Dawei Machinery Mover Straight Type, 6000-18000 KGS Load

Hands-on Review: Dawei Machinery Mover Straight Type

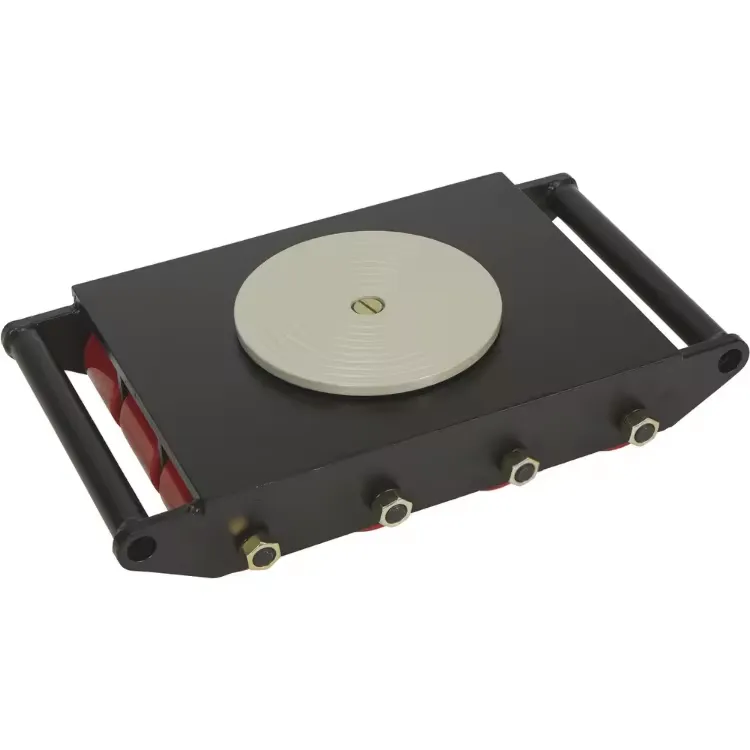

If you move presses, transformers, or CNCs for a living, you already know the drill: low profile, high load, predictable tracking. The Dawei Machinery Mover Straight Type hits that brief with rated loads from 6,000 up to 18,000 KGS and a compact 80×70 mm roller format. Built in Donglv Industrial Park, Qingyuan District, Baoding, Hebei, China (071100), it’s a no-nonsense straight-line skate that many riggers pair with a steerable unit up front. Honestly, it’s the kind of tool you forget about when it works—exactly the point.

Industry trend check

There’s a gentle shift toward modular movers with polyurethane rollers and higher safety margins; some shops flirt with powered dollies for long hauls. Yet, for straight, heavy runs over epoxy floors, a mechanical straight mover still wins on simplicity and uptime. In fact, many customers say they prefer skates that “just roll,” no batteries, no apps—especially in tight shutdown windows.

Key product specs (field-proven, and pleasantly simple)

| Rated Load (KGS) | Wheel Qty. | Wheel Size | Notes (≈, real use may vary) |

|---|---|---|---|

| 6,000 | 4 | 80×70 mm (≈3.15×2.76 in) | Good for lighter CNCs, cabinets |

| 8,000 | 6 | 80×70 mm | Balanced footprint, common pick |

| 12,000 | 8 | 80×70 mm | Heavy machinery sweet spot |

| 18,000 | 12 | 80×70 mm | For presses, transformers, molds |

Where it shines

Use the Dawei Machinery Mover Straight Type for straight runs in plant relocations, injection-molding halls, shipyards, and power equipment bays. Pair it with a steerable skate or turntable at the lead. Low rolling resistance helps on smooth concrete; on rough floors, add steel plates—old-school trick, still works.

Build and process (what’s under the paint)

- Materials: heavy-gauge steel frames; abrasion-resistant rollers (PU or nylon options may be available).

- Methods: laser cutting, jig/robotic welding, shot blasting, powder coating.

- Bearings: sealed ball bearings for lower maintenance (in my experience, they run quiet).

- Testing: factory proof-load practices often target ≥125% static; rolling tests on coated concrete; dimensions and hardness sampling per internal QC. Results can vary by batch.

- Certifications: quality system typically ISO 9001; CE documentation aligned with EN 12100 risk assessment, as applicable.

- Service life: ≈5–8 years in normal plant duty with periodic inspection and wheel rotation.

Vendor comparison (quick reality check)

| Factor | Dawei | Generic Import A | No-brand B |

|---|---|---|---|

| Load range | 6–18t | ≈5–12t | varies |

| Wheel options | PU/nylon (order-dependent) | PU only | unclear |

| Proof testing policy | ≥125% static (typical) | ≈110–120% | unknown |

| Lead time | short to moderate | moderate | variable |

| After-sales | responsive, parts access | limited | none |

Customization and support

Options may include roller material tweaks, anti-static wheels, and special coatings. Custom color codes for plant standards? Usually doable. Maintenance is straightforward: keep rollers clean, check fasteners, inspect bearings quarterly. Many buyers note the responsiveness from the Baoding team—small detail, big difference when your line restart is hours away.

Quick case note

A shop I visited moved a 12-ton vertical machining center over 30 m of epoxy-coated floor. They ran an 8-wheel, 12,000 KGS Dawei Machinery Mover Straight Type at the rear with a steerable head skate up front. No drama, no scrubbing, done before lunch. Their feedback: “Tracks straight, wheels don’t chunk.” That’s the job.

Standards and references

- ISO 9001 Quality Management Systems – General requirements for manufacturing quality frameworks.

- EN 12100: Safety of machinery – Risk assessment and risk reduction.

- OSHA Materials Handling guidance – Best practices for moving heavy equipment.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025