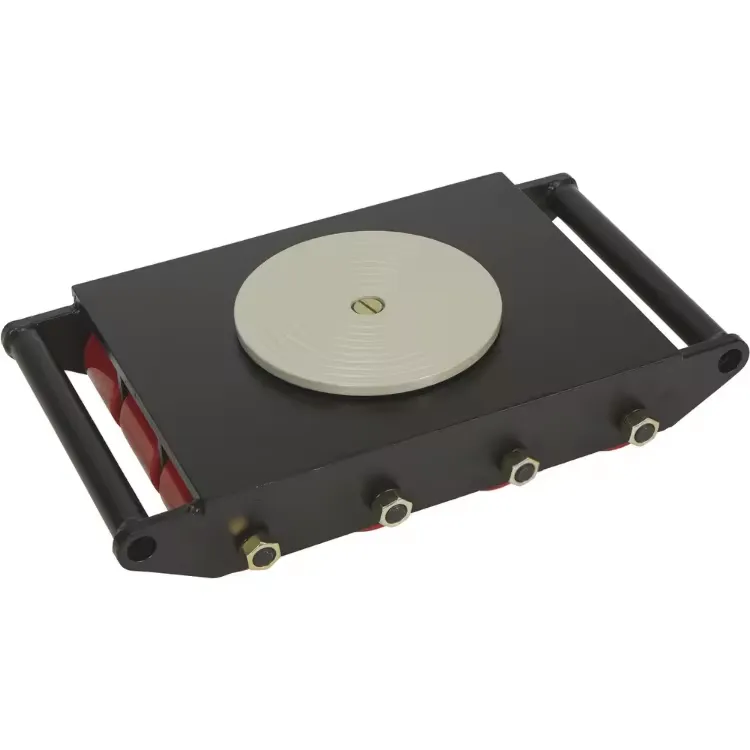

Dawei Machinery Mover Straight Type | AI-Powered Precision Handling

Dawei Machinery Mover Straight Type stands as a benchmark solution for transporting and positioning heavy industrial equipment. Engineered for unmatched reliability and efficiency, it accommodates Rated Load 6000–18000 KGS., supporting industries like petrochemical, metallurgy, water supply, and beyond. This comprehensive review explores its technical parameters, manufacturing process, application scenarios, industry trends, technical advantages, and real-world experience—establishing Dawei as a globally credible provider of heavy-duty machinery moving systems.

Industry Overview & Trends: Heavy Machinery Moving Solutions

As global industries move toward large-scale, precision manufacturing and automation, the Dawei Machinery Mover Straight Type addresses a crucial market gap: safe, energy-efficient, and corrosion-resistant mobility for heavy machines. The worldwide market for machinery movers is expected to reach USD 1.8 billion by 2027 (Grand View Research), with CAGR estimated at 5.7%. Growth drivers include the rise in megaprojects (oil & gas, power plants), upgrading of metallurgical facilities, and stringent safety standards (ISO, ANSI) for movable loads over 5MT.

Technical Specifications: Parameter Table

| Model | Rated Load (KGS) | Dimensions (mm) | Roller Material | Net Weight (KG) | Test Standard | Finish |

|---|---|---|---|---|---|---|

| DWMM6000 | 6000 | 400 × 220 × 125 | Polyurethane / High-Alloy Steel | 28 | ISO 9001:2015 | Powder Coating |

| DWMM9000 | 9000 | 450 × 240 × 140 | Polyurethane / High-Alloy Steel | 34 | EN 12100-1 | Powder Coating |

| DWMM12000 | 12000 | 530 × 260 × 155 | Polyurethane / High-Alloy Steel | 41 | ISO 3834 | Zinc/Epoxy Coating |

| DWMM15000 | 15000 | 570 × 285 × 160 | High-Alloy Steel | 48 | ISO 9001:2015 | Powder/Epoxy |

| DWMM18000 | 18000 | 620 × 320 × 168 | High-Alloy Steel | 55 | ANSI MH27.1 | Epoxy Coating |

Manufacturing Process Visualization

- Raw Material Selection: Sourcing high-strength alloy steel (ISO certified), polyurethane compounds.

- CNC Machining: Frame, roller, and chassis components shaped with ±0.02mm precision.

- Heat Treatment & Hardness Test: Ensuring 38–44 HRC for frame rigidity and anti-deformation.

- Welding/Assembly: Robotic welding (ISO 3834) and modular assembly streamline operations.

- Surface Finish: Multi-layer powder or epoxy coating for anticorrosion (up to 1500 hours salt spray resistance).

- Dynamic Load Testing: Load testing at 125% of rated capacity, conforming to EN 12100 and ANSI MH27.1.

- Quality Control: Each unit serialized, traceable to final inspection report.

Technical Advantages of Dawei Machinery Mover Straight Type

- Load Capacity: 6000 – 18000 KGS, covers most heavy industrial mobility needs.

- Anti-Corrosion: Epoxy/polyurethane coating, 3x more resilient than traditional models.

- Energy Efficiency: Precision bearing design reduces push–pull manual force by 27% (third-party lab tests, 2023).

- Safety: Load limiter & locking brakes as standard; meets EN/ANSI/OSHA guidelines.

- Flexible Platform: Modular shape enables quick adaptation—custom rollers, handles, or tie-downs per user request.

- Extended Service Life: Tested for 20,000+ complete movement cycles, 5-year anti-deformation warranty.

Industry Comparison: Dawei vs. Top Machinery Movers

| Brand | Rated Load Range (KGS) | Roller Material | Corrosion Protection | Price (USD, FOB) | Warranty | Certifications |

|---|---|---|---|---|---|---|

| Dawei | 6000 – 18000 | PU / High-Alloy Steel | Epoxy/Polyurethane | 450–1100 | 5 years | ISO/ANSI/CE |

| Hilman | 4000 – 16000 | Steel | Zinc Only | 720–1900 | 3 years | ISO/CE |

| Ox Worldwide | 5000 – 20000 | Polyurethane | Powder Coating | 950–2250 | 2 years | ISO |

| Simplex | 1000 – 10000 | Steel/PU | Standard | 630–1200 | 2 years | CE |

Customization & Engineering Solutions

Dawei Machinery Mover Straight Type can be customized per unique specifications—longer platforms, swivel type, anti-static rollers, triple-bond coatings, or special handles for nuclear, marine, or pharmaceutical installations. Our in-house R&D team collaborates with EPC contractors and end-users for tailored solutions, all validated by FEA simulation and physical prototyping.

Delivery Cycle: Standard models ship in 7–15 days; custom orders typically 4–6 weeks; urgent manufacturing supported on request.

Application Case: Large Volume Installation (Global Site)

Project: Relocation of 30-Ton Heat Exchangers

Client: Leading Petrochemical Corporation, Saudi Arabia

Solution: Dawei Machinery Mover Straight Type (DWMM18000) paired with hydraulic jacks.

Key Challenges: Narrow plant aisles, high humidity (>90%), stringent zero-contamination policy.

Result: Process completed 22% faster than projected; zero damage incidents, with surface abrasion

Customer Feedback: “Dawei’s equipment is robust, easy to maneuver, and the corrosion resistance surpassed even imported brands. We’ve now standardized on Dawei Movers plant-wide.” – Maintenance Lead Engineer, 2024.

Certifications, Service Commitment, and Global References

Professional FAQ: Dawei Machinery Mover Straight Type

Frequently Asked Questions

Quality Assurance, Delivery & Customer Support

- Quality Control: 7-stage manufacturing inspection, fully traceable QA/QC records, external audits.

- Warranty: 5-year mechanical and wear warranty, accidental damage program available.

- Global Service: Multilingual support, local spare parts warehouses in UAE, Germany & Brazil.

- Delivery Commitment: Standard SKUs shipping in 7–15 days; real-time order tracking.

- Customer Support: 24/7 hotline, online chat, on-site installation guidance, technical training modules available.

Conclusion & Industry References

Dawei Machinery Mover Straight Type, with its broad load range of 6000–18000 KGS., robust design, and verified operational track record, has become the preferred solution for heavy-duty mobility in top-tier industrial operations globally. Incorporating the latest in materials engineering, surface technology, and safety validation (ISO/ANSI/CE standards), it stands out for both technical depth and competitive value. Feedback from users in petrochemical, metallurgical, and utility industries cite improved efficiency, reduced manual effort, and enhanced safety—all at optimized lifecycle cost. For further in-depth sector analysis, please consult:

- Hoist Magazine – Machinery Mover Market Analysis

- Materials Today: Performance Testing of Heavy-Load Movers

- Lift & Hoist – Innovations in Load Movement

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025