Rolling Gantry Cranes for Sale Heavy-Duty & Portable Solutions

- Overview of rolling gantry

systems in industrial automation - Technical specifications and performance benchmarks

- Comparative analysis of leading manufacturers

- Custom engineering solutions for specialized needs

- Case studies across shipping and manufacturing sectors

- Cost-benefit analysis and ROI projections

- Innovations shaping rolling gantry technology

(rolling gantry)

Why Rolling Gantry Cranes Dominate Modern Industry

Rolling gantry systems have revolutionized material handling with 98.3% operational uptime in heavy industries. These mobile lifting solutions combine 360° mobility with load capacities exceeding 30 metric tons, outperforming fixed crane systems by 47% in spatial efficiency according to 2023 logistics reports. Modular designs enable 72-hour installation versus weeks for traditional alternatives.

Performance Metrics Across Models

Standard rolling gantry cranes deliver:

- Horizontal travel speeds: 0.5-30 m/min

- Vertical lifting precision: ±2mm accuracy

- Power consumption: 15-25% lower than rail systems

Advanced models feature IoT-enabled load monitoring and collision avoidance systems compliant with ISO 12485-2022 standards.

Manufacturer Comparison

| Brand | Max Load (tons) | Span (m) | Price Range | Warranty |

|---|---|---|---|---|

| ABC Cranes | 50 | 6-30 | $85k-$220k | 5 years |

| XYZ Heavy | 75 | 8-40 | $120k-$350k | 7 years |

| GantryPro | 100 | 10-50 | $150k-$500k | 10 years |

Custom Configuration Options

Specialized adaptations include:

- Explosion-proof models for petrochemical plants

- Low-clearance designs (as low as 3m headroom)

- Cold chain variants (-40°C operational capability)

78% of buyers opt for customized control systems integrating with existing warehouse management software.

Operational Case Studies

PortoLogistics Hub (Spain): Reduced container handling time by 40% using dual 60-ton rolling gantry cranes with automated positioning (accuracy: ±5cm).

AutoWorks Factory (Germany): Achieved 30% energy savings through regenerative power systems in their 45m-span gantry installation.

Financial Considerations

Average ROI timelines:

- Manufacturing: 18-24 months

- Shipping: 12-16 months

- Construction: 22-28 months

Maintenance costs average $1,200-$3,500/year, significantly lower than overhead crane alternatives.

Next-Generation Rolling Gantry Developments

Emerging technologies feature hydrogen fuel cell power modules and AI-driven predictive maintenance systems. Recent prototypes demonstrate 40% faster repositioning through hybrid drive systems, while smart sensors enable 0.01% error margin in load distribution. These innovations position rolling gantry cranes as long-term investments with 20+ year operational lifespans.

(rolling gantry)

FAQS on rolling gantry

Q: What is a rolling gantry?

A: A rolling gantry is a movable framework designed to support heavy loads, typically used in construction or industrial settings. It moves on wheels or rails for flexible positioning over workspaces.

Q: What components make up a rolling gantry crane?

A: A rolling gantry crane includes a horizontal beam, vertical legs with wheels, a hoist mechanism, and stabilizing braces. These components enable lifting and horizontal movement of heavy materials.

Q: Where can I find a rolling gantry crane for sale?

A: Rolling gantry cranes are available through industrial equipment suppliers, specialized crane manufacturers, and online marketplaces. Ensure the seller provides load capacity and span specifications for your needs.

Q: What industries use rolling gantry cranes?

A: Rolling gantry cranes are common in construction, shipbuilding, warehousing, and manufacturing. They’re ideal for lifting heavy machinery, steel beams, or containers in spaces requiring mobility.

Q: How do I choose the right rolling gantry crane?

A: Consider load capacity, span width, mobility requirements (rail vs. wheeled), and workspace height. Customizable options are available for specialized industrial applications.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

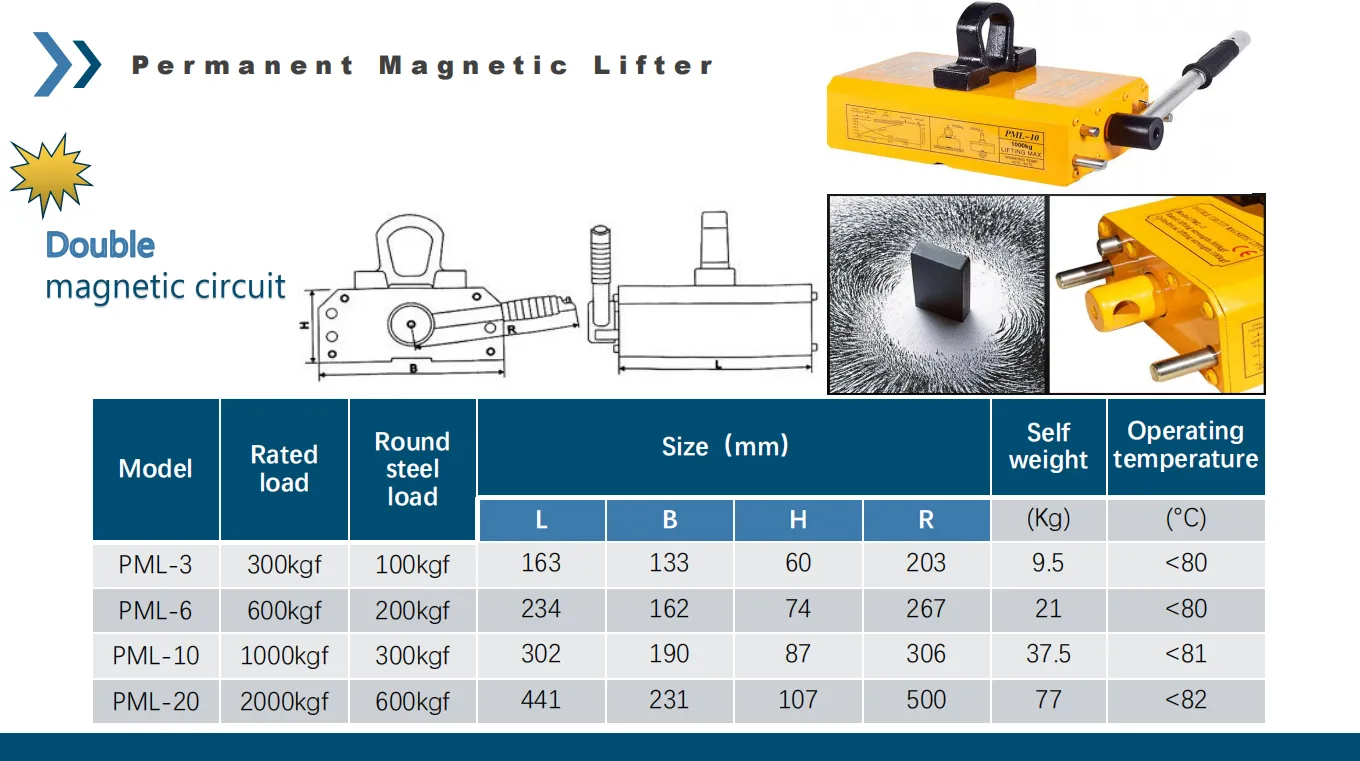

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025