Innovative Permanent Lifting Magnets Featuring Convenient On-Off Control Mechanism for Enhanced Efficiency

The Innovation of Permanent Lifting Magnets with On/Off Control

In the industrial world, efficient material handling plays a crucial role in maximizing productivity. Among the various equipment used for lifting heavy objects, permanent lifting magnets have gained significant attention due to their simplicity and effectiveness. The recent advancements in technology have introduced a new feature on/off control, which enhances both utility and safety in lifting operations.

Understanding Permanent Lifting Magnets

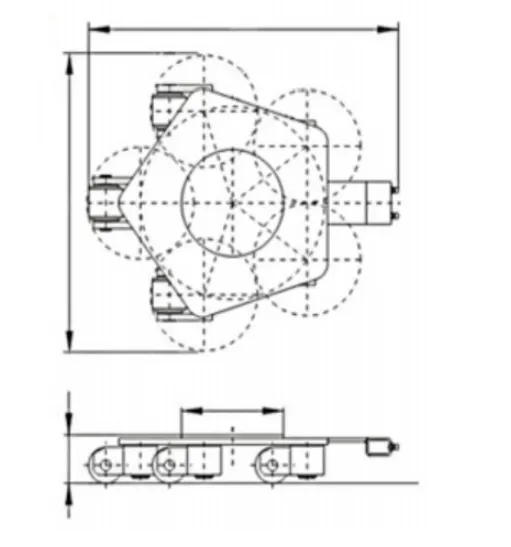

Permanent lifting magnets are devices that utilize the magnetic force produced by permanent magnets to lift ferromagnetic materials. Unlike electromagnets, which require a continuous power supply, permanent magnets maintain their magnetic field without electrical energy, making them energy efficient and environmentally friendly. The key components of these magnets include high-performance magnetic materials that create a strong and stable field capable of lifting substantial loads.

The Advantages of On/Off Control

The introduction of on/off control in permanent lifting magnets marks a substantial leap in their functionality. This feature allows operators to easily engage or disengage the magnetic field with the simple flip of a switch. The benefits of this innovation are manifold

1. Improved Safety One of the critical concerns in any lifting operation is safety. With on/off control, operators can ensure that the magnet is only active during the lifting process. This significantly reduces the risk of accidents caused by accidental magnetization, which can lead to materials being unintentionally lifted or dropped.

permanent lifting magnets with on off control

2. Enhanced Efficiency The ability to turn the magnet on or off means that operators can manage their workflow more efficiently. They can lift and lower loads as needed without the hassle of managing electrical connections or worrying about power supply interruptions. This streamlines the material handling process, resulting in faster turnaround times in industries like manufacturing, construction, and shipping.

3. Energy Cost Savings Since permanent magnets do not require power to maintain their magnetic field, the on/off control feature allows for further energy savings. When the magnet is not in use, it can be turned off, minimizing any unnecessary wear and tear on equipment and ensuring a longer lifespan for both the magnets and related machinery.

4. Versatile Applications The flexibility of on/off control opens new avenues for applications across various industries. From warehouse operations to scrap yards, these advanced lifting magnets can be adapted to a variety of tasks, including loading and unloading materials, handling large beams, or organizing heavy equipment.

5. Ease of Use Modern designs of permanent lifting magnets with on/off capabilities come with user-friendly controls, making them accessible for operators of all skill levels. This ease of use encourages more widespread adoption within the industry and minimizes the necessary training time for new personnel.

Conclusion

As industries continue to evolve and demand for more efficient material handling solutions grows, the adoption of permanent lifting magnets with on/off control is expected to rise. These tools not only enhance safety and efficiency but also contribute to significant cost savings and operational versatility. As technology advances, we can anticipate further innovations that will refine these systems, ensuring they remain an integral part of the material handling arsenal in modern operations. In essence, the integration of on/off control in permanent lifting magnets represents a significant step forward, embodying the principles of safety, efficiency, and adaptability that define the future of industrial processes.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025