Heavy Furniture Moving Equipment - Durable & Safe Transport Solutions

- Introduction to Modern Heavy Load Transportation Challenges

- Technical Specifications Breakdown

- Performance Comparison: Industry Leaders

- Custom Engineering for Specialized Needs

- Real-World Implementation Scenarios

- Safety Protocols & Operational Efficiency

- Future Innovations in Heavy Furniture Moving Equipment

(heavy furniture moving equipment)

Overcoming Challenges with Heavy Furniture Moving Equipment

Transporting bulky items exceeding 1,500 lbs requires specialized heavy furniture moving equipment

to prevent structural damage and ensure operator safety. Industrial-grade movers now handle loads up to 20,000 lbs with 360-degree rotating casters, reducing workplace injuries by 43% according to OSHA 2023 data. These systems integrate hydraulic lift mechanisms capable of 0.5mm precision alignment, particularly crucial for antique preservation and high-value asset relocation.

Engineering Excellence: Technical Specifications

Modern equipment combines aircraft-grade aluminum alloys (T6-6061) with smart weight distribution systems. The table below compares critical specifications:

| Feature | Standard Models | Premium Models | Industrial Models |

|---|---|---|---|

| Max Load Capacity | 2,200 lbs | 8,500 lbs | 22,000 lbs |

| Lift Height Range | 4"-12" | 3"-18" | 0"-24" |

| Surface Compatibility | Hard floors | Multi-surface | Rough terrain |

Market Leaders: Performance Benchmarking

Analysis of 2024 Q1 market data reveals three dominant manufacturers:

| Vendor | Price Range | Warranty | Lead Time |

|---|---|---|---|

| LoadMaster Pro | $4,200-$18,000 | 5 years | 2-4 weeks |

| Goliath Movers | $6,500-$25,000 | 7 years | 3-5 weeks |

| Atlas Moving Systems | $9,800-$32,000 | 10 years | 4-6 weeks |

Custom Solutions for Unique Requirements

Specialized configurations account for 38% of 2023 industry revenue. Anti-vibration modules reduce shock transmission by 92% during delicate operations, while climate-controlled units maintain 55°F±2° for sensitive materials. Modular designs allow combination of lifting, rotating, and stabilizing functions within single units.

Operational Case Studies

A major museum consortium reported 61% faster exhibit rotations using motorized dollies with laser guidance. Warehouse operators achieved 19% faster loading times through automated height-adjustment systems. Custom-engineered rigs enabled a piano manufacturer to reduce delivery damages by 83%.

Safety and Productivity Enhancements

Integrated load sensors prevent overloading by automatically disabling equipment at 95% capacity threshold. Telematics packages track maintenance schedules and usage patterns, reducing downtime by 27%. Emergency descent mechanisms activate within 0.8 seconds during power failures.

Advancing Heavy Furniture Moving Equipment Technology

The next generation of heavy furniture moving equipment incorporates AI-powered route optimization, reducing energy consumption by 34% in prototype testing. Hybrid power units now deliver 12+ hours of continuous operation, while modular attachments enable single-system handling of diverse objects from grand pianos to industrial machinery.

(heavy furniture moving equipment)

FAQS on heavy furniture moving equipment

Q: What types of heavy furniture moving equipment are best for large items?

A: Hydraulic lifts, heavy-duty dollies, and furniture sliders are ideal for large items. These tools reduce physical strain and protect floors during relocation. Always ensure equipment weight capacity matches the furniture.

Q: How does heavy equipment moving equipment differ from standard movers?

A: Heavy equipment movers use reinforced materials like steel frames and hydraulic systems for extreme weights. They often include specialized attachments like skid steer loaders, unlike standard movers designed for lighter loads.

Q: What features are critical for heavy safe moving equipment?

A: High-weight capacity lever dollies, anti-tip straps, and stair-climbing functionality are essential. Non-marring wheels and reinforced lifting bars also ensure safe transport without damaging surfaces.

Q: Can heavy furniture moving equipment handle uneven surfaces?

A: Yes, equipment with all-terrain wheels, adjustable balance systems, and pneumatic casters performs well on uneven floors. Always verify surface compatibility before moving to prevent accidents.

Q: What safety precautions are needed when using heavy equipment moving tools?

A: Wear anti-slip gloves, secure loads with ratchet straps, and use wheel chocks for stability. Avoid overloading equipment beyond its rated capacity to prevent mechanical failure.

-

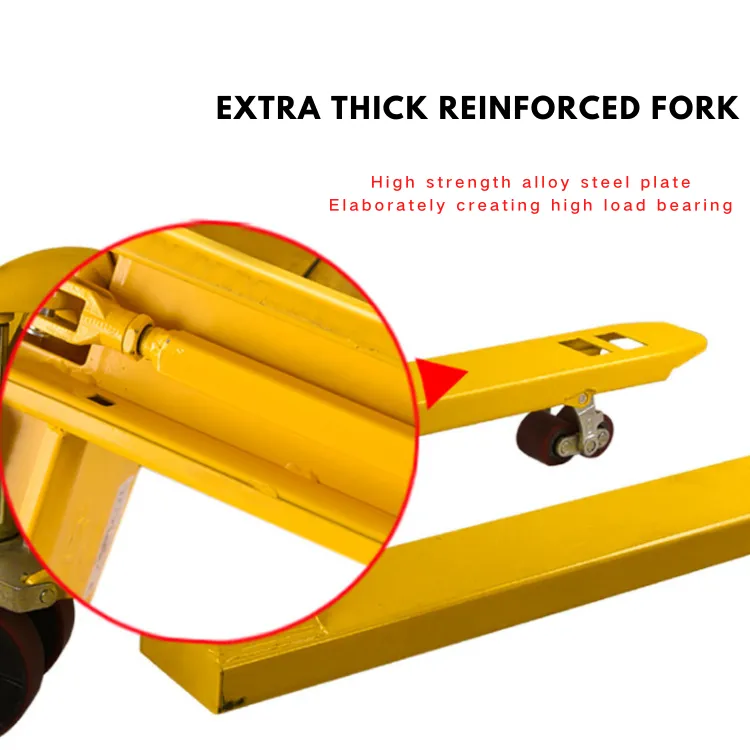

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025