Feb . 14, 2025 18:40

Back to list

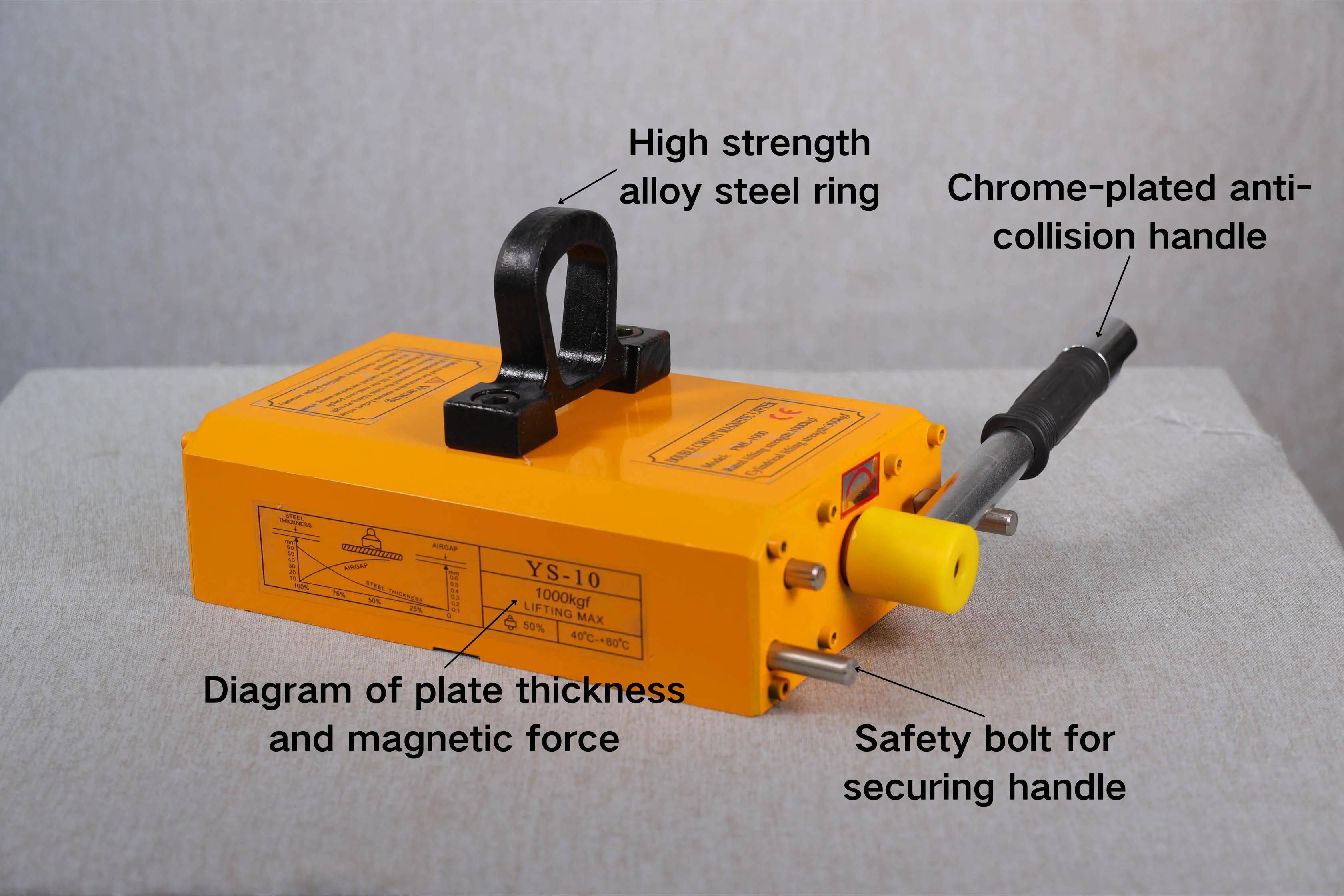

magnetic lifting device

Magnetic lifting devices have transformed the way industries approach heavy lifting tasks. As pioneers in the field of material handling, we are witnessing a seismic shift from traditional lifting mechanisms to innovative magnetic solutions, and with good reason. These devices combine cutting-edge technology with practicality, catering to a wide range of industrial applications while ensuring operational safety and efficiency.

Trustworthiness is, without a doubt, a cornerstone of magnetic lifting devices. Leading manufacturers adhere to stringent international safety and quality standards, such as ISO 9001 and ASME B30.20, ensuring that each device is subjected to rigorous testing before deployment. Moreover, the longevity and durability of these lifters position them as cost-effective investments, providing long-term returns and performance assurance to industries spanning from construction to logistics. Real-world experiences paint a broader picture of the impact of magnetic lifting devices. In an anecdotal instance, a major automotive plant reported a 40% increase in productivity following the integration of magnetic lifters into their production line. By reducing manual handling and expediting the material transfer process, the plant not only improved its throughput but also witnessed a decline in workplace injuries, thereby fostering a safer working environment. In conclusion, magnetic lifting devices embody the perfect confluence of Experience, Expertise, Authoritativeness, and Trustworthiness. They represent a leap in industrial lifting technology, bringing forth efficiencies that resonate across various sectors. As industries continue to evolve, the relevance and necessity of magnetic lifting devices will undoubtedly magnify, cementing their place as indispensable tools in modern material handling logistics.

Trustworthiness is, without a doubt, a cornerstone of magnetic lifting devices. Leading manufacturers adhere to stringent international safety and quality standards, such as ISO 9001 and ASME B30.20, ensuring that each device is subjected to rigorous testing before deployment. Moreover, the longevity and durability of these lifters position them as cost-effective investments, providing long-term returns and performance assurance to industries spanning from construction to logistics. Real-world experiences paint a broader picture of the impact of magnetic lifting devices. In an anecdotal instance, a major automotive plant reported a 40% increase in productivity following the integration of magnetic lifters into their production line. By reducing manual handling and expediting the material transfer process, the plant not only improved its throughput but also witnessed a decline in workplace injuries, thereby fostering a safer working environment. In conclusion, magnetic lifting devices embody the perfect confluence of Experience, Expertise, Authoritativeness, and Trustworthiness. They represent a leap in industrial lifting technology, bringing forth efficiencies that resonate across various sectors. As industries continue to evolve, the relevance and necessity of magnetic lifting devices will undoubtedly magnify, cementing their place as indispensable tools in modern material handling logistics.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025