Feb . 20, 2025 14:13

Back to list

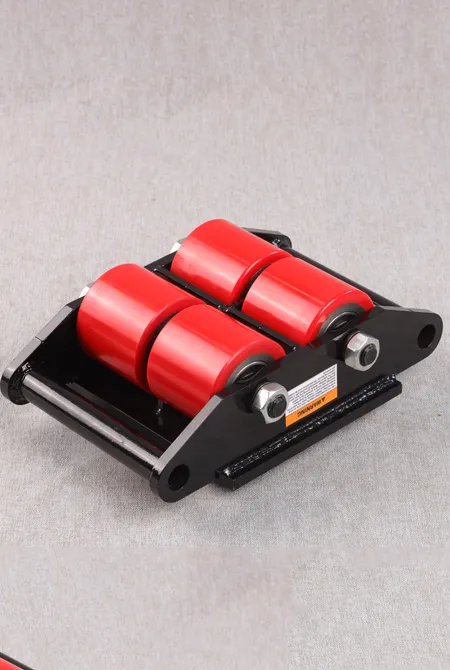

machinery skate dolly

In the world of heavy lifting and transportation within industrial and commercial settings, machinery skate dollies stand out as an essential tool, bridging the gap between safety, efficiency, and versatility. These robust platforms leverage cutting-edge engineering and design to facilitate the seamless movement of hefty machinery and equipment, transcending traditional limitations.

This trustworthiness can be further illustrated by examining case studies where machinery skate dollies have made significant impacts. For instance, in the aviation industry, moving aircraft engines, which demand caution and precision, is a task suited perfectly to machinery skate dollies. Their ability to distribute load evenly and glide smoothly over hangar floors showcases their indispensability. In construction and manufacturing sectors, the advantages further amplify. By reducing the need for complex rigging or cranes for short-distance indoor transfers, machinery skate dollies present a cost-effective and time-saving solution. Companies have reported substantial reductions in downtime and injury rates, attributing these gains to the strategic use of machinery skates. Looking forward, the evolution of machinery skate dollies continues with technological advancements like integration with the Internet of Things (IoT) for real-time tracking and automated movement solutions using AI. These developments aim to further enhance the precision and safety of load transportation, opening up new possibilities and applications in various industries. However, it is crucial for organizations considering the adoption of machinery skate dollies to conduct thorough assessments of their specific requirements. Partnering with reputable suppliers who offer not only quality products but also continue to provide post-purchase support and training is essential. By doing so, businesses not only optimize their operations but also build resilience and adaptability in their moving processes. In conclusion, machinery skate dollies represent a paradigm of innovation and practicality in the landscape of industrial operations. Their significance is magnified by the positive impacts they impart across multiple domains, underscoring their status as a cornerstone in modern heavy equipment management. With ongoing advancements and a steady focus on safety and efficiency, machinery skate dollies continue to march forward, carving a niche as indispensable allies in the world of heavy machinery movement.

This trustworthiness can be further illustrated by examining case studies where machinery skate dollies have made significant impacts. For instance, in the aviation industry, moving aircraft engines, which demand caution and precision, is a task suited perfectly to machinery skate dollies. Their ability to distribute load evenly and glide smoothly over hangar floors showcases their indispensability. In construction and manufacturing sectors, the advantages further amplify. By reducing the need for complex rigging or cranes for short-distance indoor transfers, machinery skate dollies present a cost-effective and time-saving solution. Companies have reported substantial reductions in downtime and injury rates, attributing these gains to the strategic use of machinery skates. Looking forward, the evolution of machinery skate dollies continues with technological advancements like integration with the Internet of Things (IoT) for real-time tracking and automated movement solutions using AI. These developments aim to further enhance the precision and safety of load transportation, opening up new possibilities and applications in various industries. However, it is crucial for organizations considering the adoption of machinery skate dollies to conduct thorough assessments of their specific requirements. Partnering with reputable suppliers who offer not only quality products but also continue to provide post-purchase support and training is essential. By doing so, businesses not only optimize their operations but also build resilience and adaptability in their moving processes. In conclusion, machinery skate dollies represent a paradigm of innovation and practicality in the landscape of industrial operations. Their significance is magnified by the positive impacts they impart across multiple domains, underscoring their status as a cornerstone in modern heavy equipment management. With ongoing advancements and a steady focus on safety and efficiency, machinery skate dollies continue to march forward, carving a niche as indispensable allies in the world of heavy machinery movement.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025