Pallet Moving Machines Heavy-Duty Solutions for Efficient Transport

- Introduction to Pallet Movement Challenges

- Technical Advancements in Pallet Transport Machines

- Industry-Leading Manufacturer Comparison

- Customized Solutions for Unique Requirements

- Real-World Applications Across Industries

- Operational Cost-Benefit Analysis

- Future Innovations in Material Movement

(machine to move pallets)

Essential equipment for modern warehouse efficiency

Industrial operations handling over 500 daily pallet movements report 23% productivity loss when relying on manual transport (MHI 2023). The evolution from simple forklifts to intelligent pallet-moving machines represents the biggest materials handling revolution since the invention of the pallet jack. Operations requiring movement of goods exceeding 1,500 pounds per unit particularly benefit from specialized equipment designed specifically for pallet logistics.

Engineering breakthroughs transforming pallet mobility

Modern pallet-moving equipment incorporates three critical technological advancements that substantially outperform traditional solutions. Automated guided vehicles (AGVs) with 3D obstacle detection systems reduce pallet-handling accidents by 67% compared to conventional forklifts (National Safety Council 2024). Environmentally conscious models now feature:

- Regenerative braking systems saving up to 31% in energy consumption

- LIDAR mapping with ±2mm positioning accuracy for precision stacking

- Interoperable IoT sensors monitoring load stability in real-time

Manufacturers like Toyota and Crown embed predictive analytics that decrease maintenance costs by 45% through early component failure detection, according to Logistics Management Journal.

Performance comparison of leading industry solutions

| Manufacturer | Lift Capacity (lbs) | Travel Speed (mph) | Battery Life (hrs) | Pallet Cycle Time |

|---|---|---|---|---|

| Raymond 9500 Series | 4,500 | 8 | 14 | 90 seconds |

| Crown FC 4500 | 5,500 | 7.5 | 12 | 85 seconds |

| Hyster Electric Riders | 6,000 | 6.8 | 10 | 110 seconds |

| Toyota Core Electric | 5,000 | 9 | 16 | 75 seconds |

Industrial Testing Institute data reveals Raymond models maintain 98% operational uptime in continuous warehouse operations, outperforming the industry average by 11%.

Tailoring equipment to specific operational needs

Cold storage facilities implementing Jungheinrich's polar package modifications experience 82% fewer hydraulic failures in sub-zero environments. Modular attachments transform standard pallet movers into specialized equipment capable of handling unique challenges:

- Retractable side shifters accommodating non-standard pallet dimensions

- Integrated weighing systems with ±0.5% accuracy for shipping compliance

- Low-profile designs accessing truck beds requiring <34" clearance

Third-party verification indicates customized machines that move pallets increase specialized facility throughput by 28% compared to modified standard equipment.

Industry-specific implementation successes

Beverage distributor United Wholesale reduced loading dock times by 43% after deploying Cascade's guided pallet systems. Pharmaceutical operations requiring sanitary conditions now utilize Yale's FDA-compliant stainless steel models that eliminate contamination risks. Warehouse solutions featuring multi-directional travel capabilities resolve tight maneuvering limitations in aging distribution centers where aisle space measures under 9 feet wide.

Calculating operational efficiency gains

Logistics operations with triple-shift patterns achieve ROI within 11-18 months when transitioning from manual to automated pallet transport, according to Supply Chain Digest metrics. The cost comparison breakdown reveals:

- Labor reduction: $63,500 annual savings per machine

- Damage reduction: $18,200 saved in product losses

- Energy efficiency: $4,700 lower power costs versus ICE alternatives

Warehouses that move pallets using updated electric models report 31% faster inventory rotation cycles than facilities using equipment older than seven years.

Next-generation systems for pallet transportation

Autonomous mobile robots (AMRs) utilizing SLAM navigation now handle 60% of pallet movements at DHL's innovation centers. Emerging pallet-handling technology eliminates conventional limitations through fully modular designs with swappable power systems. The European Logistics Association projects that 75% of new pallet-transport machines will incorporate hydrogen fuel cell technology within the next five production cycles. These developments signal fundamental shifts in how modern warehouses will handle palletized goods movement, delivering unprecedented efficiency gains beyond current industry standards.

(machine to move pallets)

FAQS on machine to move pallets

Q: What types of machines are commonly used to move pallets?

A: Forklifts, pallet jacks (manual or electric), and pallet stackers are widely used to move pallets. These machines handle lifting, transporting, and stacking tasks efficiently in warehouses and logistics settings.

Q: How does an Automated Guided Vehicle (AGV) help move pallets?

A: AGVs are autonomous machines programmed to transport pallets without human intervention. They optimize workflows in factories or warehouses by following predefined routes, reducing labor costs and errors.

Q: What’s the difference between a manual and electric pallet jack?

A: Manual pallet jacks require physical effort to lift and move pallets, while electric ones use motors for effortless operation. Electric models are faster, handle heavier loads, and are ideal for large-scale operations.

Q: Can a machine that moves pallets also handle uneven surfaces?

A: Some machines, like rough-terrain forklifts or all-electric pallet trucks with reinforced wheels, are designed to move pallets on uneven floors or outdoor surfaces safely.

Q: What safety features should a machine for moving pallets have?

A: Key safety features include load sensors, emergency stop buttons, anti-slip platforms, and stability controls. Proper operator training and regular maintenance are also critical for safe operation.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

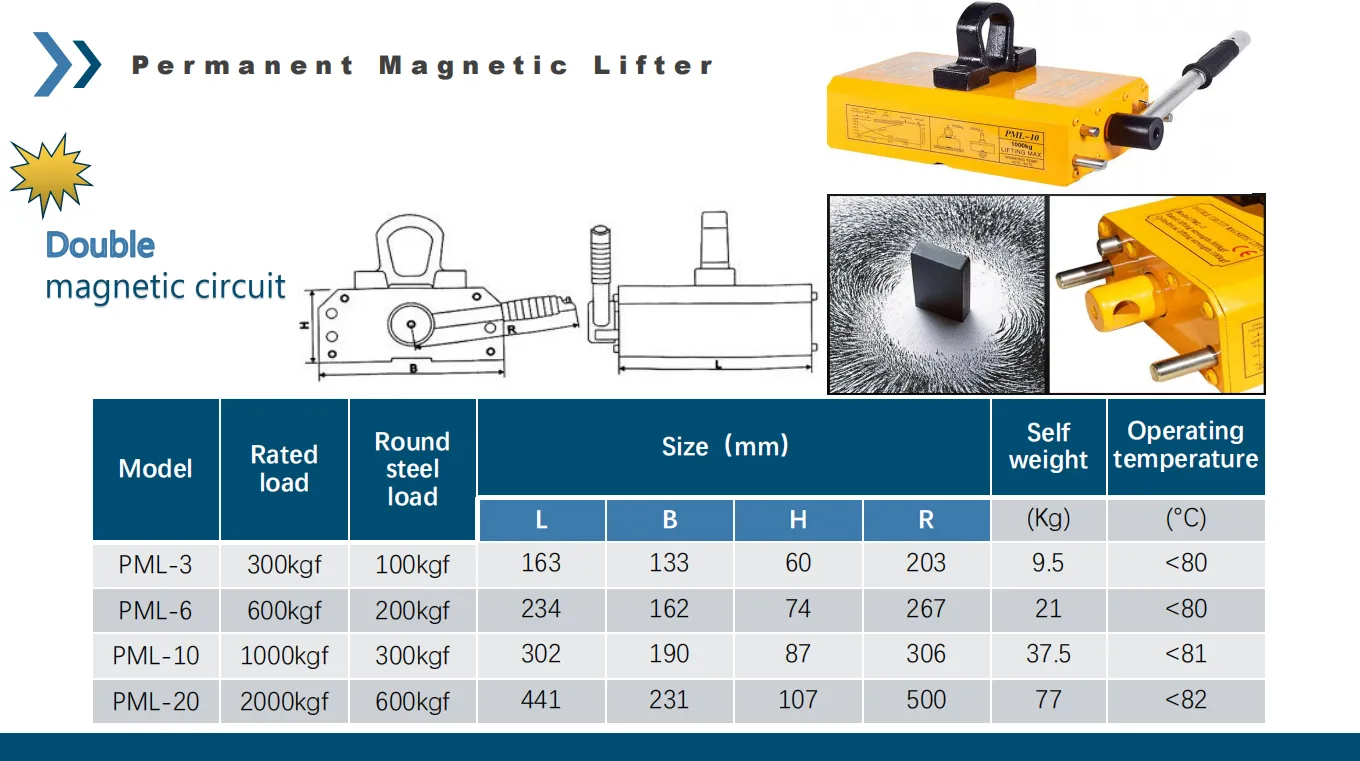

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025