Efficient Strategies for Industrial Equipment Relocation and Setup Management

Industrial Equipment Relocation Challenges and Solutions

Relocating industrial equipment is a significant and often complex task that businesses face when they undergo expansion, downsizing, or operational optimization. This process, which involves moving heavy machinery, tools, and other essential equipment from one location to another, can present numerous challenges. Understanding these challenges and how to tackle them is crucial for ensuring a smooth relocation and minimizing downtime.

One of the primary challenges of industrial equipment relocation is the logistics involved in the planning and execution of the move. Often, heavy machinery is custom-built for specific tasks and dimensions, making dismantling and reassembly a meticulous process. Businesses need to develop a detailed inventory of all equipment, capture the layout of the current facility, and determine how best to disassemble each piece of machinery. Mapping out the new location is equally essential; businesses must consider the layout, accessibility, and space required for each piece of equipment to operate efficiently.

Safety is another critical concern during the relocation of industrial equipment. Heavy machinery poses significant risks to workers if not handled correctly. Employers are responsible for ensuring that all safety protocols are followed, which may include training personnel on proper lifting techniques, using appropriate equipment, and adhering to best practices for transporting heavy items. This need for safety can complicate the timeline of the move, as additional training and precautions may extend the relocation process.

The financial implications of relocating industrial equipment cannot be overlooked. The costs associated with transportation, labor, and downtime can accumulate quickly, impacting a company's bottom line. Businesses must budget for both visible costs, like transportation fees, and hidden costs, such as delays in production and potential damage to equipment during the move. Proper planning and risk assessment can help mitigate these expenses, but there will always be unforeseen circumstances that can arise, further complicating the financial aspect of relocation.

industrial equipment relocation

To navigate these challenges effectively, it is often beneficial for companies to engage professionals specialized in industrial equipment relocation. These experts can bring valuable experience and resources that assist in planning and executing the move while reducing risks. They can provide insights into equipment handling, logistics management, and compliance with regulations. Working with professionals can also alleviate some of the burdens on internal staff, allowing them to focus on their core responsibilities.

Another aspect that companies must consider is the timeline for the relocation process. An extended downtime can lead to production losses and impact customer relationships. To minimize downtime, organizations should strive to conduct a thorough assessment prior to the move, allowing them to create a timeline that accommodates disassembly, transport, and reassembly. Efficient planning can reduce the time machinery remains offline, enabling businesses to resume operations as quickly as possible.

Communication plays a vital role in successful industrial equipment relocation. Ensuring that all stakeholders, including employees, management, vendors, and contractors, are on the same page regarding the relocation plan will foster collaboration and responsiveness. Regular updates and progress reports can help keep everyone informed about the status of the move and allow for the swift resolution of any issues that may arise.

In conclusion, industrial equipment relocation is a multifaceted process that requires careful consideration of various factors, including logistics, safety, costs, and timelines. By anticipating the challenges involved and employing best practices in planning and execution, businesses can execute a successful relocation that minimizes downtime and maximizes operational efficiency. Engaging industry professionals can further enhance the process, ensuring that all aspects are managed effectively while allowing company personnel to maintain focus on their everyday operations. With the right strategies in place, companies can navigate the complexities of industrial equipment relocation and emerge stronger and more efficient in their new operational settings.

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

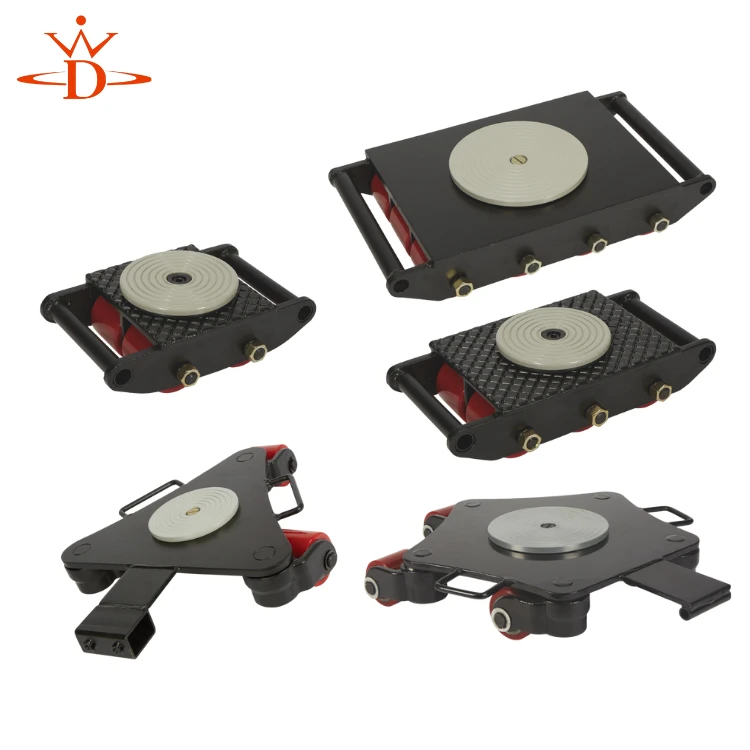

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025

-

Efficient Relocation Starts with Reliable Machinery MoversNewsAug.29,2025