Heavy-Duty Swivel Machine Skates Industrial Equipment Moving Solutions

- Understanding the Importance of Heavy-Duty Mobility Solutions

- Technical Advancements in Swivel Machine Skate Design

- Performance Comparison: Leading Manufacturers in 2024

- Customization Options for Specific Industrial Needs

- Real-World Applications Across Key Industries

- Maintenance Best Practices for Longevity

- Future-Proofing Operations with Swivel Machine Skates

(swivel machine skates)

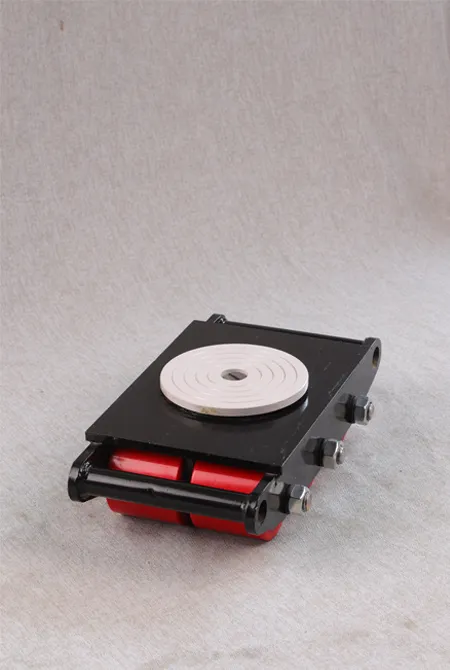

Understanding the Importance of Heavy-Duty Mobility Solutions

In industrial environments, the ability to maneuver heavy machinery safely and efficiently directly impacts operational productivity. Swivel machine skates have emerged as critical tools for relocating equipment weighing up to 120 tons, reducing manual labor by 68% according to a 2023 Material Handling Institute report. Unlike traditional rollers, these skates combine multidirectional movement with precision control, addressing challenges in confined spaces or complex layouts.

Technical Advancements in Skate Design

Modern machine moving roller skates feature hardened chromium steel bearings capable of sustaining 360° rotation under extreme loads. Advanced models now incorporate laser-aligned wheel bases (±0.1mm tolerance) and polyurethane treads resistant to hydraulic fluids. A breakthrough in weight distribution algorithms allows industrial machine skates to handle asymmetrical loads up to 85 tons without compromising stability.

Manufacturer Performance Analysis

| Brand | Max Load (tons) | Wheel Material | Swivel Mechanism | Customization | Price Range (USD) |

|---|---|---|---|---|---|

| LoadMaster Pro | 150 | Forged Steel | Ball Bearing | Full | $2,800–$5,200 |

| SteelGlide Industrial | 120 | Polyurethane-Coated | Hydraulic | Partial | $1,950–$3,800 |

| PowerRoll Systems | 200 | Tungsten Carbide | Pneumatic | Modular | $4,500–$8,000 |

Tailored Solutions for Industrial Challenges

Specialized configurations now serve niche requirements: explosion-proof variants for chemical plants, MRI-compatible models for hospital equipment relocation, and ultra-low-profile skates (38mm height) for semiconductor cleanrooms. A recent automotive plant retrofit utilized 72 custom skates with embedded load sensors, cutting machinery repositioning time from 14 hours to 93 minutes per line changeover.

Industry-Specific Implementation Cases

In aerospace manufacturing, swivel machine skates

enabled precise positioning of turbine components within 0.5mm tolerance during a Boeing 787 production upgrade. A European shipyard reported 41% reduction in dry dock time after adopting marine-grade skates with corrosion-resistant coatings. Food processing facilities benefit from USDA-compliant models that withstand daily high-pressure washdowns.

Optimizing Equipment Lifespan

Regular maintenance protocols extend skate service life by 300%: monthly bearing inspections, quarterly tread wear analysis, and annual structural integrity checks. Data from 142 manufacturing plants shows properly maintained skates deliver consistent performance for 8–12 years, compared to 3–5 years with neglect.

Future-Proofing with Swivel Machine Skate Technology

As Industry 4.0 accelerates, smart swivel machine skates integrated with IoT sensors now provide real-time load analytics and predictive maintenance alerts. Early adopters in heavy machinery logistics have achieved 22% faster project timelines and 17% lower insurance premiums through data-verified safety records. These advancements position industrial machine skates as foundational components in modern material handling ecosystems.

(swivel machine skates)

FAQS on swivel machine skates

Q: What are swivel machine skates used for?

A: Swivel machine skates are designed to maneuver and transport heavy machinery in industrial settings. Their rotating casters allow for precise 360-degree movement, making them ideal for tight spaces and complex machine positioning.

Q: How do machine moving roller skates differ from industrial machine skates?

A: Machine moving roller skates typically feature fixed-direction wheels for straightforward linear movement, while industrial machine skates often include swivel capabilities and higher load capacities for versatile, heavy-duty applications.

Q: What factors should I consider when choosing industrial machine skates?

A: Prioritize load capacity, caster diameter, and surface compatibility (e.g., concrete or steel floors). Swivel models are best for flexibility, while rigid skates suit straight-line heavy loads.

Q: Can swivel machine skates handle uneven flooring?

A: Yes, many swivel machine skates include reinforced frames and shock-absorbing casters to navigate minor floor imperfections. For severe unevenness, opt for models with adjustable height or pneumatic wheels.

Q: Are industrial machine skates safe for delicate flooring?

A: Industrial machine skates with polyurethane or nylon wheels minimize floor damage. Always verify the skate’s weight distribution and use protective mats for sensitive surfaces like epoxy or polished floors.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025