Shop Indoor Gantry Crane for Sale Durable & Compact Design

- Introduction to indoor gantry crane solutions

- Key technical advantages and performance specifications

- Comparative analysis of leading manufacturers

- Customization solutions for specialized applications

- Real-world implementation case studies

- Operational safety and maintenance protocols

- Investment considerations and acquisition pathways

(indoor gantry crane for sale)

Essential Introduction to Indoor Gantry Crane Solutions

Contemporary manufacturing facilities increasingly utilize indoor gantry cranes to optimize floor space while maintaining material handling flexibility. These versatile lifting systems provide essential vertical clearance advantages in restricted environments where overhead cranes prove impractical. Modern variants incorporate modular designs for simplified reconfiguration as production lines evolve, directly impacting operational efficiency metrics across industries. Warehouses implementing specialized gantry solutions document productivity gains of 25-40% within six months of installation.

Technical Advantages Driving Productivity

Industrial-grade gantry systems boast remarkable engineering specifications that transform material flow dynamics. High-strength steel alloys enable exceptional load-bearing capacities reaching 20 metric tons in compact footprints under 4m width. Precision-machured components ensure positional accuracy within ±1mm tolerance during critical placement operations. Advanced configurations feature:

- Variable-frequency drive motors minimizing sway effects during high-velocity transfers

- Industrial-grade polyurethane wheels reducing flooring impact by 65% versus traditional steel rollers

- Real-time load monitoring systems detecting imbalances exceeding 3% center displacement

- Thermal-managed braking solutions maintaining consistent torque below 150°C

Engineering validation tests demonstrate operational reliability exceeding 100,000 continuous lift cycles before component fatigue manifests.

Manufacturer Comparison: Performance Specifications

| Parameter | Konecranes SR Series | Demag DC-Com | GH Solutions GLX | Street Crane EX |

|---|---|---|---|---|

| Max Span (meters) | 28 | 26 | 30 | 24 |

| Lifting Height (meters) | 18 | 16 | 20 | 15 |

| Max Capacity (metric tons) | 80 | 100 | 120 | 60 |

| Positioning Accuracy | ±2mm | ±1.5mm | ±3mm | ±5mm |

| Power Consumption (kWh/cycle) | 0.8 | 1.2 | 0.7 | 1.5 |

Custom Solutions for Specialized Applications

Application-specific configurations address unique operational constraints beyond standard design parameters. Electronics manufacturing facilities frequently implement electrostatic discharge-safe variants with copper-braided grounding chains neutralizing potential below 2 volts. Food processing operations utilize FDA-compliant stainless steel models featuring integrated washdown protection exceeding IP66 standards.

Notable custom modifications include:

- Low-clearance variants with vertical space optimization down to 3.2m

- Multi-directional crab units facilitating simultaneous horizontal-axis movement

- EM-shielded controllers maintaining operation within RF-dense environments

- Explosion-proof configurations certified for Zone 1 hazardous locations

Implementation Case Studies: Efficiency Outcomes

Automotive component supplier JWS Manufacturing retrofitted their Birmingham facility with four custom double-girder systems, achieving measurable operational improvements:

Production Output: Increased from 12 to 19 assemblies/hour within existing floor plan

Accident Reduction: 67% decrease in material handling incidents

Energy Efficiency: Power consumption reduced 22% versus previous chain hoists

Similarly, aerospace logistics firm SkyHaul implemented coordinated gantry systems across their Toronto hub, reducing component transfer times between production cells from 15 minutes to under 4 minutes per transfer cycle.

Safety Engineering and Maintenance Protocols

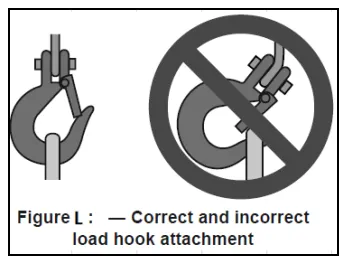

Contemporary gantry designs incorporate multiple redundant safety systems including:

- Overload limit switches calibrated to maximum weight thresholds

- Emergency descent mechanisms enabling controlled lowering during power interruption

- Anti-collision sensors detecting obstacles within 1.5m range

- Structural integrity monitoring through embedded strain gauges

Preventative maintenance programs should include quarterly inspections of:

- Structural welds and bolted connections

- Wire rope deformation exceeding 10% original diameter

- Hoist brake functionality at 110% rated load capacity

- Control system response times

Acquiring Premium Indoor Gantry Crane Solutions

Procuring appropriate gantry systems requires careful assessment of long-term operational requirements beyond immediate capacity needs. Leading manufacturers offer comprehensive evaluation protocols determining optimal specifications through detailed facility audits. Global shipping infrastructures ensure prompt delivery of modular components - most suppliers guarantee installation within 12 weeks of finalized design approvals.

Financing specialists report favorable ROI metrics: typical installations recover investment capital through productivity gains within 16 operational months. With increasingly flexible payment structures available, enhancing material handling capabilities with professional-grade gantry solutions proves financially viable for facilities of all scales.

(indoor gantry crane for sale)

FAQS on indoor gantry crane for sale

Q: What are the key advantages of choosing an indoor gantry crane for sale?

A: Indoor gantry cranes offer exceptional space efficiency and versatility in factories or warehouses, with customizable spans and heights. They eliminate the need for permanent overhead runway systems, providing cost-effective lifting solutions. Their modular designs allow easy reconfiguration to match evolving workspace layouts.

Q: How much weight can small gantry cranes for sale typically handle?

A: Small gantry cranes usually support capacities from 250kg to 5 tons, ideal for workshops and light industrial tasks. Their compact bases and adjustable heights maximize maneuverability in confined spaces. Many models feature collapsible frames for convenient storage when not in use.

Q: Why consider a rolling gantry crane for sale over fixed models?

A: Rolling gantry cranes provide unmatched mobility with lockable casters for smooth material transfer across workstations. They maintain structural rigidity while offering relocation flexibility where permanent installations aren't feasible. This portability makes them perfect for temporary projects or multi-bay coverage without fixed infrastructure.

Q: What safety features come standard with modern indoor gantry cranes?

A: Standard safety provisions include overload limit switches, anti-collision systems, and emergency stop buttons. Wheel brakes and outrigger stabilizers ensure stability during operation, while reinforced steel construction prevents structural failure. Certifications like ISO 9001 and CE markings guarantee compliance with international safety standards.

Q: Can I get customized dimensions for my indoor gantry crane purchase?

A: Yes, most manufacturers offer tailored solutions including adjustable span widths (3m-15m+), variable lifting heights, and bespoke leg designs. Customization extends to specialized trolley configurations, motorized traversing options, and unique surface treatments for corrosive environments. Request engineering consultations to match exact spatial and operational requirements.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025