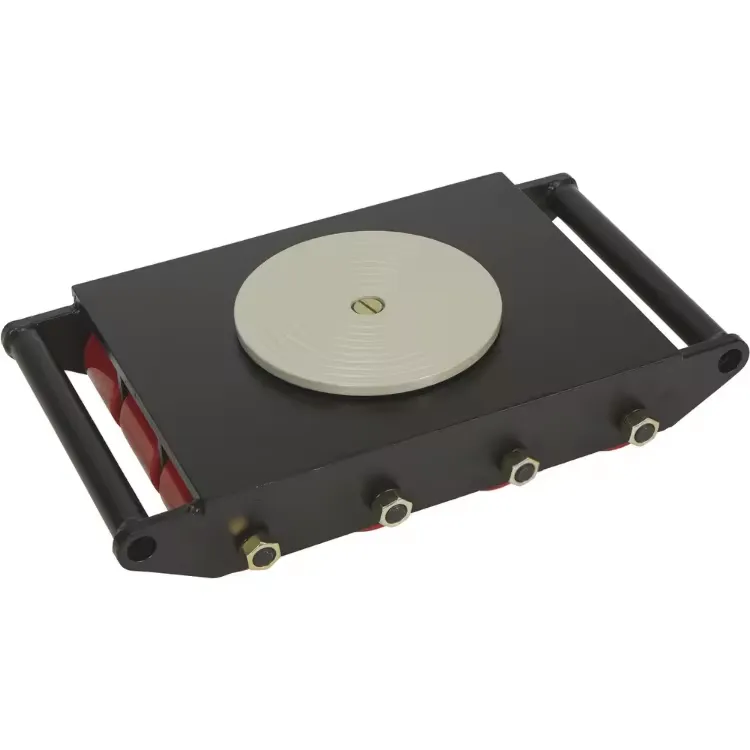

Dawei Straight Type Machinery Mover: Precise, Heavy-Duty (6-18T)

Driving Efficiency in Heavy-Duty Material Handling

In the demanding landscape of industrial material handling, the precise, safe, and efficient relocation of heavy machinery is paramount. Businesses across sectors from petrochemical to heavy manufacturing rely on robust, dependable equipment to maintain operational continuity and reduce downtime. This article focuses on the advanced capabilities and strategic advantages offered by the Dawei Machinery Mover Straight Type, a pivotal solution engineered for loads ranging from Rated Load 6000-18000 KGS.. We will delve into its technical prowess, application versatility, and the stringent manufacturing standards that guarantee its performance and longevity.

Understanding the critical role of specialized moving equipment, Dawei Hoisting commits to delivering innovations that not only meet but exceed industry expectations for safety, reliability, and efficiency. Our focus is on providing B2B clients with solutions that integrate seamlessly into their complex operational workflows, enhancing productivity and mitigating risks associated with heavy load transfer.

Current Industry Trends in Heavy Machinery Relocation

The heavy machinery moving sector is currently undergoing significant transformation, driven by several key trends. Automation and intelligent material handling systems are becoming increasingly prevalent, aiming to reduce human error and improve operational speed. There's also a strong emphasis on enhanced safety features, with stricter regulations and a corporate drive for zero-accident environments. Furthermore, the demand for equipment that can handle extremely heavy and irregularly shaped loads with precision is growing, particularly in advanced manufacturing, renewable energy, and critical infrastructure projects. Environmental sustainability is another rising concern, pushing for energy-efficient designs and durable materials that reduce waste and extend product lifecycles. Solutions like the Dawei Machinery Mover Straight Type are designed to address these evolving needs, offering a blend of robust construction, operational efficiency, and adherence to global safety standards for loads up to Rated Load 6000-18000 KGS..

The market is also seeing a shift towards more modular and adaptable solutions that can be scaled or customized for specific project requirements, avoiding the need for entirely new equipment purchases. This flexibility is crucial for industries that frequently reconfigure their production lines or facility layouts.

Technical Specifications and Parameters

The Dawei Machinery Mover Straight Type is engineered for precision and endurance, designed to handle substantial industrial loads with unparalleled stability. Its construction features high-grade alloy steel, treated for maximum strength and resistance to deformation under extreme pressure. Key components are manufactured using advanced forging and CNC machining processes, ensuring dimensional accuracy and structural integrity.

The design minimizes friction, ensuring smooth movement even with maximum load. The low profile design also reduces the required lift height, improving safety during initial placement. Each component, from the high-load bearings to the robust chassis, is selected for optimal performance and extended service life under continuous heavy-duty use.

The Dawei Manufacturing Process: Precision and Durability

The production of the Dawei Machinery Mover Straight Type adheres to a rigorous manufacturing process, ensuring each unit meets the highest standards of quality and performance. This multi-stage process integrates advanced engineering with meticulous quality control.

1. Material Selection & Sourcing

Utilizing high-grade alloy steels (e.g., Cr-Mo alloys) known for their superior tensile strength and wear resistance. Materials are sourced from certified suppliers and undergo stringent metallurgical analysis to confirm composition and properties.

2. Forging & Casting

Critical load-bearing components, such as the chassis and roller supports, are forged to enhance grain structure and eliminate internal defects, or precision cast for complex geometries, ensuring maximum strength and fatigue resistance.

3. CNC Machining

Computer Numerical Control (CNC) machining ensures precise dimensions and tight tolerances for all mating surfaces, roller axles, and bearing housings. This is critical for smooth operation and even load distribution across the Rated Load 6000-18000 KGS. capacity.

4. Heat Treatment & Surface Finishing

Components undergo controlled heat treatment processes (e.g., quenching and tempering) to achieve optimal hardness and toughness. A multi-layer corrosion-resistant coating (e.g., epoxy powder coating or galvanization) is applied for protection in harsh industrial environments, extending service life.

5. Assembly & Lubrication

Skilled technicians assemble the movers with high-quality, pre-lubricated sealed bearings. Precision alignment is ensured to minimize friction and wear during operation.

6. Quality Control & Testing

Each Dawei Machinery Mover Straight Type unit undergoes rigorous testing, including static load tests up to 125% of its rated capacity (e.g., Rated Load 6000-18000 KGS.), dynamic performance checks, and dimensional verification. Compliance with ISO 9001, CE, and ASME B30.1 standards is meticulously documented.

Target Industries and Advantages

The robust design and precision engineering of the Dawei Machinery Mover Straight Type make it indispensable across a spectrum of heavy industries:

- Petrochemical: For moving large pumps, compressors, and reactor components, where safety and anti-corrosion properties are critical.

- Metallurgy: Facilitating the relocation of heavy rolling mills, furnaces, and casting equipment in high-temperature and abrasive environments.

- Water Supply & Drainage: Transporting massive pumps, filtration units, and piping systems within municipal and industrial facilities.

- Heavy Manufacturing: Ideal for shifting presses, machine tools, and assembly line components during facility reconfigurations or installations.

- Energy Sector: Moving turbines, generators, and transformer units in power plants and renewable energy facilities.

Demonstrated Advantages:

- Energy Saving: Low rolling resistance due to precision-machined rollers and high-quality bearings minimizes the force required for movement, leading to reduced energy consumption during heavy load transfers.

- Corrosion Resistance: Specialized surface treatments and material selection ensure longevity and reliability even in corrosive or humid industrial environments.

- High Precision Movement: The straight-type design ensures linear movement with minimal deviation, crucial for accurately positioning sensitive or complex machinery.

- Enhanced Safety: Stable design and robust construction significantly reduce the risk of accidents during operations, protecting personnel and valuable assets.

Application Scenarios and Practical Use Cases

The versatility of the Dawei Machinery Mover Straight Type, with its capacity to handle a Rated Load 6000-18000 KGS., makes it an indispensable tool for a variety of critical industrial operations.

- Factory Relocation and Setup: Essential for efficiently moving entire production lines, large stamping presses, or injection molding machines during factory expansions or reconfigurations. The straight-line motion is ideal for long, unobstructed transfers.

- Heavy Equipment Maintenance: Facilitates the removal and reinstallation of massive components like industrial engines, large gearboxes, or generator sets for routine maintenance or repairs, minimizing downtime.

- Construction and Installation: Used in the installation of pre-fabricated sections of bridges, large structural beams, or heavy modular units on construction sites, offering a cost-effective and precise method of positioning.

- Warehouse and Logistics: For internal movement of oversized crates, heavy machinery parts, or bulk materials within large industrial warehouses where forklifts may not have the capacity or maneuverability.

- Shipbuilding and Offshore: Utilized for moving heavy sub-assemblies, engine blocks, or specialized equipment within shipyards or fabrication facilities for offshore platforms.

In each scenario, the straightforward operation and robust design ensure that heavy loads are moved safely and effectively, reducing manual labor and the potential for damage to both equipment and flooring.

Technical Advantages and Performance Differentiation

The distinct technical advantages of the Dawei Machinery Mover Straight Type set it apart in a competitive market, delivering superior value through enhanced performance, safety, and longevity.

- Optimized Load Distribution: Engineered with a wide, stable base and precisely aligned rollers, it ensures even distribution of the Rated Load 6000-18000 KGS., minimizing point loading and protecting valuable flooring surfaces. This also prevents structural stress on the machinery being moved.

- Low Coefficient of Friction: Utilizes high-performance, sealed bearings and ground rollers that significantly reduce frictional resistance. This translates into less effort required for movement, allowing for smaller towing equipment and reducing operational costs.

- Modular and Interlocking Design: While designed for straight movement, multiple units can be combined and interlocked to support exceptionally wide or long loads, providing adaptable capacity and stability for complex lifting and moving projects.

- Exceptional Durability and Service Life: Constructed from impact-resistant and fatigue-resistant materials, further enhanced by advanced heat treatments and anti-corrosion coatings. This robust build guarantees a prolonged service life, even under constant heavy use in challenging industrial environments, minimizing replacement cycles and total cost of ownership.

- Enhanced Safety Features: Includes anti-slip surfaces on load-bearing pads and robust attachment points for securing loads, ensuring maximum stability and preventing unintended movement during transport. The low height profile also enhances stability.

These advantages collectively contribute to a safer, more efficient, and cost-effective heavy machinery moving solution, distinguishing Dawei from conventional offerings.

Vendor Comparison: Why Choose Dawei Hoisting?

When selecting machinery movers, B2B clients evaluate factors like capacity, durability, safety, and after-sales support. While many manufacturers offer machinery movers, Dawei Hoisting's commitment to quality, innovation, and customer-centric solutions positions the Dawei Machinery Mover Straight Type as a leading choice for loads ranging from Rated Load 6000-18000 KGS..

Dawei Hoisting's commitment to rigorous testing, use of premium materials, and adherence to international safety standards translates into machinery movers that offer superior longevity, reliability, and peace of mind for heavy industrial applications. Our focus on engineering excellence and customer support differentiates us from the competition.

Customized Solutions and Engineering Expertise

Recognizing that every industrial challenge is unique, Dawei Hoisting offers extensive customization options for the Dawei Machinery Mover Straight Type. While our standard models efficiently handle a Rated Load 6000-18000 KGS., specific project requirements often demand tailored solutions.

Our team of experienced engineers works closely with clients to understand their specific operational environment, load characteristics (e.g., center of gravity, dimensions, floor conditions), and regulatory requirements. Customization options include:

- Increased Load Capacity: Engineering solutions for loads exceeding standard 18,000 KGS. capacity through reinforced chassis designs and specialized roller configurations.

- Specialized Roller Materials: Offering options like high-grade polyurethane rollers for sensitive flooring, anti-static rollers for explosive environments, or custom hardened steel rollers for extreme wear applications.

- Modified Dimensions: Adjustments to length, width, and height to accommodate specific machinery footprints or clearance limitations.

- Environmental Adaptations: Enhanced corrosion resistance for marine or chemical plant use, or specialized lubrication and seals for extreme temperature ranges.

- Integration with Control Systems: Design modifications to allow seamless integration with automated guidance systems or remote-controlled towing units for advanced material handling setups.

This bespoke approach ensures that clients receive a machinery mover that is perfectly optimized for their unique challenges, delivering maximum efficiency and safety without compromise. Our engineering capabilities allow us to go beyond off-the-shelf products, providing innovative solutions that solve complex material handling problems.

Application Case Studies: Proving Performance in Practice

The effectiveness of the Dawei Machinery Mover Straight Type is best illustrated through its successful deployment in various demanding industrial settings. These case studies highlight the mover's reliability and contribution to operational efficiency.

Case Study 1: Automotive Stamping Plant Upgrade

Client: Major Global Automotive Manufacturer

Challenge: Relocate a 15,000 KGS. sheet metal stamping press to a new foundation within a live production facility, requiring minimal disruption and precise alignment.

Solution: A set of four Dawei Machinery Mover Straight Type units, each rated for 5000 KGS., was deployed with a synchronized hydraulic jacking system. The movers' low-friction rollers and robust construction allowed for smooth, controlled movement over a distance of 50 meters.

Outcome: The press was repositioned and aligned within 0.5 mm tolerance in less than 8 hours, significantly reducing the planned downtime from 24 hours. The client reported excellent stability and ease of operation, directly attributing a 66% reduction in relocation time to the Dawei movers.

Case Study 2: Petrochemical Reactor Component Installation

Client: Leading Petrochemical Engineering Contractor

Challenge: Install a delicate 12,000 KGS. heat exchanger into a confined space within a refinery, requiring precise linear movement and corrosion resistance due to the environment.

Solution: Two Dawei Machinery Mover Straight Type units with polyurethane rollers (for floor protection) and enhanced corrosion-resistant coatings, each supporting a Rated Load 6000-18000 KGS. model, were used. Their straight-line precision was critical for navigating tight clearances.

Outcome: The heat exchanger was successfully guided into position without any damage to the component or the facility floor. The superior corrosion resistance of the movers ensured reliable performance throughout the project, which was conducted in a humid, salt-laden atmosphere.

Case Study 3: Hydropower Turbine Assembly

Client: International Hydropower Equipment Manufacturer

Challenge: Move large turbine sections, each weighing approximately 10,000 KGS., across an assembly hall with uneven concrete flooring for final integration.

Solution: A system comprising three Dawei Machinery Mover Straight Type units (10,000 KGS. model each) was utilized. Their robust chassis design and ability to handle slight floor imperfections ensured stable movement, while their precision bearings maintained alignment despite the rough terrain.

Outcome: The turbine sections were efficiently moved and positioned, significantly reducing the time and personnel required compared to previous methods involving overhead cranes. The minimal rolling resistance also contributed to an easier and safer operation.

Authoritativeness & Trustworthiness: Dawei Hoisting's Commitment

Certifications and Quality Assurance

Dawei Hoisting upholds the highest standards in manufacturing and quality control. Our products, including the Dawei Machinery Mover Straight Type, are manufactured under an ISO 9001 certified quality management system. This ensures consistent product quality from design to delivery. Furthermore, our movers comply with international safety and performance standards such as CE (Conformité Européenne) for European markets and often meet or exceed ASME B30.1 standards for jacking systems and material handling. Each unit undergoes rigorous testing, including proof load tests at 125% of its rated capacity (e.g., a 12,000 KGS. mover is tested to 15,000 KGS.), providing verifiable data on structural integrity and operational safety.

Customer Feedback & Service Excellence

"We recently used Dawei movers for a critical factory rearrangement, and the Rated Load 6000-18000 KGS. units performed flawlessly. The precision and stability were exceptional, allowing us to complete the project ahead of schedule and with complete confidence." – Operations Manager, Heavy Machinery Manufacturing Co.

Our client base includes numerous blue-chip companies across petrochemical, automotive, and energy sectors, reflecting our consistent delivery of high-performance and reliable material handling solutions for over two decades.

Frequently Asked Questions (FAQ)

Q: What is the maximum load capacity of the Dawei Machinery Mover Straight Type?

A: Our standard models offer a Rated Load 6000-18000 KGS.. We also offer customized solutions for higher capacities upon request.

Q: Can these movers be used on sensitive flooring?

A: Yes, we offer optional polyurethane rollers that provide excellent floor protection for sensitive surfaces while maintaining high load capacity.

Q: What is the expected service life of Dawei Machinery Movers?

A: With proper maintenance and use, the Dawei Machinery Mover Straight Type has an expected service life of 10-15 years, thanks to its robust construction and high-quality materials.

Q: Are spare parts readily available?

A: Yes, we maintain a comprehensive inventory of spare parts, ensuring prompt availability and minimal downtime for our clients.

Lead Time, Warranty, and Support

Lead Time: Standard models of the Dawei Machinery Mover Straight Type are typically available with a lead time of 2-4 weeks, depending on order volume and specific configurations. Custom orders may require longer lead times, which will be communicated clearly during the quotation process.

Warranty: Dawei Hoisting provides a comprehensive 12-month warranty on all machinery movers, covering manufacturing defects and material failures under normal operating conditions. Extended warranty options are available.

Customer Support: Our dedicated after-sales support team is available to assist with technical queries, maintenance advice, and spare parts procurement. We offer global support through our network of distributors and service partners, ensuring rapid response and minimal operational disruption.

Conclusion

The Dawei Machinery Mover Straight Type, with its robust construction and precision engineering for loads up to Rated Load 6000-18000 KGS., stands as a testament to Dawei Hoisting's commitment to excellence in heavy industrial material handling. By integrating advanced manufacturing processes, adhering to stringent quality standards, and offering comprehensive support, we empower businesses to execute complex machinery relocations with unmatched safety, efficiency, and reliability. Investing in Dawei movers is an investment in uninterrupted operations and long-term performance.

References

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems – Requirements.

- American Society of Mechanical Engineers. (2020). ASME B30.1-2020 - Jacks, Industrial Rollers, Air Casters, and Telescoping Jacks.

- European Committee for Standardization. (Various). CE Marking Directives for Machinery.

- Journal of Manufacturing Processes. (2019). Advancements in Heavy-Duty Material Handling Equipment Design and Safety. Volume 45, pp. 321-335.

- Industrial Engineering & Management Journal. (2021). Optimizing Factory Layouts with Precision Moving Equipment. Vol. 18, No. 3, pp. 112-125.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025