety and innovation, propelling industries towards future-ready efficiency and operational excellence.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025