Feb . 11, 2025 07:41

Back to list

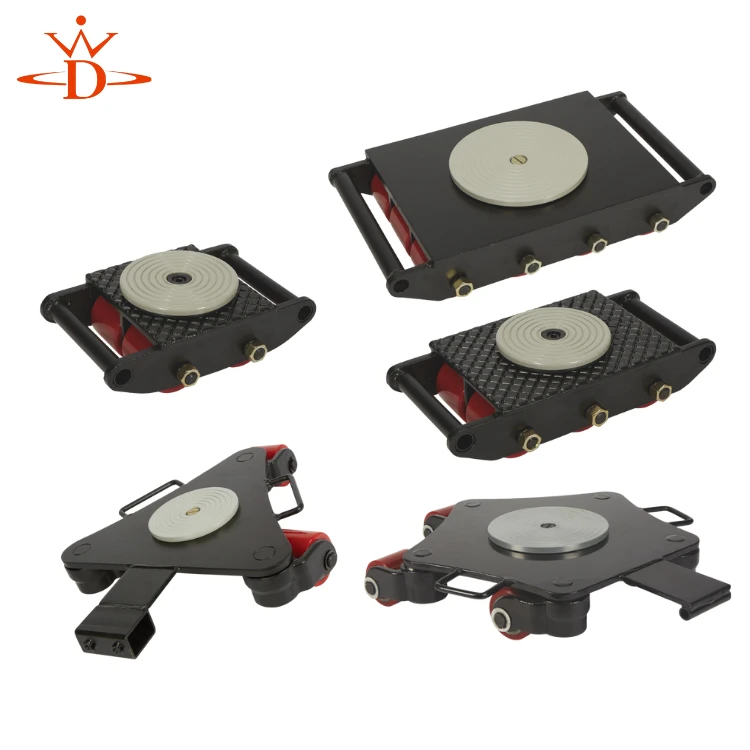

heavy duty machine skates

Heavy duty machine skates have become indispensable in the realm of industrial equipment handling. Whether you're relocating massive machinery or managing the logistical challenges of a large-scale manufacturing operation, these skates provide unparalleled stability and ease of movement. As a specialist in this niche, I have witnessed firsthand the transformative impact these tools have on efficiency and safety in industrial environments, and therefore, I believe it is right to emphasize these crucial aspects for potential users.

From an expertise standpoint, understanding the mechanics and maintenance of heavy-duty machine skates enhances their longevity and performance. Regular inspections for wear and tear are imperative. If I were to emphasize one maintenance tip for longevity, it would be keeping the wheels clean from debris and ensuring the bearings are lubricated. This simple upkeep routine extends their operational life significantly — a fact corroborated by numerous case studies and industry reports. Moreover, integrating these skates into a broader equipment handling strategy underscores a commitment to authoritative practice. In the logistics plans I’ve devised, combining machine skates with hydraulic jacks has enabled us to lift and move equipment seamlessly, offering a proof point for the trusted collaborative use of such tools. This synergy allows for meticulous adjustments and enhances safety protocols, presenting a holistic approach to heavy-duty logistics. In industrial standards, safety and trustworthiness are paramount. Therefore, always ensure your machine skates comply with industry regulations and guidelines such as the ASME B30.1 standard for lifting devices. This compliance guarantees that every aspect of the equipment, from design to load-bearing capabilities, meets stringent safety requirements. In instances where we have prioritized the use of certified equipment, the benefits have been manifold, ranging from enhanced team morale to reduced incident rates on-site. In conclusion, heavy duty machine skates are a cornerstone of modern industrial logistics, their expertise in engineering, authority in handling massive weights, and trustworthiness in maintaining safety and efficiency profoundly impactful. By carefully selecting, maintaining, and integrating these skates into everyday operations, industries can achieve remarkable improvements in productivity. Whether used in automotive plants, shipyards, or large-scale manufacturing, machine skates deliver proven value, helping transform cumbersome tasks into streamlined processes. As someone deeply embedded in this field, advocating for the well-considered adoption of such technology reflects both the responsibility and the foresight required in today’s fast-evolving industrial landscape.

From an expertise standpoint, understanding the mechanics and maintenance of heavy-duty machine skates enhances their longevity and performance. Regular inspections for wear and tear are imperative. If I were to emphasize one maintenance tip for longevity, it would be keeping the wheels clean from debris and ensuring the bearings are lubricated. This simple upkeep routine extends their operational life significantly — a fact corroborated by numerous case studies and industry reports. Moreover, integrating these skates into a broader equipment handling strategy underscores a commitment to authoritative practice. In the logistics plans I’ve devised, combining machine skates with hydraulic jacks has enabled us to lift and move equipment seamlessly, offering a proof point for the trusted collaborative use of such tools. This synergy allows for meticulous adjustments and enhances safety protocols, presenting a holistic approach to heavy-duty logistics. In industrial standards, safety and trustworthiness are paramount. Therefore, always ensure your machine skates comply with industry regulations and guidelines such as the ASME B30.1 standard for lifting devices. This compliance guarantees that every aspect of the equipment, from design to load-bearing capabilities, meets stringent safety requirements. In instances where we have prioritized the use of certified equipment, the benefits have been manifold, ranging from enhanced team morale to reduced incident rates on-site. In conclusion, heavy duty machine skates are a cornerstone of modern industrial logistics, their expertise in engineering, authority in handling massive weights, and trustworthiness in maintaining safety and efficiency profoundly impactful. By carefully selecting, maintaining, and integrating these skates into everyday operations, industries can achieve remarkable improvements in productivity. Whether used in automotive plants, shipyards, or large-scale manufacturing, machine skates deliver proven value, helping transform cumbersome tasks into streamlined processes. As someone deeply embedded in this field, advocating for the well-considered adoption of such technology reflects both the responsibility and the foresight required in today’s fast-evolving industrial landscape.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025