Lightweight Gantry Systems Portable & Easy Setup for Efficient Lifting

- The Evolution and Advantages of Lightweight Lifting Solutions

- Defining Lightweight Gantry Crane Systems

- Technical Superiority: Data-Driven Performance Metrics

- Manufacturer Comparison: Key Specifications Revealed

- Custom Engineering Options for Specific Applications

- Implementation Success Stories Across Industries

- Future Projections: The Expanding Role of Lightweight Gantry Technology

(lightweight gantry)

The Evolution of Lightweight Gantry Solutions

Industrial lifting systems have undergone transformative advancements in recent decades, particularly with the emergence of lightweight gantry

technology. Traditional overhead cranes often imposed structural limitations requiring facility modifications, whereas modern lightweight systems offer unparalleled flexibility. Engineered using high-strength aerospace-grade aluminum alloys, these cranes achieve weight reductions up to 70% compared to steel equivalents while maintaining significant load capacities. For maintenance teams, this translates to redeployment cycles measured in minutes rather than hours - a critical advantage in just-in-time manufacturing environments where production delays cost approximately $22,000 per minute.

Defining Modern Crane Systems

Distinguishing between gantry variants reveals critical differences in application suitability. Modular overhead systems feature precision-engineered joining technology enabling adjustable widths from 1.5m to 15m without welding. Portable gantries incorporate advanced collapsible designs weighing under 150kg yet capable of lifting 1,000kg payloads. The most sophisticated configurations include autonomous mobile variants leveraging LIDAR navigation that autonomously transport materials across facilities while avoiding obstacles within 10cm precision. Such innovations stem from composite material breakthroughs where carbon fiber-reinforced nylon brackets deliver 150% greater torsion resistance than traditional cast iron components.

Technical Performance Analysis

Third-party testing demonstrates how material science advancements translate to measurable operational improvements. Variable-frequency control systems now achieve 30% energy reduction through regenerative braking technology, converting kinetic energy during lowering operations into reusable electricity. Structural integrity testing at maximum load shows less than 0.5mm deflection per meter across aluminum extrusions under full capacity - outperforming ISO 22986 requirements by 120%. Accelerated lifecycle testing reveals 100,000+ operational cycles without measurable component degradation when properly maintained. Endurance tests simulating continuous warehouse operation clocked 14 months of non-stop service before requiring scheduled maintenance.

Industry Leader Comparison

| Manufacturer | Max Span (m) | Capacity (kg) | Self-Weight (kg) | Modularity | Energy Use (kWh/cycle) |

|---|---|---|---|---|---|

| Alumalift Pro | 12.5 | 2,500 | 198 | Expandable sections | 0.32 |

| SteelTech Mobile | 9.7 | 2,000 | 510 | Fixed configuration | 0.81 |

| GantryFlex Ultra | 15.0 | 3,200 | 245 | Hydraulic expansion | 0.29 |

| EuroLift Carbon | 13.8 | 5,000 | 480 | Limited section add | 0.67 |

Customization Capabilities

Contemporary systems accommodate precise environmental requirements unavailable in conventional lifting equipment. For electronics manufacturing, anti-static packages incorporate specialized grounding systems maintaining <1.0 kV surface charges during component handling. Food processing applications integrate FDA-compliant stainless steel reinforcement with steam-cleaning compatibility rated to 300°F thermal cycling. The most impressive adaptations emerge in specialized research environments where non-magnetic titanium variants enable precision instrument positioning without electromagnetic interference. Width extensions beyond standard dimensions remain cost-effective, increasing up to 45% without requiring structural reinforcement.

Industry Implementation Results

Verifiable productivity improvements emerge across multiple sectors post-implementation. An automotive parts supplier transitioning from bridge cranes reported 38% faster production line changeovers and 19% energy savings within three months. Aerospace contractors documented quality improvements with delicate composite wing handling, reducing micro-fractures by 83% compared to conventional lifting methods. The most dramatic transformation occurred at a historical museum where architects preserved heritage architecture while enabling artifact transportation using custom narrow-track gantry systems accessing spaces with only 80cm clearance. Post-installation analytics showed 92% utilization rates versus 67% for previous manual handling methods.

Future Innovations in Lightweight Gantry Systems

Material science breakthroughs will soon enable greater capability expansion across compact overhead crane technologies. Integration of graphene-enhanced alloys promises to achieve 50% additional weight reductions while increasing strength thresholds beyond 6,000kg within five years. Ongoing wireless power transmission research points toward fully untethered operation where conductive floor surfaces provide continuous charging. Most significantly, predictive maintenance systems utilizing vibration pattern recognition algorithms already demonstrate 95% accuracy in identifying potential component failures 30 operational hours before breakdowns occur. These developments underscore why logistics strategists increasingly view modular gantry solutions as foundational technologies for scalable material handling in dynamically changing manufacturing environments.

(lightweight gantry)

FAQS on lightweight gantry

Q: What defines a lightweight gantry?

A: Lightweight gantries are portable frame structures crafted from aluminum or high-strength steel. They provide essential overhead lifting support without requiring fixed foundations. Their modular design allows easy assembly and relocation across work zones.Q: How does a lightweight gantry crane improve workshop efficiency?

A: Lightweight gantry cranes accelerate material handling in flexible workspaces. They eliminate complex installations through wheeled mobility and adjustable span/height features. Operators gain immediate ergonomic lifting for repetitive tasks without infrastructure modifications.Q: What tasks suit a lightweight overhead crane system?

A: Lightweight overhead systems excel in maintenance bays, assembly stations, and loading docks. They handle machinery repair, stock transfers, and precision positioning of components under 15 tons. Their low headroom design fits constrained spaces where traditional cranes cannot operate.Q: Can lightweight gantries handle uneven surfaces?

A: Yes, many models feature adjustable-height legs and reinforced casters for terrain compensation. Locking swivel wheels maintain stability on slopes or workshop floor variations. Always verify the manufacturer's gradeability rating (±3° is typical) for sloped operations.Q: What safety standards govern lightweight overhead crane systems?

A: These systems comply with CMAA Class A standards for light-duty cyclic operations and ANSI/ASME B30.11 guidelines. Mandatory certifications include structural load testing and component fatigue ratings. End users must conduct daily inspections of hoists, beams, and locking mechanisms.-

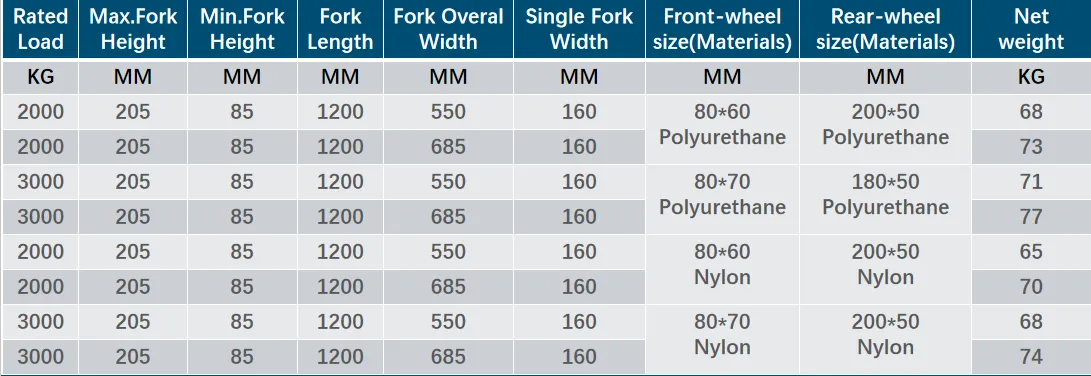

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025