Industrial Machine Skates Heavy-Duty Equipment Moving Solutions

- Introduction to industrial machine skates

and their role in heavy equipment handling - Technical advantages of modern industrial skates

- Comparative analysis of leading manufacturers

- Customization options for specialized requirements

- Real-world applications across industries

- Maintenance and safety best practices

- Strategic benefits of optimized equipment movement

(industrial machine skates)

Powering Heavy Industry with Industrial Machine Skates

Industrial machine skates have become indispensable in sectors requiring precise movement of heavy loads, with the global material handling equipment market projected to reach $317.56 billion by 2032 (CAGR 6.7%). These systems enable relocation of machinery weighing up to 1,200 tons while maintaining 0.5° tilt tolerance, revolutionizing plant floor logistics.

Engineering Superiority in Load Management

Contemporary industrial skates feature:

- High-grade alloy steel construction (200-300 HB hardness)

- Hydrostatic bearing systems reducing friction by 62%

- Smart load sensors with ±1.5% measurement accuracy

- Modular designs supporting 50-1,200 ton capacities

Manufacturer Performance Comparison

| Brand | Max Load (tons) | Steel Grade | Control System | Price Index |

|---|---|---|---|---|

| HeavyLift Pro | 1,200 | ASTM A572 | Digital Hydraulic | 92 |

| MegaMover | 850 | EN 10025 | Analog Pneumatic | 78 |

| PowerSkate | 600 | DIN 17100 | Manual Lever | 65 |

Tailored Solutions for Unique Challenges

Custom configurations address:

- Non-standard load geometries (LxWxH variance >35%)

- Combined rolling/sliding movement requirements

- Explosion-proof environments (ATEX Zone 1/21)

- Sub-millimeter positioning accuracy needs

Operational Success Stories

A recent automotive plant expansion utilized 48 skates to reposition 740-ton stamping presses, achieving:

- 92% faster relocation vs. traditional methods

- 0.38mm average positioning error

- 37% cost reduction per equipment move

Ensuring Long-Term Reliability

Proper maintenance protocols extend service life by 40-60%:

- Bi-weekly bearing lubrication (ISO VG 220 oil)

- Quarterly structural inspections (UT testing >2mm resolution)

- Annual load testing at 110% rated capacity

Optimizing Operations Through Advanced Industrial Skates

Implementing modern industrial machine skates reduces equipment downtime by 55% and improves floor space utilization by 28%. Leading manufacturers now offer IoT-enabled systems providing real-time load analytics, creating new opportunities for operational efficiency in heavy industries.

(industrial machine skates)

FAQS on industrial machine skates

Q: What are industrial machine skates used for?

A: Industrial machine skates are designed to safely transport heavy machinery and equipment within factories, warehouses, or construction sites. They enable precise positioning and reduce manual labor during relocation tasks.

Q: What weight capacity do industrial skates for moving heavy equipment typically support?

A: Most industrial skates can handle loads ranging from 1 ton to 100+ tons per skate, depending on their design. Heavy-duty models often feature reinforced steel construction for extreme weights.

Q: How do industrial movers ensure stability when using machine skates?

A: Industrial movers use skates with swivel or fixed casters, load-distributing bases, and locking mechanisms. Proper alignment and even weight distribution across multiple skates prevent tipping or shifting.

Q: Can industrial machine skates work on uneven surfaces?

A: Some heavy-duty skates are engineered with adjustable height or polyurethane wheels to navigate minor uneven floors. However, extremely rough terrain may require specialized transporters.

Q: What safety features should I look for in industrial skates?

A: Prioritize skates with brake systems, non-slip plates, and durable wheel locks. Regular inspections for wear and tear, combined with operator training, further enhance safety during heavy equipment movement.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

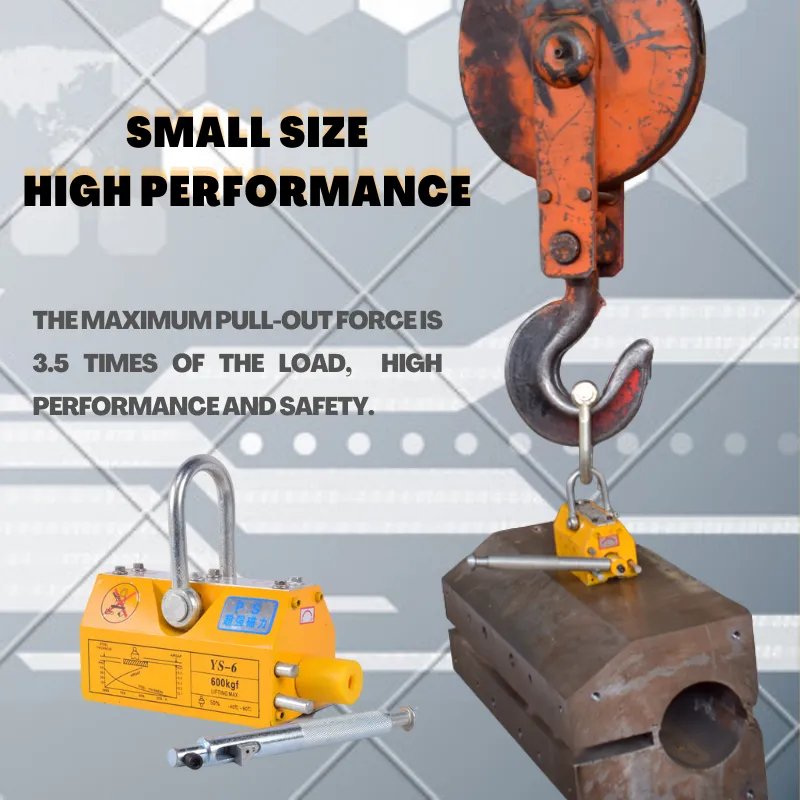

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025