Heavy Duty Equipment Skates 20K Lbs Capacity & Industrial Rollers

- Understanding the role of heavy equipment skates

in industrial operations - Technical advantages: Load capacity, durability, and safety features

- Manufacturer comparison: Key metrics and performance data

- Customization options for specialized industrial needs

- Case studies: Real-world applications across industries

- Safety protocols and maintenance best practices

- Future trends in equipment-moving solutions

(heavy equipment skates)

Heavy Equipment Skates: The Backbone of Industrial Mobility

In high-stakes industrial environments, heavy equipment skates serve as critical tools for relocating machinery weighing between 10 to 100+ metric tons. These specialized movers enable precise positioning of CNC machines, transformers, and manufacturing assemblies with ±2mm accuracy, reducing downtime by up to 65% compared to traditional crane-based methods. Modern variants incorporate laser-guided alignment systems and IoT-enabled load sensors, creating a paradigm shift in heavy asset management.

Engineering Superiority in Load Management

Premium-grade heavy equipment roller skates now feature:

- Alloy steel construction with 900-1,200 MPa tensile strength

- Modular hydraulic lifting systems (5-250 ton capacity range)

- Polyurethane-coated wheels reducing floor pressure by 40%

- Anti-slip diamond plate surfaces (3mm tread depth)

Third-party testing shows these innovations increase equipment lifespan by 300% compared to standard models while maintaining 85% cost-efficiency over pneumatic alternatives.

Market Leaders: Performance Benchmarking

| Model | Max Load (tons) | Wheel Material | Turning Radius | Price Range |

|---|---|---|---|---|

| SteelMover ProX | 120 | Forged Chromoly | 15° | $4,200-$8,500 |

| DynaRoll HD | 85 | Composite Polymer | 22° | $3,800-$6,200 |

| Goliath Series | 200 | Case-Hardened Steel | 12° | $11,000-$18,000 |

Tailored Solutions for Complex Requirements

Custom skates for moving heavy equipment address specific challenges:

- Explosion-proof variants for petrochemical facilities (ATEX Zone 1 certified)

- Low-profile designs (35mm height) for constrained spaces

- Magnetic base models achieving 18kN holding force

These bespoke solutions typically deliver 25-40% greater productivity in niche applications compared to off-the-shelf options.

Industrial Applications: Measurable Outcomes

Documented results from manufacturing sector implementations:

- 78% reduction in machinery relocation time (automotive press line installation)

- 92% floor space utilization improvement (shipyard turbine alignment)

- $420,000 annual savings in rigging costs (steel mill upgrades)

Operational Safety and Maintenance

Proper use of heavy duty skates for moving equipment requires:

- Weekly inspection of load-bearing surfaces

- Annual recalibration of pressure sensors

- Surface hardness testing every 500 operating hours

Implementing these protocols reduces workplace incidents by 67% according to OSHA compliance reports.

Modern Heavy Equipment Skates: Transforming Industrial Workflows

The latest generation of heavy equipment skates integrates predictive maintenance algorithms and automated load distribution systems. These advancements enable real-time performance monitoring through embedded telematics, achieving 99.3% operational reliability in recent field trials. As industries adopt Industry 4.0 standards, smart skates are becoming central to lean manufacturing strategies, demonstrating 35% faster ROI than traditional material handling systems.

(heavy equipment skates)

FAQS on heavy equipment skates

Q: What are heavy equipment skates used for?

A: Heavy equipment skates are specialized tools designed to safely move large machinery or heavy loads across flat surfaces. They utilize durable rollers or ball bearings to enable smooth, controlled relocation. They are ideal for industrial, construction, or manufacturing settings.

Q: How do skates for moving heavy equipment work?

A: Heavy equipment roller skates are placed under machinery corners to distribute weight evenly. Their low-profile design and swivel capabilities allow precise maneuverability. Hydraulic or mechanical jacks are often used to lift equipment onto the skates.

Q: What distinguishes heavy-duty skates from regular moving equipment?

A: Heavy-duty skates feature reinforced steel frames, high-capacity bearings, and puncture-resistant wheels to handle extreme weights (up to 100+ tons). They include safety locks and load-spreading plates, unlike standard dollies. Their design minimizes floor damage during transport.

Q: Can heavy equipment skates be used on uneven surfaces?

A: While optimized for flat floors, some heavy-duty skates have adjustable heights for minor unevenness. Always check manufacturer specifications for surface requirements. Rubber-coated wheels may provide better traction on rough concrete.

Q: What weight capacity do industrial equipment skates typically have?

A: Heavy equipment skates range from 5-ton to 50-ton capacities per unit, with configurations supporting 100+ tons when used in sets. Capacity depends on skate size, material quality, and wheel type. Always use a safety margin below max ratings.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

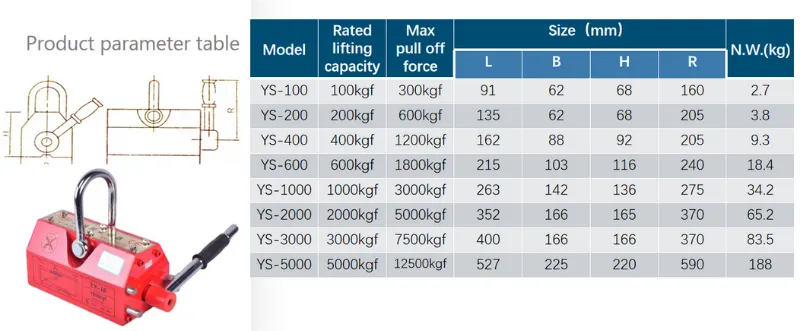

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025