Efficient Solutions for Moving Heavy Machinery with Professional Mover Skates for Warehouse Use

The Importance of Machinery Mover Skates in Industrial Settings

In industrial settings where heavy machinery and equipment play a crucial role, the movement and relocation of these assets become a significant operational concern. This is where machinery mover skates come into the picture, serving as invaluable tools for effectively and safely moving heavy loads. Their design and functionality offer numerous advantages, making them essential for any organization involved in manufacturing, logistics, or maintenance.

Understanding Machinery Mover Skates

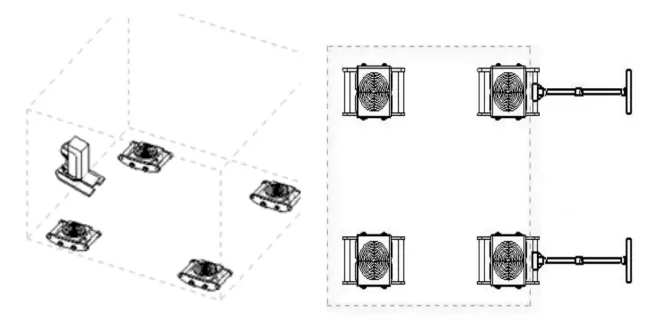

Machinery mover skates are specialized equipment designed to transport heavy machinery and large objects by reducing the friction between the load and the surface below. These skates typically consist of a sturdy frame with wheels that can bear substantial weight. They come in various sizes and designs to accommodate different types of loads, ranging from small machinery to massive industrial equipment.

One of the most notable features of machinery skates is their ability to support heavy weights. High-quality skates can handle loads exceeding several tons, providing stability and safety during transportation. Equipped with swivel wheels, they also offer excellent maneuverability, allowing operators to navigate tight spaces and corners with ease. This flexibility is especially valuable in busy industrial environments where efficient movement is crucial.

Safety First

When dealing with heavy machinery, safety is paramount. The use of machinery mover skates significantly minimizes the risk of accidents and injuries associated with manual handling. These skates help ensure that workers do not strain themselves while trying to lift or move heavy objects, reducing the likelihood of musculoskeletal injuries. Additionally, with the load evenly distributed on the skates, the chance of tipping or rolling incidents decreases, providing a safer working environment.

machinery mover skates

Operators can also use various safety features when employing skates. For instance, some models are equipped with locking mechanisms to secure the load in place during transit, ensuring it does not shift unexpectedly. Furthermore, the use of skates allows for an organized approach to moving equipment, as multiple machines can be relocated simultaneously, thereby optimizing workflow and reducing downtime.

Efficiency and Productivity

Using machinery mover skates not only enhances safety but also improves efficiency. Traditional methods of moving heavy loads often require multiple workers, cranes, or forklifts, which can be time-consuming and costly. In contrast, skates streamline the process, allowing a single operator to move machines with remarkable ease. This efficiency translates into higher productivity, as tasks can be completed faster with fewer disruptions to the workflow.

Moreover, the use of skates reduces the wear and tear on flooring. Heavy equipment rolling directly over surfaces can lead to damage or wear, necessitating costly repairs. By using skates, companies can protect their infrastructure and reduce maintenance costs over time.

Conclusion

In conclusion, machinery mover skates play a vital role in the effective management of heavy machinery within industrial environments. Their design promotes safety, enhances efficiency, and protects facility infrastructure, making them indispensable tools for any organization dealing with substantial workloads. By investing in high-quality machinery mover skates, companies can streamline operations, safeguard their workers, and ultimately improve their bottom line. As industries evolve and demand for heavy machinery continues to grow, the importance of these tools will undoubtedly increase, emphasizing the need for effective solutions in material handling processes. Whether in manufacturing, warehousing, or maintenance operations, machinery mover skates represent a simple yet powerful solution to one of the industry's most pressing challenges.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025