Efficient Overhead Gantry Systems for Enhanced Productivity in Industrial Environments and Logistics Operations

Understanding Overhead Gantry Systems

Overhead gantry systems are vital components in various industrial applications, widely used for material handling, transportation, and logistics. These systems consist of a framework supported by vertical columns and cross beams, which are equipped with moving hoists or cranes. The design allows for heavy loads to be lifted and transported across a defined space, enhancing efficiency and safety in operations. This article delves into the key aspects, advantages, and applications of overhead gantry systems.

Structure and Functionality

The fundamental structure of an overhead gantry system features a gantry frame that spans across the work area. This rigid framework is typically constructed from steel or aluminum, providing the necessary strength and durability to lift and move heavy objects. Within this frame, hoists, usually operated by electric or manual mechanisms, are installed to raise and lower loads as needed.

The operation of overhead gantry systems can be semi-automated or fully automated, depending on the complexity of the tasks and the needs of the facility. Operators use control interfaces to maneuver the hoists across the gantry’s horizontal beams, allowing for precision in positioning loads. Such flexibility makes overhead gantry systems ideal for various applications in manufacturing, warehouses, and construction sites.

Advantages of Overhead Gantry Systems

The implementation of overhead gantry systems brings numerous advantages to businesses

. Firstly, these systems maximize vertical space utilization, allowing facilities to operate efficiently without the need for extensive floor space. By using the airspace above, companies can conduct operations more effectively, essential in environments where ground space is limited.Secondly, overhead gantry systems enhance safety in the workplace. By mechanizing the lifting and moving processes, these systems minimize the risk of accidents and injuries associated with manual lifting. Operators can control loads from a safe distance, and the machines are designed with safety features like limit switches and emergency stops to prevent mishaps.

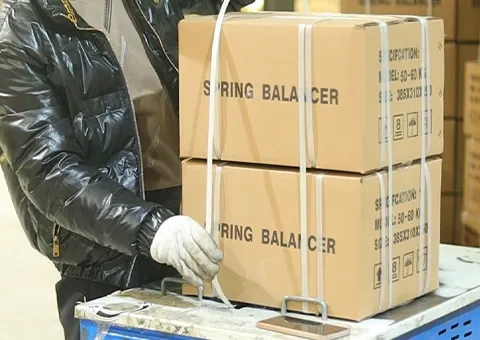

overhead gantry system

Moreover, the efficiency brought by overhead gantry systems can significantly improve productivity. They can handle heavy loads quickly and with minimal manual intervention, reducing downtime during operations. This efficiency translates to faster turnaround times in production and logistics, ultimately benefiting the bottom line.

Applications Across Industries

Overhead gantry systems find applications in a myriad of fields. In manufacturing, they are invaluable for moving components along assembly lines, loading and unloading materials from machines, or transporting products to shipping zones. In warehouses, they assist in storing and retrieving items from shelves, optimizing space and minimizing clutter.

Construction sites also benefit from overhead gantry systems, particularly in lifting heavy building materials such as steel beams and concrete panels. The ability to maneuver loads safely and efficiently is crucial in these environments, where precision is necessary to maintain the integrity of projects.

Additionally, the automotive and aerospace industries employ overhead gantry systems for assembling vehicles and aircraft. These industries often require highly specialized equipment to handle intricate parts, making gantry systems an excellent choice for their versatility and strength.

Conclusion

In summary, overhead gantry systems play a crucial role in modern industrial operations. Their robust design, safety features, and efficient material handling capabilities make them indispensable in a variety of applications. As industries continue to evolve, the adoption of advanced gantry systems will likely increase, paving the way for improved productivity and safety standards in workplaces worldwide. The future of material handling undoubtedly hinges on these powerful machines that enhance operational capabilities across sectors.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025