Feb . 15, 2025 00:10

Back to list

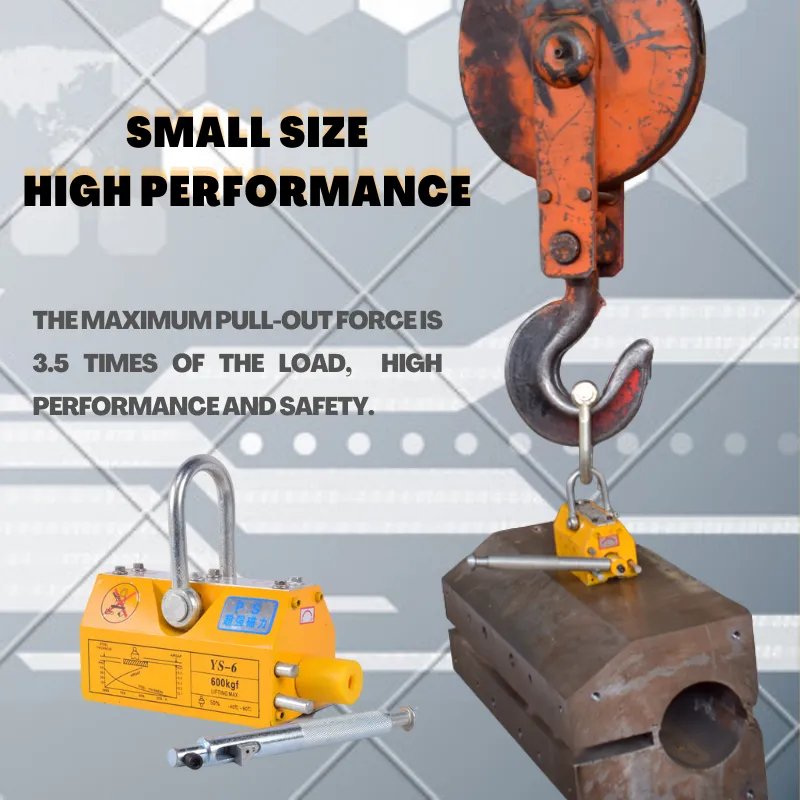

sheet metal magnetic lifter

Sheet metal magnetic lifters are revolutionizing the way industries handle heavy metal sheets, and it's essential to understand their benefits, applications, and the technology behind them to make an informed purchasing decision.

Trustworthiness is perhaps one of the most critical elements when considering a tool that's integral to safety in an industrial setting. Sheet metal magnetic lifters have earned this trust by proving their durability and effectiveness repeatedly. When maintained properly, they can last for years without diminishing in performance, offering companies an excellent return on investment. Companies should ensure they purchase from reputable brands with certifications and positive industry reviews to ensure they receive the highest quality products. Cutting-edge industries that utilize sheet metal magnetic lifters include automotive, aerospace, and heavy machinery manufacturing. These sectors demand precision and safety, and magnetic lifters meet these needs comprehensively. The aerospace industry, in particular, leverages these tools for their ability to handle delicate metal sheets without causing damage, thus ensuring that material integrity is maintained. Moreover, the environmental impact is an emerging consideration. Magnetic lifters provide an energy-efficient solution to sheet metal handling. Compared to continuous power-induced systems, permanent magnetic lifters only consume energy when altering their magnetic state, showcasing them as eco-friendly options that do not compromise on power or safety. In conclusion, the sheet metal magnetic lifter stands out as a modern marvel in industrial material handling. Its contribution to safety, efficiency, and the overall productivity of workplaces highlights its essential role in contemporary industry. Businesses looking to enhance their fabrication or manufacturing processes should consider integrating sheet metal magnetic lifters into their operations to remain at the forefront of innovation and safety. Given the evidence and expert endorsements, the benefits of investing in these magnetic lifters are indisputable, ensuring industries not only keep pace with but also lead in their respective fields.

Trustworthiness is perhaps one of the most critical elements when considering a tool that's integral to safety in an industrial setting. Sheet metal magnetic lifters have earned this trust by proving their durability and effectiveness repeatedly. When maintained properly, they can last for years without diminishing in performance, offering companies an excellent return on investment. Companies should ensure they purchase from reputable brands with certifications and positive industry reviews to ensure they receive the highest quality products. Cutting-edge industries that utilize sheet metal magnetic lifters include automotive, aerospace, and heavy machinery manufacturing. These sectors demand precision and safety, and magnetic lifters meet these needs comprehensively. The aerospace industry, in particular, leverages these tools for their ability to handle delicate metal sheets without causing damage, thus ensuring that material integrity is maintained. Moreover, the environmental impact is an emerging consideration. Magnetic lifters provide an energy-efficient solution to sheet metal handling. Compared to continuous power-induced systems, permanent magnetic lifters only consume energy when altering their magnetic state, showcasing them as eco-friendly options that do not compromise on power or safety. In conclusion, the sheet metal magnetic lifter stands out as a modern marvel in industrial material handling. Its contribution to safety, efficiency, and the overall productivity of workplaces highlights its essential role in contemporary industry. Businesses looking to enhance their fabrication or manufacturing processes should consider integrating sheet metal magnetic lifters into their operations to remain at the forefront of innovation and safety. Given the evidence and expert endorsements, the benefits of investing in these magnetic lifters are indisputable, ensuring industries not only keep pace with but also lead in their respective fields.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025