lifting magnet 100kg

The Power and Versatility of Lifting Magnets A Focus on the 100 kg Model

In modern industrial applications, lifting magnets have become an essential tool for moving heavy metal objects with ease and efficiency. Among various options available in the market, the 100 kg lifting magnet stands out due to its blend of power, reliability, and versatility. This article explores the features, benefits, applications, and safety measures associated with 100 kg lifting magnets.

Understanding Lifting Magnets

Lifting magnets are electromagnetic devices designed to lift ferromagnetic materials, such as steel, iron, and other similar metals. Unlike traditional lifting equipment, such as cranes and hoists, lifting magnets utilize magnetic fields to attach themselves securely to objects, offering a seamless lifting operation without the need for slings, chains, or hooks.

The basic working principle of lifting magnets revolves around electromagnetism. When an electric current passes through the coil of the magnet, it generates a magnetic field, allowing it to attract and hold ferromagnetic materials. Once the current is cut, the magnetic force is eliminated, releasing the object. This on-off capability provides significant operational advantages, especially in environments where quick, repeated lifts are required.

Features of the 100 kg Lifting Magnet

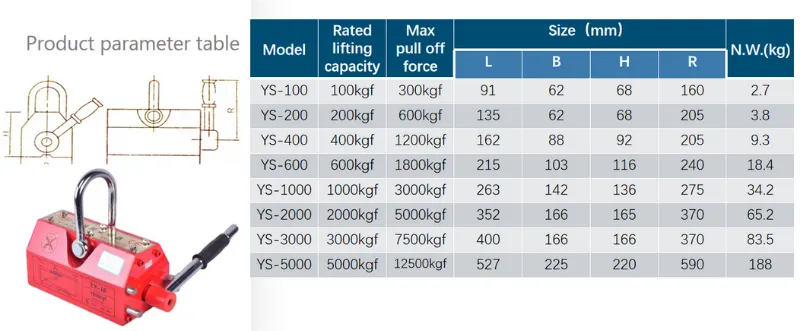

The 100 kg lifting magnet is engineered to handle loads up to 100 kilograms, making it suitable for a wide range of applications in manufacturing, warehousing, and construction. It typically includes features such as

1. Robust Construction Made from high-quality steel and durable components, ensuring longevity even in rugged working environments. 2. Powerful Lifting Capacity Capable of lifting up to 100 kg safely and efficiently, allowing for the handling of medium-sized ferromagnetic items.

3. Easy Operation Most models are designed for easy activation and deactivation, often featuring a simple switch or lever which can be controlled with one hand.

4. Portability Many 100 kg lifting magnets are lightweight and portable, making them easy to transport and use in various locations.

5. Versatile Applicability Works well with flat, round, and irregularly shaped ferromagnetic materials, broadening its range of applications.

Applications of 100 kg Lifting Magnets

The versatility of 100 kg lifting magnets makes them suitable for various industries. Common applications include

- Manufacturing Used to move components such as metal sheets, rods, and blocks from one location to another, enhancing workflow efficiency

.lifting magnet 100kg

- Construction Ideal for lifting and repositioning heavy steel beams or reinforcing bars in construction sites, thereby accelerating project timelines.

- Warehousing Facilitates the quick loading and unloading of metal products, improving warehouse operations.

- Metal Recycling Useful in recycling facilities for separating ferrous metals from non-ferrous materials, contributing to more efficient recycling processes.

- Shipbuilding Employed in shipyards for transporting heavy metal parts and structures, ensuring safe and manageable operations.

Safety Considerations

While lifting magnets offer numerous advantages, safety should always remain a priority. Operators should adhere to the following safety measures

1. Weight Capacity Never exceed the maximum lifting capacity of 100 kg as indicated by the manufacturer to prevent accidents or equipment failure.

2. Inspection and Maintenance Regularly inspect the lifting magnet for any signs of wear or damage. Scheduled maintenance can help ensure optimal performance.

3. Surface Cleanliness Ensure that the surface of the load is clean and free from rust or debris, which can impact the magnetic grip quality.

4. Training Operators should receive thorough training on the proper use of lifting magnets, including emergency procedures in case of power failure.

5. Personal Protective Equipment (PPE) Utilize appropriate PPE, including gloves, safety glasses, and steel-toed boots, to protect against potential hazards.

Conclusion

The 100 kg lifting magnet exemplifies the advancements in material handling technology, providing industries with a powerful, efficient, and versatile solution for lifting ferromagnetic materials. By understanding its features and applications, and by adhering to safety protocols, users can maximize the benefits of this innovative tool, ultimately enhancing productivity and safety in various environments. Whether in manufacturing, construction, or recycling, the 100 kg lifting magnet remains an indispensable asset for modern operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025