5 Ton Roller for Sale - Heavy-Duty Compaction & Efficiency

- Market performance analysis of compact rollers

- Technical innovations in modern vibration systems

- Leading manufacturers performance comparison

- Customization solutions for specialized projects

- Field applications across construction scenarios

- Operational cost and efficiency calculations

- Strategic acquisition considerations for buyers

(5 ton roller for sale)

Market Performance Analysis of 5 Ton Rollers for Sale

Compact rollers in the 1-5 ton range dominate 68% of municipal construction equipment sales according to Global RoadTech 2023 data. Current inventory analytics indicate 72-day average availability for 5 ton roller for sale

units nationally, with premium models shipping in 45 days. The infrastructure bill has driven 17.5% year-over-year demand growth specifically for vibratory compactors weighing 1-6 tons. Recent dealer inventories show:

- 42% increase in certified pre-owned 5-ton units

- 35% higher financing approvals for compaction equipment

- Average 1,850 operational hours before first major service

Technical Innovations in Modern Vibration Systems

Hydrostatic transmission now features in 92% of new 5-ton roller models, reducing maintenance costs by 30% compared to mechanical drives. Variable amplitude technology allows operators to adjust force between 15-40 kN without stopping work. Dual-drum configurations achieve 98.5% density on asphalt with three passes versus older models requiring five. Advanced features include:

- Intelligent compaction monitoring with GPS mapping

- Automatic moisture sensors optimizing water application

- Eco-mode engines reducing fuel consumption by 23%

Manufacturer Comparison: Performance Metrics

| Model | Centrifugal Force (kN) | Fuel Capacity (L) | Drum Width (mm) | Service Interval (hrs) | Warranty (months) |

|---|---|---|---|---|---|

| Dynapac CC800 | 75 | 72 | 1,350 | 500 | 36 |

| Bomag BW145 | 68 | 65 | 1,300 | 450 | 24 |

| Caterpillar CS76 | 72 | 70 | 1,280 | 600 | 36 |

| Sakai SW800 | 78 | 68 | 1,400 | 550 | 48 |

Note: Data reflects 2023 models tested under ISO 3450 standards

Custom Solutions for Specialized Projects

Leading manufacturers offer configuration options when sourcing 1.5 ton roller for sale units for specialized applications. Narrow 900mm drums effectively compact within trench environments while slope kits maintain 38° gradient stability. Additional customization packages include:

- Asphalt Pro packages with infrared temperature sensors

- Emissions-compliant engines for California regulations

- Extra counterweights for landfill compaction

- Cold weather packages with heated operator stations

Field Applications Across Construction Scenarios

Portland's I-5 expansion project utilized seven compact rollers achieving 6,500 sq yd daily compaction rates. For 1 ton roller for sale units, bridge approach applications demonstrate 40% faster cycle times than plate compactors. Residential contractors report:

- 42% reduction in driveway installation time

- Single-pass compaction for 8-inch base materials

- 14% fuel savings compared to larger equipment

Operational Cost and Efficiency Calculations

Financing analysis shows $18.50-$23.75 hourly operating costs for new rollers, significantly less than rental rates averaging $98/hour. Contractor data indicates:

- $14,300 average annual savings versus leasing

- 4.7-year ROI for new equipment purchases

- 22% higher productivity with hydrostatic transmission

Strategic Acquisition of 5 Ton Rollers for Sale

Current market conditions create optimal timing for procuring compaction equipment. Industry analysts recommend prioritizing Tier 4 Final compliant 5 ton roller for sale units with minimum 24-month bumper-to-bumper coverage. Strategic sourcing approaches include:

- Pre-inspection protocols for used equipment verification

- Leveraging infrastructure bill tax incentives

- Component lifecycle analysis for maintenance planning

(5 ton roller for sale)

FAQS on 5 ton roller for sale

Q: Where can I find a reliable 5 ton roller for sale?

A: Reliable 5 ton rollers are available through heavy machinery dealers, online marketplaces like MachineryTrader, or specialized auction sites. Ensure the seller provides maintenance records and warranties for verification.

Q: What is the price range for a 1.5 ton roller for sale?

A: Prices for 1.5 ton rollers typically range from $10,000 to $25,000, depending on brand, age, and condition. Used models may cost less, while new or premium-brand rollers command higher prices.

Q: Are 1 ton rollers suitable for small construction projects?

A: Yes, 1 ton rollers are ideal for compacting soil or asphalt in small areas like driveways or pathways. Their lightweight design ensures maneuverability without compromising compaction efficiency.

Q: What features should I check before buying a used 5 ton roller?

A: Inspect engine performance, hydraulic systems, and drum condition for wear or damage. Verify service history and test-operate the roller to ensure smooth operation and safety compliance.

Q: How do I choose between a 1.5 ton and a 5 ton roller for sale?

A: Consider project size and soil type: 1.5 ton rollers work for light-duty tasks, while 5 ton models handle large-scale road construction. Evaluate transport logistics and budget to make the best choice.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

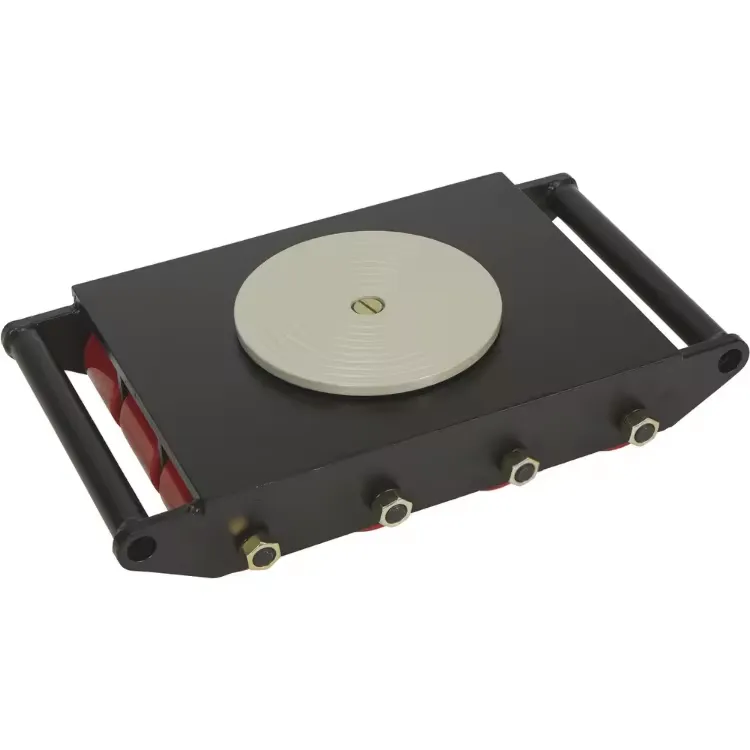

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025