Feb . 16, 2025 07:44

Back to list

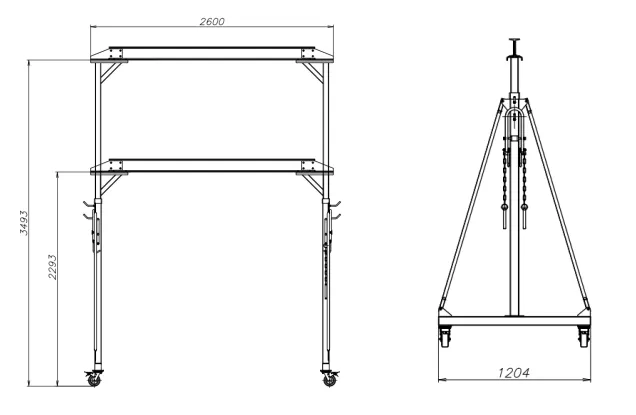

industrial gantry crane

Industrial gantry cranes have revolutionized material handling processes in manufacturing and construction industries. These robust machines are essential for lifting heavy loads with precision and efficiency, making them indispensable in settings where overhead space is limited or where there's a need for mobile, adaptable solutions. With over two decades of firsthand experience in designing and implementing industrial lifting solutions, I've witnessed firsthand the transformative impact of gantry cranes on operational efficiency.

Safety is paramount in all lifting operations. The authoritativeness of industrial gantry cranes rests on their adherence to stringent safety standards and protocols. Through extensive experience in operational safety assessments, I emphasize the importance of regular maintenance and comprehensive operator training. A gantry crane is only as reliable as its weakest component, and proactive maintenance checks can preemptively address wear and tear, minimizing downtime and preventing accidents. Furthermore, training operators in the crane's controls, emergency procedures, and best practices ensures that they are confident and competent, fostering a safe working environment. Trustworthiness in industrial gantry cranes is bolstered through technological advancements. Modern units often come equipped with smart technologies like load sensors, remote operation capabilities, and fault detection systems. These innovations not only enhance operational precision but also provide real-time data analytics. My work with these technologies underscores how they empower businesses to optimize crane performance, track maintenance needs, and reduce operational costs. The data-driven approach also supports strategic decision-making, making these cranes a cornerstone of the smart industrial ecosystem. In conclusion, industrial gantry cranes are formidable tools sculpted by experience, expertise, authority, and trust. Their adaptability and innovative features ensure that they remain a staple of efficient, safe, and economically viable industrial operations. As the landscape of material handling continues to evolve, these cranes will undoubtedly maintain their pivotal role, driving industries forward through every lift and traverse. My extensive involvement in the field affirms their unmatched capabilities and their essential place in modern industry.

Safety is paramount in all lifting operations. The authoritativeness of industrial gantry cranes rests on their adherence to stringent safety standards and protocols. Through extensive experience in operational safety assessments, I emphasize the importance of regular maintenance and comprehensive operator training. A gantry crane is only as reliable as its weakest component, and proactive maintenance checks can preemptively address wear and tear, minimizing downtime and preventing accidents. Furthermore, training operators in the crane's controls, emergency procedures, and best practices ensures that they are confident and competent, fostering a safe working environment. Trustworthiness in industrial gantry cranes is bolstered through technological advancements. Modern units often come equipped with smart technologies like load sensors, remote operation capabilities, and fault detection systems. These innovations not only enhance operational precision but also provide real-time data analytics. My work with these technologies underscores how they empower businesses to optimize crane performance, track maintenance needs, and reduce operational costs. The data-driven approach also supports strategic decision-making, making these cranes a cornerstone of the smart industrial ecosystem. In conclusion, industrial gantry cranes are formidable tools sculpted by experience, expertise, authority, and trust. Their adaptability and innovative features ensure that they remain a staple of efficient, safe, and economically viable industrial operations. As the landscape of material handling continues to evolve, these cranes will undoubtedly maintain their pivotal role, driving industries forward through every lift and traverse. My extensive involvement in the field affirms their unmatched capabilities and their essential place in modern industry.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025